Deep dehydration device and deep dehydration method for organic materials

A deep dewatering, organic material technology, applied in chemical instruments and methods, water/sludge/sewage treatment, energy and wastewater treatment, etc., can solve the problem of high energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

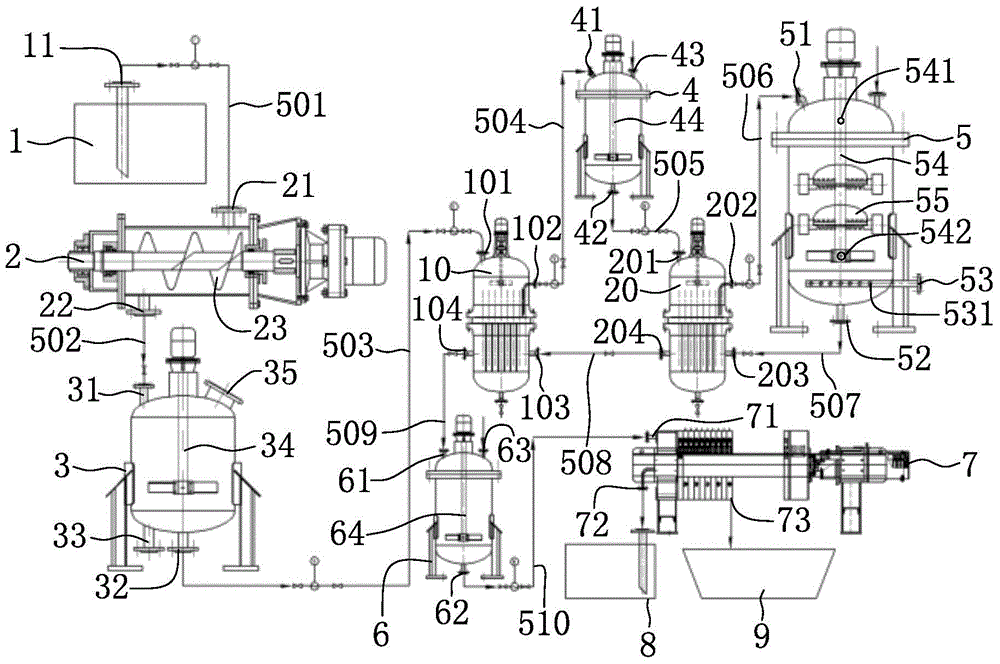

[0049] refer to figure 1 , figure 2 with image 3 , a deep dehydration device for organic materials, comprising:

[0050] Dehydration pretreatment device 2: including a centrifuge or filter press equipment to dehydrate the organic particulate material with a moisture content higher than 90% to a moisture content of 85 to 90%. The dehydration pretreatment device 2 includes a material inlet 21 and a material outlet 22, and additive storage tanks and other material inlets can be added before feeding if necessary;

[0051] Pretreatment tank 3: the pretreatment tank 3 is a vertical barrel-shaped tank, and the pretreatment tank 3 includes a stirring device 34, a feed port 31, a discharge port 32, a first heat recovery device 10 (the first heat recovery device 10 is There are materials with air and steam, and the best choice of equipment is heat pipe heat exchanger, as shown in the figure, the first heat energy recovery equipment 10 can be built in the pretreatment tank 3 and de...

Embodiment 2

[0067] In this embodiment, the organic granular materials are from a county-level city sewage treatment plant to treat mixed sewage containing domestic and industrial second-class. The secondary sewage treatment sedimentation tank produces about 100t (tons) of sludge every day. The test results show that it contains 4.33% of N (on a dry basis), P 2 o 5 2.08% (dry basis), K 2 O 0.55% (on a dry basis), organic matter 35.13% (on a dry basis), cellulose 18% (on a dry basis), a calorific value of 13,300J / g, and a moisture content of 96.0% before pressure filtration. The treatment plant After adding flocculant, it is 82.1%, Ph 7.39, COD 1205mg / g, BOD 125mg / g, Na 0.83%, Cl 0.15%. The elemental analysis results were C 27.46%, N 4.53%, H 4.40%, S 1.15%, and O 21.46%. Heavy metal content in mg / Kg dry basis: Cr 513.86, Pb 23.85, Cd 0.12, As 36.44, Hg 0.36, Cu 160.91, Ni 86.85, Zn 1183.3. Trace organic substances detected by gas chromatography mass spectrometry (GC / MS) are 2,400 phen...

Embodiment 3

[0074] In this embodiment, the biogas residue treatment after anaerobic fermentation treatment of kitchen waste is taken as an example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com