Lifting type sound insulation screen based on changes of wind speeds

A sound insulation barrier and lifting technology, which is applied in the direction of sound insulation, noise absorption devices, building components, etc., can solve the problems affecting the normal operation and maintenance of equipment, the analysis process and the scope of treatment are huge, and the automatic adjustment cannot be realized. Practicality and market prospects, fast data access speed, and the effect of less data volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

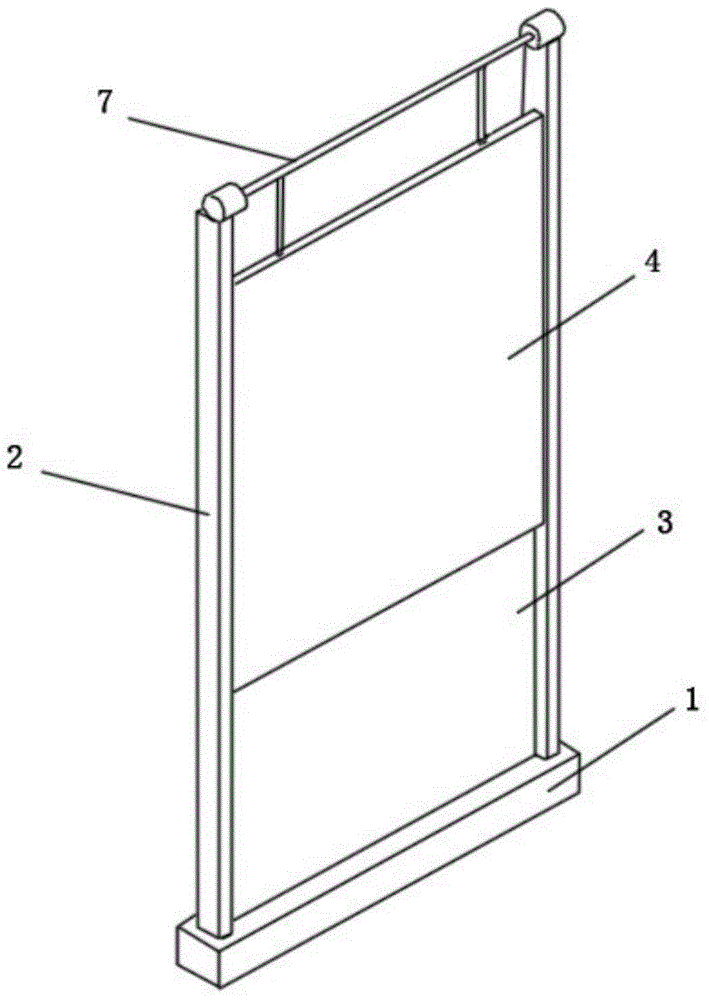

[0050] Embodiment 1: as figure 1 As shown, this embodiment is composed of a base 1, a support frame 2, a fixed sound insulation board 3, a liftable sound insulation board 4, a wind speed sensor 5, a controller 6, a transmission part 7 and a driving part 8, wherein the wind speed sensor 5, The controller 6 and the driver 8 are in figure 1 Not identified in .

[0051] The support frame 2 is fixed on both ends of the base 1 for fixing and supporting the sound insulation board 3 and the movable sound insulation board 4 . At the same time, in order to ensure the structural strength of the sound insulation barrier, the fixed sound insulation board 3 is fixedly connected with the support frame 2 and the base 1 respectively.

[0052] The support frame 2 is provided with a groove, and the liftable sound insulation board 4 slides up and down along the groove to adjust the height of the entire liftable mobile barrier; or, the support frame 2 is provided with convex grooves, and both si...

Embodiment 2

[0060] This embodiment is similar to embodiment 1, and its difference is:

[0061] (1) The transmission part 7 is located under the liftable sound insulation panel 4, and at this time constitutes a "jack-up type", that is, the transmission part 7 controls the lifting of the liftable sound insulation panel 4 in a telescopic manner under the liftable sound insulation panel 4 .

[0062] (2) Since the effect of the wind speed sensor 5 is to accurately and real-time detect the wind speed situation of the environment where the liftable sound insulation barrier is located, especially in coastal areas, when a typhoon comes, the wind speed sensor 5 needs to detect the change of the wind speed in time, And for the controller 6 to respond to environmental changes in time, so the wind speed sensor 5 may not be arranged on the liftable sound insulation barrier, but on an open field close to the liftable sound insulation barrier and without shelter, as long as it can Just meet the above re...

