Method for regenerating three-way catalyst Pd/Na2O/K2O/C

A three-way catalyst and catalyst technology, which is applied in the direction of catalyst regeneration/reactivation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. It can solve the problem of unsatisfactory performance of recycled products with recovery rate, etc. problem, to achieve the effect of improved performance, good repeatability and stable service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

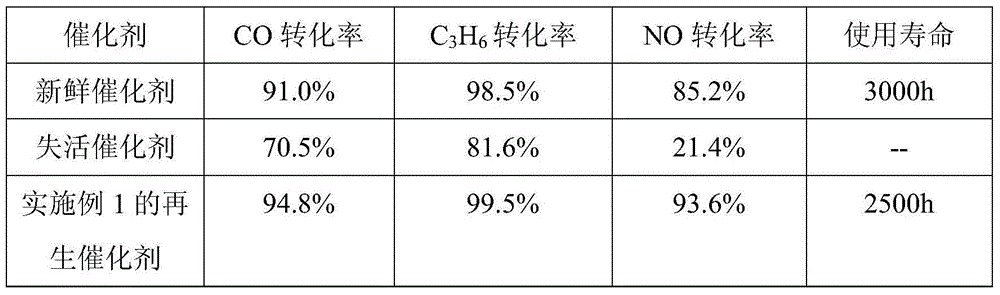

Examples

Embodiment 1

[0015] The deactivated Pd / Na 2 O / K 2 The O / C three-way catalyst is treated as follows:

[0016] (1) The poisoned Pd / Na 2 O / K 2 After the O / C three-way catalyst is washed with water, soak it in a dilute sulfuric acid solution with a mass concentration of 20%, regenerate it under microwave heating for 3 hours, the regeneration temperature is 40°C, and the regeneration solid-liquid ratio is 20g / L, and then dry it at room temperature for 15 hours;

[0017] (2) The catalyst obtained in step (1) is activated and regenerated with plasma of nitrogen and oxygen, and the regeneration conditions are as follows: a pulse power supply is used, the peak voltage is 8kV, the frequency is 150hz, the regeneration time is 2h, and the temperature is 100°C;

[0018] (3) the catalyzer that step (2) obtains is that concentration is 15% H 2 o 2 Soak in the solution for 3 hours, and then dry at 80° C. to obtain a dried three-way catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com