A Forging Forming Process of Super-large Aluminum Alloy Rectangular Ring

A forging forming and super-large-sized technology, which is applied in the forging and forming process of super-large-sized aluminum alloy rectangular rings. Radial elongation, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

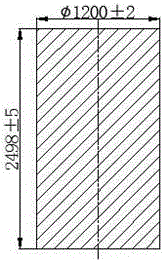

[0035] The first step: blanking: use a cast aluminum rod as the blank, the material of the blank is 2219, the diameter of the blank is 1200±2mm, and the length is 2498±5mm. In this embodiment, the diameter is 1200mm and the height is 2498mm.

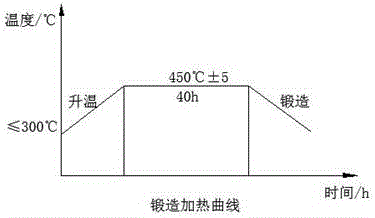

[0036] The second step: heating before the first forging: the first heating stage: put the billet described in the first step into the heating furnace, and raise the temperature of the billet to within 300°C; the second heating stage: as figure 2 As shown, continue to heat the billet from the end temperature of the first heating stage, raise the temperature of the billet to 455° C., and keep the temperature for 40 hours.

[0037] The third step: billet making;

[0038] Blank making includes the following processes:

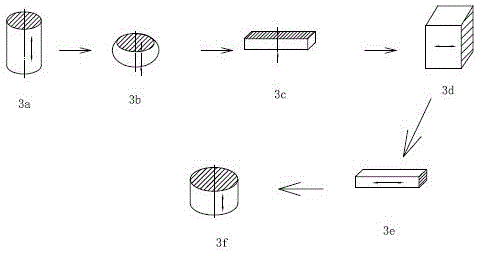

[0039] The first stage: using the cross-upsetting forging method to upset the heated billet to form a round cake. The specific process of the cross-upsetting forging method is as follows: image 3 As shown, the initial d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com