Embodiment 3

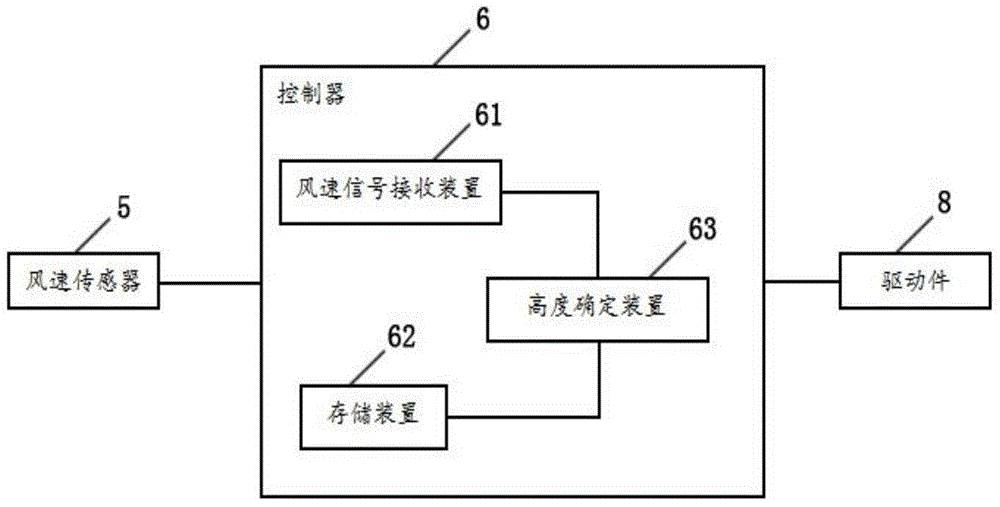

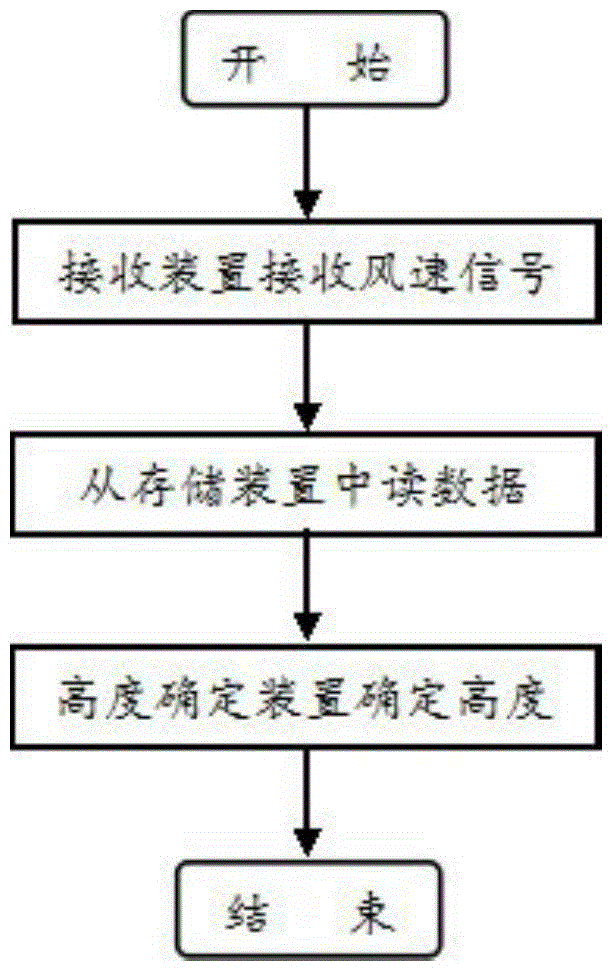

[0065] Such as figure 2 As shown, the controller 6 includes a wind speed signal receiving device 61 , a storage device 62 , and an altitude determination device 63 , and the altitude determination device 63 is connected to the wind speed signal receiving device 61 and the storage device 62 respectively.

[0066] The wind speed signal receiving device 61 is used for receiving the wind speed signal collected by the wind speed sensor 5 .

[0067] The storage device 62 is used for storing each height of the liftable sound insulation panel 4 and the corresponding wind speed critical value.

[0068] Altitude determination device 63, used to compare the size of the wind speed and the critical value of wind speed at the current height, if the wind speed is greater than the critical value of wind speed, then output a control command to drop to the designated height; control instructions.

[0069] In this embodiment, the wind speed critical value is determined by the height of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com