Low temperature pretreatment process of soybean fiber fabric

A soybean fiber and pretreatment technology, applied in textiles, papermaking, bleaching products, etc., can solve the problems of poor water solubility, high price, affecting the use of refining and bleaching agents, and achieve the effect of reducing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

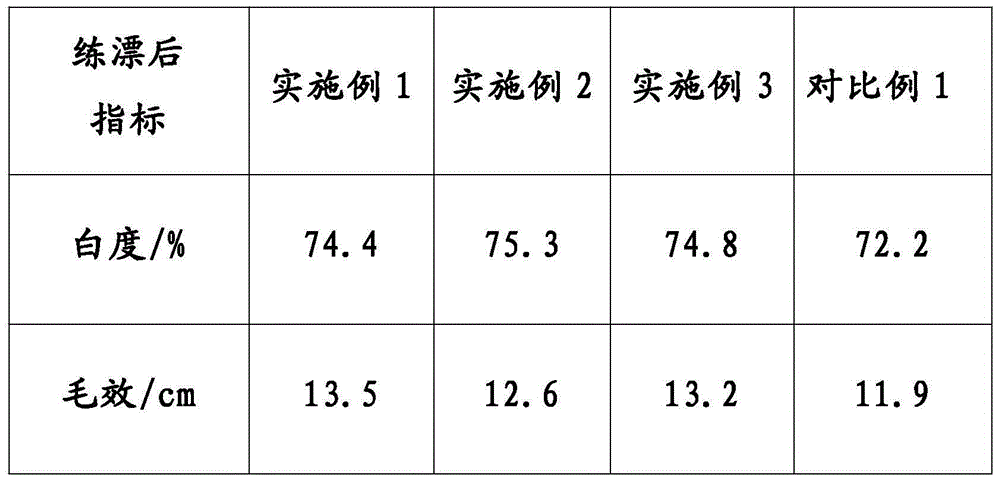

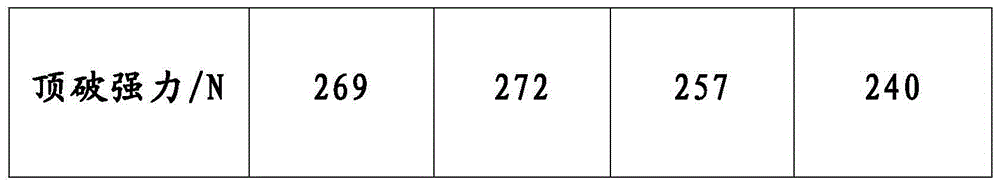

Examples

Embodiment 1

[0025] (1) The soybean fiber fabric is 38s woven fabric.

[0026] (2) The low-temperature scouring and bleaching agent comprises the following components in parts by weight:

[0027] Tea saponin 30,

[0028] Sodium perborate 20,

[0029] 2,2-bipyridine 1,

[0030] Horseradish Peroxidase 0.1,

[0031] Sodium Alginate 3.

[0032] The preparation method of low-temperature scouring and bleaching agent is as follows:

[0033] Add 2,2-bipyridine and horseradish peroxidase into the aqueous solution according to the above weight parts, and then use spray drying to atomize the above aqueous solution to form small droplets, which are quickly evaporated by high temperature to form a composition as the core , sodium alginate shell microcapsule powder. Control the diameter of the powder to be between 250 μm, then add microcapsule powder, tea saponin, and sodium perborate into a powder mixer, stir for 30 minutes, and discharge.

[0034] (3) The low temperature scouring and bleaching ...

Embodiment 2

[0037] (1) The soybean fiber fabric is 38s woven fabric.

[0038] (2) The low-temperature scouring and bleaching agent comprises the following components in parts by weight:

[0039] Tea Saponin 50,

[0040] Sodium perborate 40,

[0041] 2,2-bipyridine 3,

[0042] Horseradish Peroxidase 0.5,

[0043] Sodium alginate 6.

[0044] The preparation method of low-temperature scouring and bleaching agent is with reference to embodiment 1

[0045] (3) The low temperature scouring and bleaching process is

[0046] Soybean protein fabrics are soaked in 10g / L low-temperature scouring and bleaching agent, with a residual rate of 80%, steamed in a steamer at 70°C for 50min, washed with water, and dried.

Embodiment 3

[0048] (1) The soybean fiber fabric is 38s woven fabric.

[0049] (2) The low-temperature scouring and bleaching agent comprises the following components in parts by weight:

[0050] Tea Saponin 40,

[0051] Sodium perborate 30,

[0052] 2,2-bipyridine 2,

[0053] Horseradish Peroxidase 0.25,

[0054] Sodium Alginate 4.

[0055] The preparation method of low-temperature scouring and bleaching agent is with reference to embodiment 1

[0056] (3) The low temperature scouring and bleaching process is

[0057] Soybean protein fabrics are soaked in 10g / L low-temperature scouring and bleaching agent, with a residual rate of 70%, steamed in a steamer at 70°C for 50min, washed with water, and dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com