Composite photocatalyst Bi2O3/g-C3N4 as well as preparation method and application of composite photocatalyst

A technology of g-c3n4 and composite light, which is applied in the chemical field, can solve the problems of no degradation of pollutants and poor degradation of NO, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

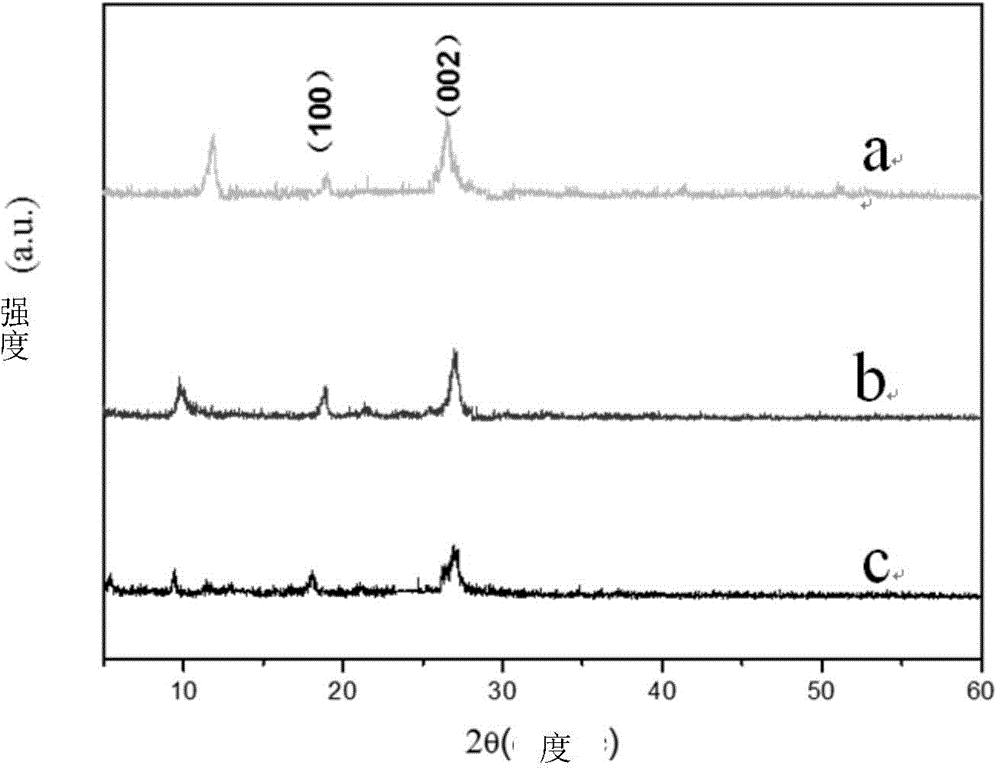

[0076] Weigh 5.0 g of thiourea, place it in a clean porcelain crucible, cover it, and calcinate it in a muffle furnace at 450 °C for 2 h to obtain g-C 3 N 4 Sample (No. 1), its XRD spectrum is as figure 1 Shown in a.

Embodiment 2

[0078] Weigh 5.0 g of urea, place it in a clean porcelain crucible, cover it, and calcinate it in a muffle furnace at 450 °C for 2 hours to obtain g-C 3 N 4 Sample (No. 2), its XRD spectrum is as figure 1 Shown in b.

Embodiment 3

[0080] Weigh 5.0 g of dicyandiamide, place it in a clean porcelain crucible, cover it, and calcinate it in a muffle furnace at 450°C for 2 hours to obtain g-C 3 N 4 Sample (No. 3), its XRD spectrum is asfigure 1 As shown in c.

[0081] figure 1 The g-C that above embodiment 1-3 makes is given 3 N 4 It can be seen from the figure that the catalyst sample presents a crystalline phase structure after calcination, and the two XRD diffraction peaks near 18.2° and 27.3° are respectively assigned to g-C 3 N 4 The crystal plane diffraction peaks of (100) and (002) in the structure are the identification of g-C 3 N 4 characteristic diffraction peaks. The g-C prepared by using dicyandiamine, thiourea, and urea as precursors respectively 3 N 4 The structure is consistent. figure 1 It is also shown that g-C prepared by thiourea calcined at 450 °C for 2 3 N 4 The stronger X-ray diffraction peaks indicated that thiourea was used as a precursor to synthesize photocatalysts with b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com