Method for preparing nanofiber by electrostatic spinning, nanofiber obtained with method and application of nanofiber

A technology of electrospinning and nanofibers, which is applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc. It can solve the problems of difficult solvent recovery and adverse effects of nanofiber materials, and achieve good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

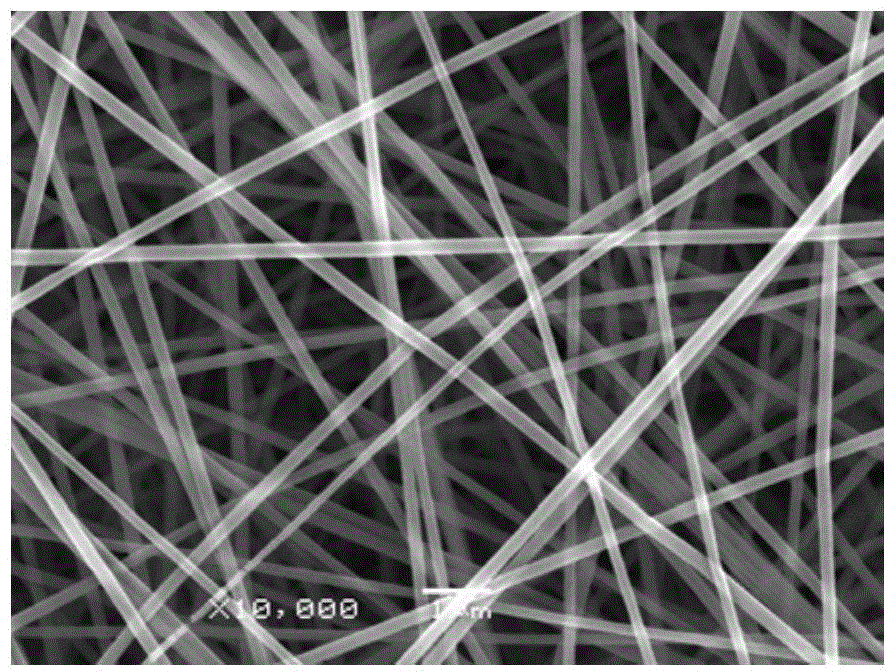

[0018] Take by weighing 0.1g gelatin and 0.3g pullulan and be dissolved in 2ml deionized water with electronic balance, obtain the aqueous solution that mass volume ratio concentration is 20 (m / v)%, pullulan / gelatin mixing ratio is 75 / 25, will The solution was magnetically stirred at room temperature for 12 hours to dissolve completely; after standing for five minutes, it was electrospun, and the electrospinning parameters were: electrostatic voltage 20kv, receiving distance 11cm, and spinning speed 0.5ml / h. Receive it with aluminum foil, and finally obtain a non-woven fabric material with an average fiber diameter of 175 nm.

Embodiment 2

[0020] Take by weighing 0.16g gelatin and 0.32g pullulan with electronic balance and be dissolved in 2ml deionized water, obtain the aqueous solution that mass volume ratio concentration is 24 (m / v)%, pullulan / gelatin mixing ratio is 66 / 34, will The solution was magnetically stirred at room temperature for 12 hours to dissolve completely; after standing for five minutes, it was electrospun, and the electrospinning parameters were: electrostatic voltage 20kv, receiving distance 11cm, and spinning speed 0.5ml / h. Receive it with aluminum foil, and finally obtain a non-woven fabric material with an average fiber diameter of 179 nm.

Embodiment 3

[0022] Weigh 0.25 g of gelatin and 0.25 g of pullulan with an electronic balance and dissolve in 2 ml of deionized water to obtain an aqueous solution with a mass volume ratio concentration of 25% and a mixing ratio of pullulan / gelatin of 50 / 50, and magnetically stir the solution at room temperature Dissolve completely in 12 hours; after standing for five minutes, electrospinning, the electrospinning parameters are: electrostatic voltage 20kv, receiving distance 11cm, spinning speed 0.5ml / h. Receive it with aluminum foil, and finally obtain a non-woven fabric material with an average fiber diameter of 141 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com