Nylon composite material with high transparency and low temperature cracking resistance and preparation method thereof

A nylon composite material and high transparency technology, which is applied in the field of nylon composite materials and its preparation, can solve problems such as the negative impact of transparency, and achieve the effect of simple implementation, good compatibility, and large space for raw material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

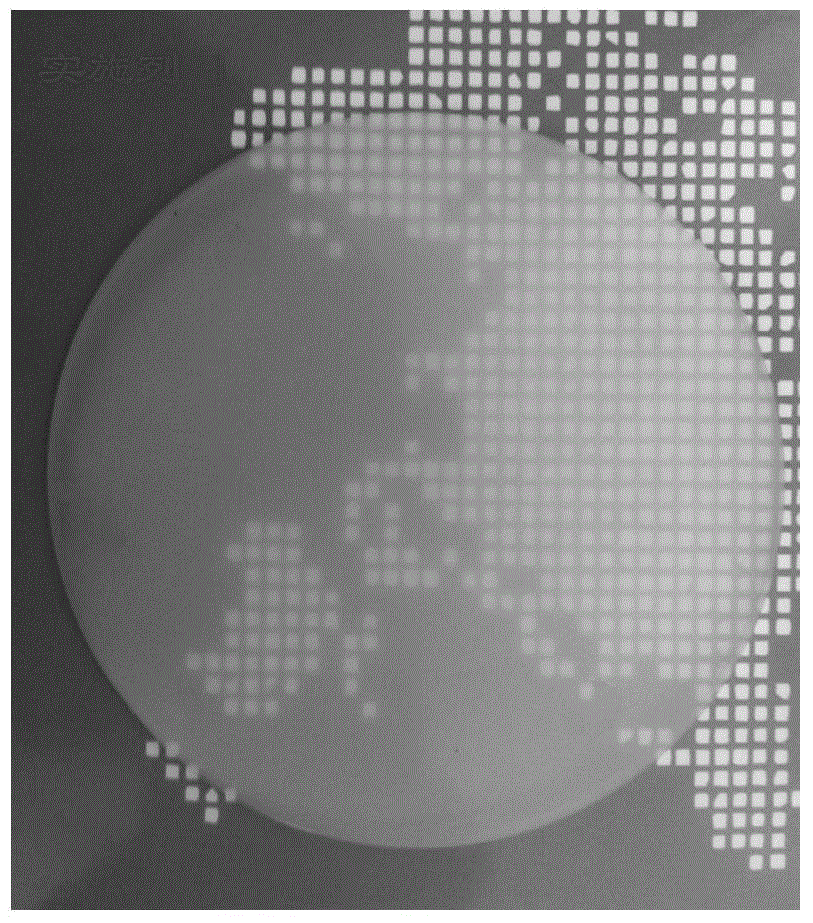

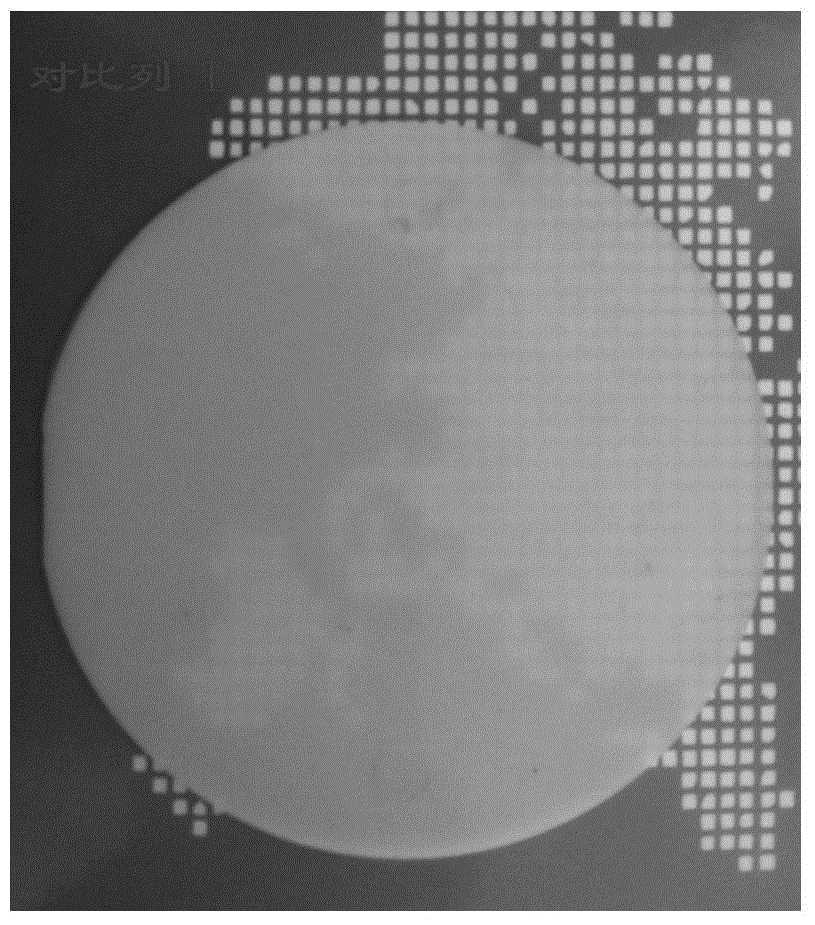

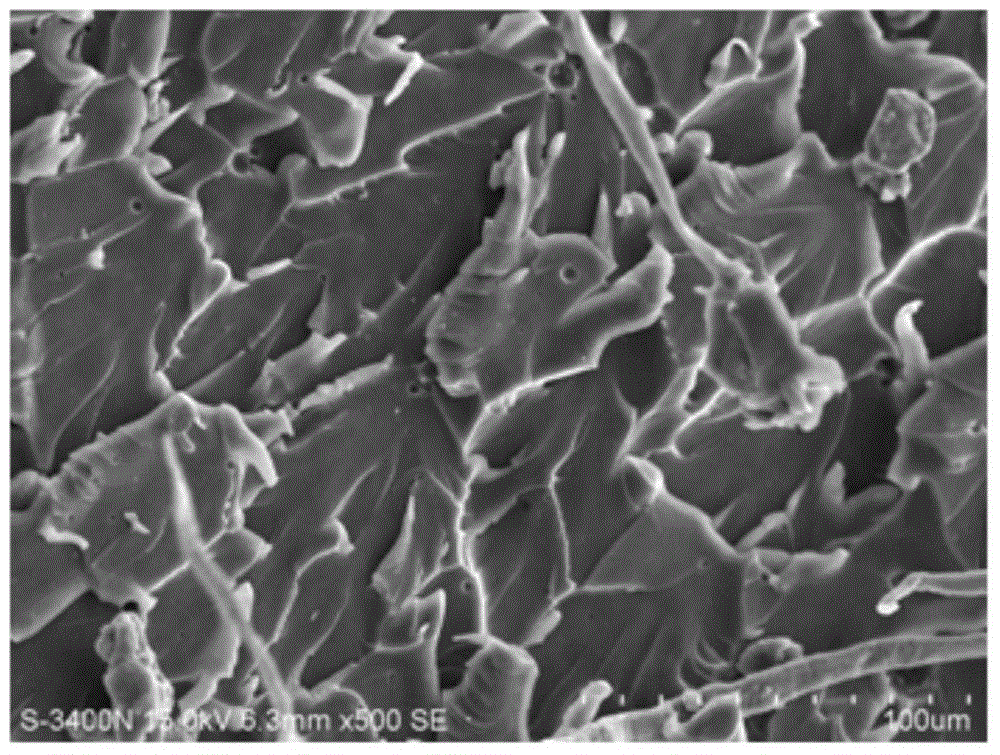

Image

Examples

Embodiment 1

[0038] The preparation method of high-transparency, low-temperature cracking-resistant nylon composite material comprises the following steps:

[0039] Step 1, prepare raw materials according to the following parts by weight:

[0040]

[0041] Step 2, place the nylon in a blast drying oven, and dry it at 110°C for 3 hours;

[0042] Step 3, adding the polar liquid rubber and nylon into the high-mixer and blending for 10 minutes to obtain a uniform premix;

[0043] Step 4, adding a nucleating agent, a lubricant and an antioxidant to the premixed material in the blender, and blending for 20 minutes to obtain a formula;

[0044] Step 5: Put the formulation obtained in Step 4 into a twin-screw extruder for extrusion and granulation. The main engine speed of the extruder is 40HZ, the feeding speed is 12.5HZ, and the temperature of the barrel is set at 240-255°C.

Embodiment 2

[0046] A method for preparing a high-transparency, low-temperature cracking-resistant nylon composite material, comprising the following steps:

[0047] Step 1, prepare raw materials according to the following parts by weight:

[0048]

[0049] Step 2, place the nylon in a blast drying oven, and dry it at 110°C for 5 hours;

[0050] Step 3, adding the polar liquid rubber and nylon into the high-mixer and blending for 20 minutes to obtain a uniform premix;

[0051] Step 4, adding a nucleating agent, a lubricant and an antioxidant to the premix in the blender, and blending for 30 minutes to obtain a formula;

[0052] Step 5: Put the formulation obtained in Step 4 into a twin-screw extruder for extrusion and granulation. The speed of the extruder host is 35HZ, the feed speed is 14HZ, and the temperature of the barrel is set at 230-250°C.

Embodiment 3

[0054] The preparation method of high-transparency, low-temperature cracking-resistant nylon composite material comprises the following steps:

[0055] Step 1, prepare raw materials according to the following parts by weight:

[0056]

[0057] Step 2, place the nylon in a blast drying oven, and dry it at 100°C for 3 hours;

[0058] Step 3, adding the polar liquid rubber and nylon into the high-mixer and blending for 15 minutes to obtain a uniform premix;

[0059] Step 4, adding a nucleating agent, a lubricant and an antioxidant to the premix in the blender, and blending for 30 minutes to obtain a formula;

[0060] Step 5: Put the formulation obtained in Step 4 into a twin-screw extruder for extrusion and granulation. The speed of the main machine of the extruder is 35HZ, the speed of feeding is 12.5HZ, and the temperature of the barrel is set at 210-225°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com