Fusion penetration control method of active shock excitation molten pool of multiple array lasers

A control method and technology of molten pool, applied in laser welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems of welding process and welding process influence, reduction of molten pool oscillation level, etc., to achieve good stability, good repeatability, Not easy to interfere with the effect of external factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

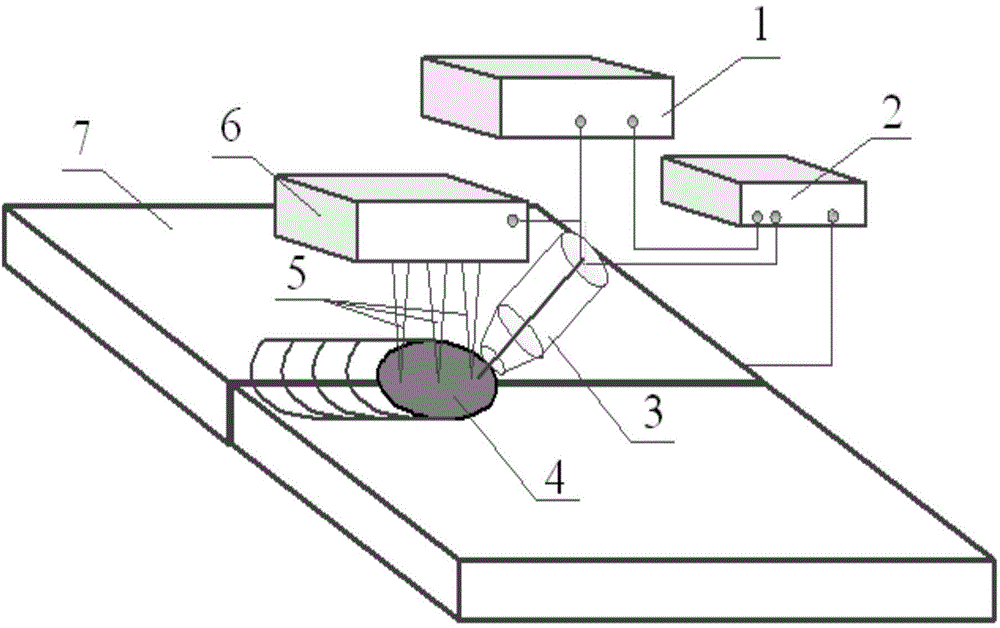

[0023] The equipment used in this embodiment includes: a computer control system 1 , an oscilloscope 2 and a laser beam splitter 6 . The computer control system 1 can control the walking of the welding gun 3 and the laser beam splitter 6 according to the voltage change amplitude curve collected by the oscilloscope 2; the oscilloscope 2 has the function of collecting the arc voltage change curve when the molten pool oscillates; The function of converting a laser beam into a multi-beam array laser.

[0024] Taking the base material 5 as an example for welding Q235 low-carbon steel with a thickness of 5 mm, the laser frequency is 60-80 Hz, and the laser beam splitter 6 emits 3 laser beams that are evenly distributed in the molten pool 4 along the welding direction.

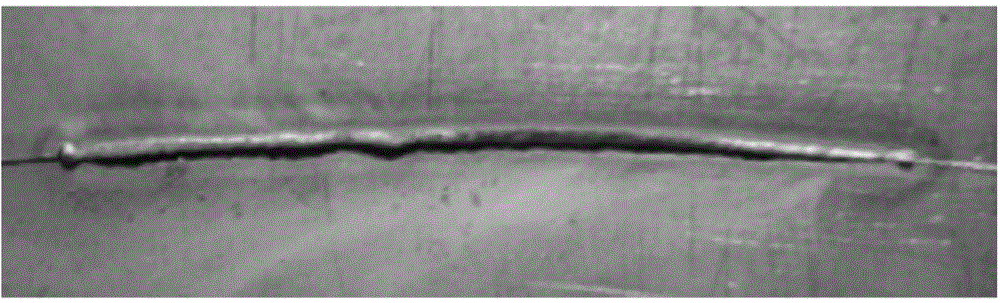

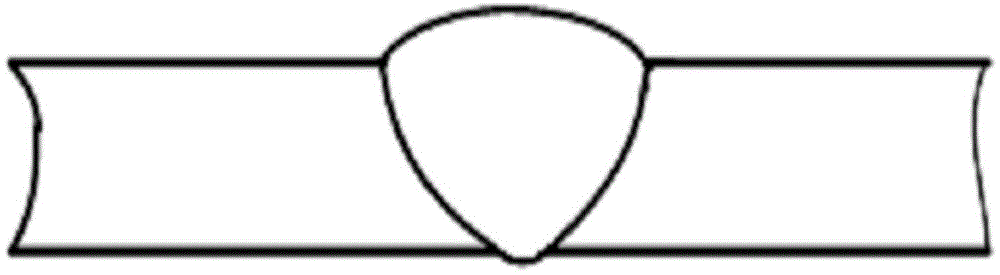

[0025] The welding effect diagram of the embodiment is shown in figure 2 , 3 , the specific laser excitation molten pool penetration control includes the following steps:

[0026] 1. Adjust the spatial position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com