Ionic liquid functionalized ultra-crosslinking polymer as well preparation method and application thereof

An ionic liquid and super-cross-linking technology, applied in separation methods, chemical instruments and methods, educts, etc., can solve problems such as difficult preparation conditions and poor chemical and physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

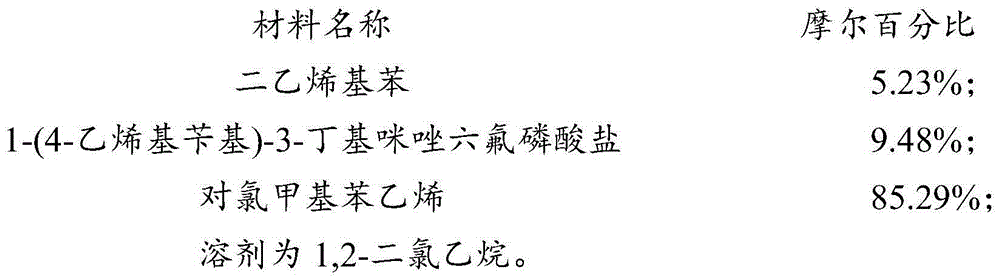

[0021] An ionic liquid functionalized super cross-linked polymer has specific configuration components, the proportions are as follows:

[0022]

[0023] Specific preparation method: First, under the protection of nitrogen, add 0.859g of imidazole-type ionic liquid 1-(4-vinylbenzyl chloride)-3-butylimidazole hexafluorophosphate into a 100ml three-necked flask, and then add 15ml of absolute ethanol. Raise the temperature to 50°C and stir it magnetically. After it is completely dissolved, add 3.058g of p-chloromethylstyrene, 0.16g of divinylbenzene and 0.2g of azobisisobutyronitrile in sequence, raise the temperature to 78°C, and undergo free radical copolymerization. After 24 hours of reaction, a pale yellow solid is obtained as the precursor. Secondly, under the protection of nitrogen, 1.25g precursor and 40ml 1,2-dichloroethane were sequentially added into a 100ml three-necked flask. After swelling for 2h at room temperature, 1.305g anhydrous ferric chloride was added under ice-...

Embodiment 2

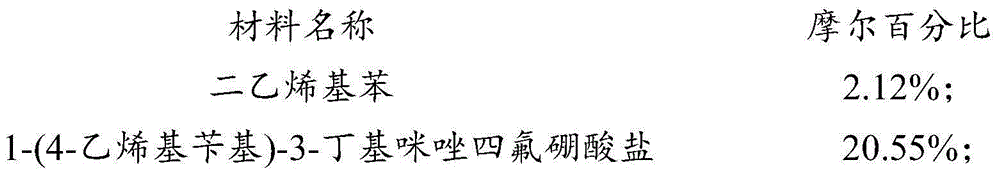

[0026] An ionic liquid functionalized super cross-linked polymer has specific configuration components, the proportions are as follows:

[0027]

[0028]

[0029] The specific preparation method is the same as in Example 1.

[0030] The specific application of 1-(4-vinylbenzyl chloride)-3-butylimidazole tetrafluoroborate ionic liquid functionalized hypercrosslinked polymer: The pore size of the material is 1.5nm, under the conditions of 273K and 1bar, CO 2 The adsorption capacity is 8.49wt%, CO 2 The isometric heat of adsorption is 32.8KJ / mol, and the gas adsorption selectivity (CO 2 / N 2 ) Is 73.

Embodiment 3

[0032] An ionic liquid functionalized super-crosslinked polymer is specifically formulated as a drug, and the ratio is as follows:

[0033]

[0034] The specific preparation method is the same as in Example 1.

[0035] The specific application of 1-(4-vinylbenzyl chloride)-3-butylimidazole hexafluorophosphate ionic liquid functionalized hypercrosslinked polymer: The pore size of the material is 1.7nm, and under the conditions of 273K and 1bar, CO 2 The adsorption capacity is 12.11wt%, CO 2 Isometric heat of adsorption is 35.7KJ / mol, gas adsorption selectivity (CO 2 / N 2 ) Is 89.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com