Method of utilizing coenzyme regeneration and resin in-situ extraction to promote hydroxylation of DHEA by Colletotrichum lini ST-1

A resin and extraction technology, applied in the biological field, can solve the problem of small increase in conversion rate and achieve high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 Determination of the type of macroporous adsorption resin

[0018] Add an appropriate amount of substrate or product to 30 ml / 250 mL aqueous solution, equilibrate on a shaker at 220 rpm for 2 h until the solution is saturated, and let stand to separate the supernatant. Then add 1 g of different types of resins, including H103, D101, AB8, HP20, HZ801, and DA201 (selected according to the polarity of the substrate and product), to the substrate and product supernatant, and then place it on a 220 rpm shaker to balance 2 h until the resin reaches adsorption equilibrium. The adsorbed resin was extracted with ethyl acetate, and the adsorption amount of the resin to the substrate and product was calculated after liquid phase analysis, and finally the resin with high affinity to the product and low affinity to the substrate was selected for subsequent conversion experiments.

Embodiment 2

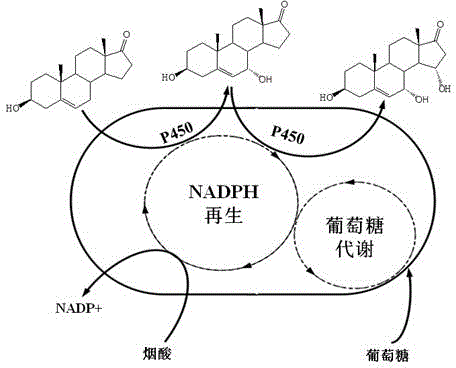

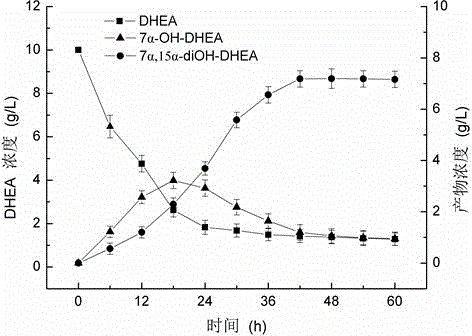

[0019] Example 2 Coenzyme regeneration and resin in-situ extraction "two-in-one" strategy promotion C. lini Hydroxylation of DHEA by ST-1

[0020] (1) Preparation C. lini Cell liquid culture of ST-1 strain

[0021] Pick a loop of the Neptonia flaxensis strain on the solid PDA medium, inoculate it in a 250 mL Erlenmeyer flask containing 30 mL of seed medium, place it on a shaker at 200 r / min at 30 °C Cultivate for 20-24 h to the logarithmic phase, that is, to obtain C. lini Liquid culture of ST-1 cells.

[0022] (3) The composition and ratio of the fermentation medium are: glucose 20-50 g / L; yeast powder 10-30 g / L; peptone 5-20 g / L; corn steep liquor 3-10 g / L; NaCl 0.2-2 g / L; K 2 HPO 4 0.1-1.0 g / L; MgSO 4 0.1-1 g / L; FeSO 4 7H 2 O 0.01-0.10 g / L; pH 6.5-7.5, sterilized under high-pressure steam at 121°C for 20 min.

[0023] (4) Shake flask fermentation: mix the above C. lini Cell liquid culture of ST-1 strain was inoculated at an inoculum size of 8-10% (w / w) in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com