Plug for rolling seamless steel pipe, method for manufacturing said plug, and method for manufacturing seamless steel pipe in which said plug is used

A technology of seamless steel pipe and manufacturing method, which is applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of insufficient high-temperature strength, insufficient service life of the plug, and damage of the front end, etc., and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

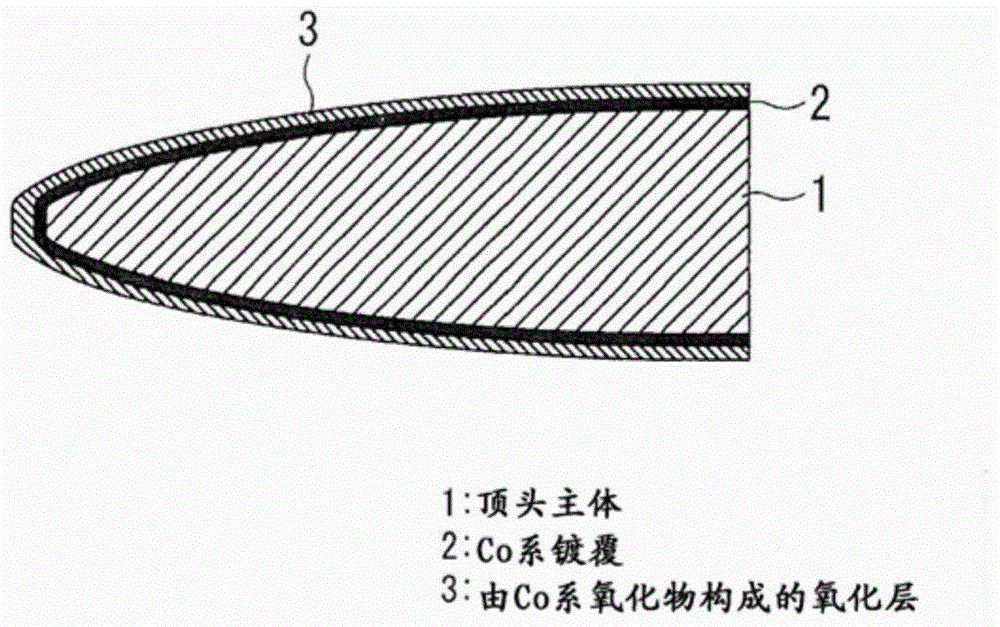

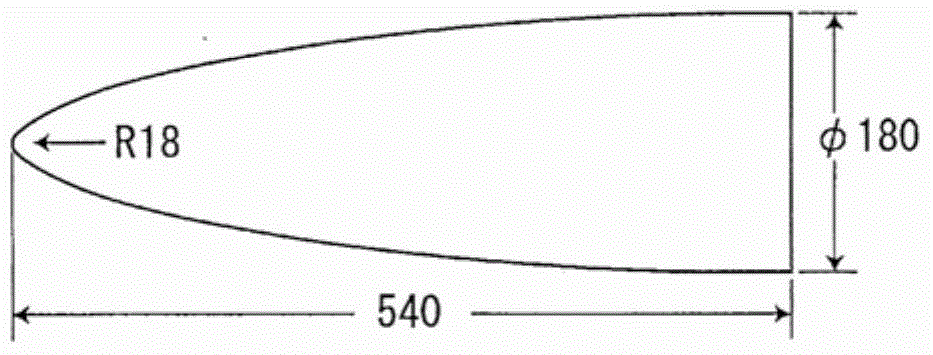

[0053] The technology of the present invention adopts the seamless steel pipe used in the factory figure 2 Dimensions shown for shape of plug.

[0054] In the examples, as the material constituting the plug of the present invention, a low-alloy material containing C: 0.2%, Si: 0.5%, Mn: 1.0%, Cr: 0.8%, Mo: 2.0%, and Nb: 0.1% was used in mass %. alloy steel.

[0055] In the prior art, heat treatment is performed on the plug to form an oxide layer composed of iron-based oxides on the surface.

[0056] A surface photograph of a plug having an iron-based oxide layer formed on its surface by heat treatment suitable for the plug material (heating at 1050°C in the atmosphere and holding for 6 hours) is shown in image 3 . In addition, the microstructure of the cross-section of the iron-based oxide layer is schematically shown in Figure 5 .

[0057] In Example A of the present invention, the plating of Co-0.1 mass % Ni (called pure Co) is implemented on the surface of the iron-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com