Method for preparing carbon nanohorn with electric arc method

A technology of carbon nanohorn and arc method, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex operation of carbon nanohorn, achieve low production cost, high product purity, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

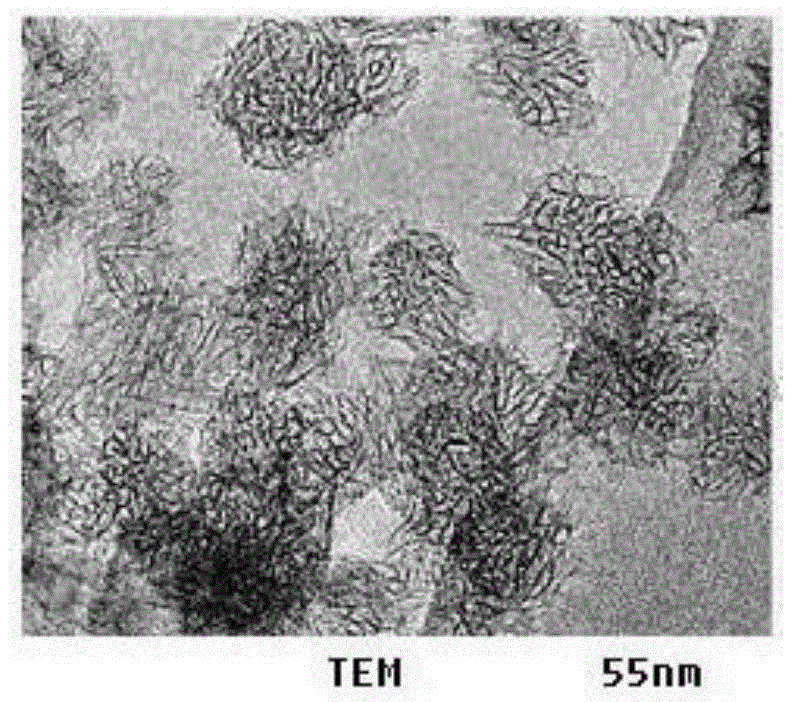

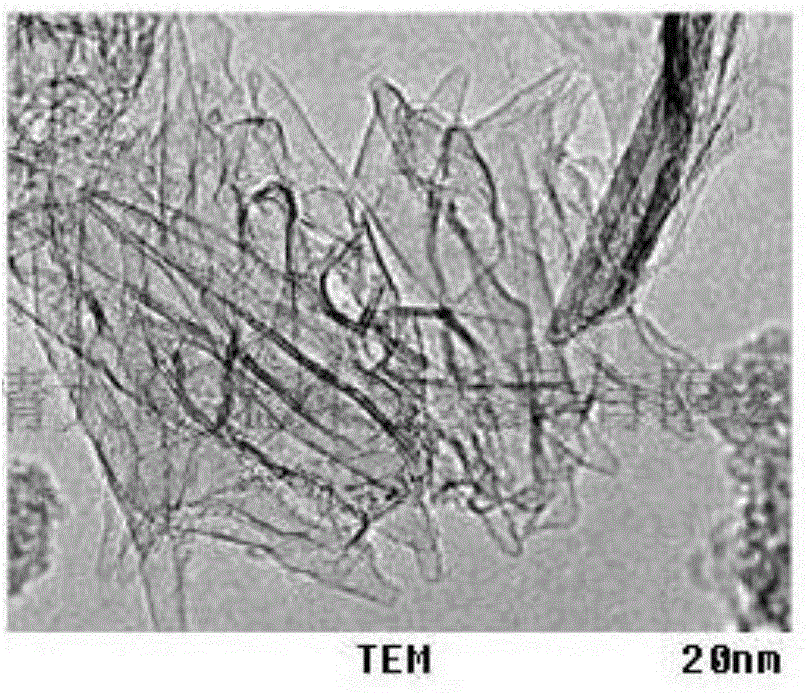

Image

Examples

Embodiment 1

[0022] A method for preparing carbon nanohorns by an electric arc method, using graphite rods as the cathode and anode poles of the carbon nanohorns prepared by the arc method, the anode and cathode poles are placed oppositely, and DC arc discharge is carried out under high current and compressed air atmosphere, during the DC arc discharge process In the process, the anode graphite rod was continuously consumed, and the distance between the cathode and anode was kept at 2nm to obtain carbon nanohorns.

[0023] Among them, the graphite rod is a square spectrum graphite electrode, and the size of the square spectrum graphite electrode is 30mm*30mm*310mm.

[0024] Among them, during DC arc discharge, the discharge current is 1500A, and the pressure of the compressed air atmosphere is -3.5*10 -2 MPa, the arc burning temperature is 2200°C.

[0025] Wherein, the obtained carbon nanohorn is burned in the air to remove a small amount of amorphous carbon in the nanographene, and the b...

Embodiment 2

[0027] A method for preparing carbon nanohorns by an electric arc method, using graphite rods as the cathode and anode poles of the carbon nanohorns prepared by the arc method, the anode and cathode poles are placed oppositely, and DC arc discharge is carried out under high current and compressed air atmosphere, during the DC arc discharge process In the process, the anode graphite rod was continuously consumed, and the distance between the cathode and anode was kept at 1nm to obtain carbon nanohorns.

[0028] Among them, the graphite rod is a square spectrum graphite electrode, and the size of the square spectrum graphite electrode is 30mm*30mm*310mm.

[0029] Among them, during DC arc discharge, the discharge current is 1000A, and the pressure of the compressed air atmosphere is -3*10 -2 MPa, the arc burning temperature is 2000°C.

[0030] Wherein, the obtained carbon nanohorn is burned in the air to remove a small amount of amorphous carbon in the nanographene, and the bur...

Embodiment 3

[0032] A method for preparing carbon nanohorns by an electric arc method, using graphite rods as the cathode and anode poles of the carbon nanohorns prepared by the arc method, the anode and cathode poles are placed oppositely, and DC arc discharge is carried out under high current and compressed air atmosphere, during the DC arc discharge process In the process, the anode graphite rod was continuously consumed, and the distance between the cathode and anode was kept at 3nm to obtain carbon nanohorns.

[0033] Among them, the graphite rod is a square spectrum graphite electrode, and the size of the square spectrum graphite electrode is 30mm*30mm*310mm.

[0034] Among them, during DC arc discharge, the discharge current is 2000A, and the pressure of the compressed air atmosphere is -4*10 -2 MPa, the arc burning temperature is 2500°C.

[0035] Wherein, the obtained carbon nanohorn is burned in the air to remove a small amount of amorphous carbon in the nanographene, and the bur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com