Dimethylolpropionic acid modified waterborne phenolic resin and preparation method thereof

A technology of water-based phenolic resin and dimethylol propionic acid, which is applied in coatings, polyester coatings, etc., can solve the problems of flammability, large VOC emissions, and low safety factor, and achieve environmental protection and environmental protection. , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

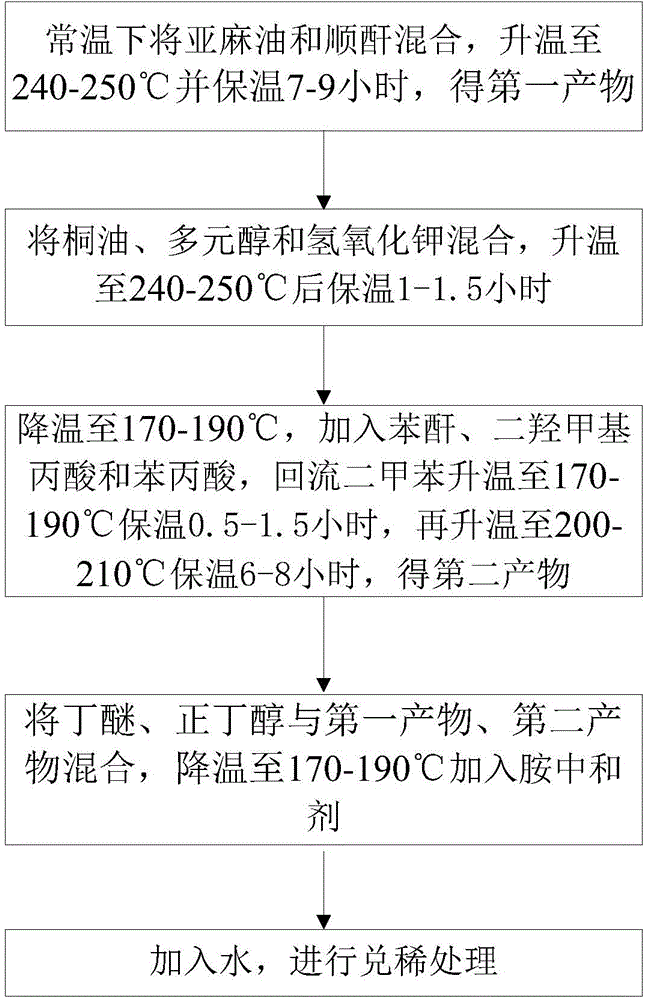

[0023] On the other hand, the present invention provides the preparation method of above-mentioned water-based phenolic resin, figure 1 A schematic flow diagram of the method for preparing the water-based phenolic resin of the present invention is shown. Such as figure 1 Shown, this preparation method comprises the steps:

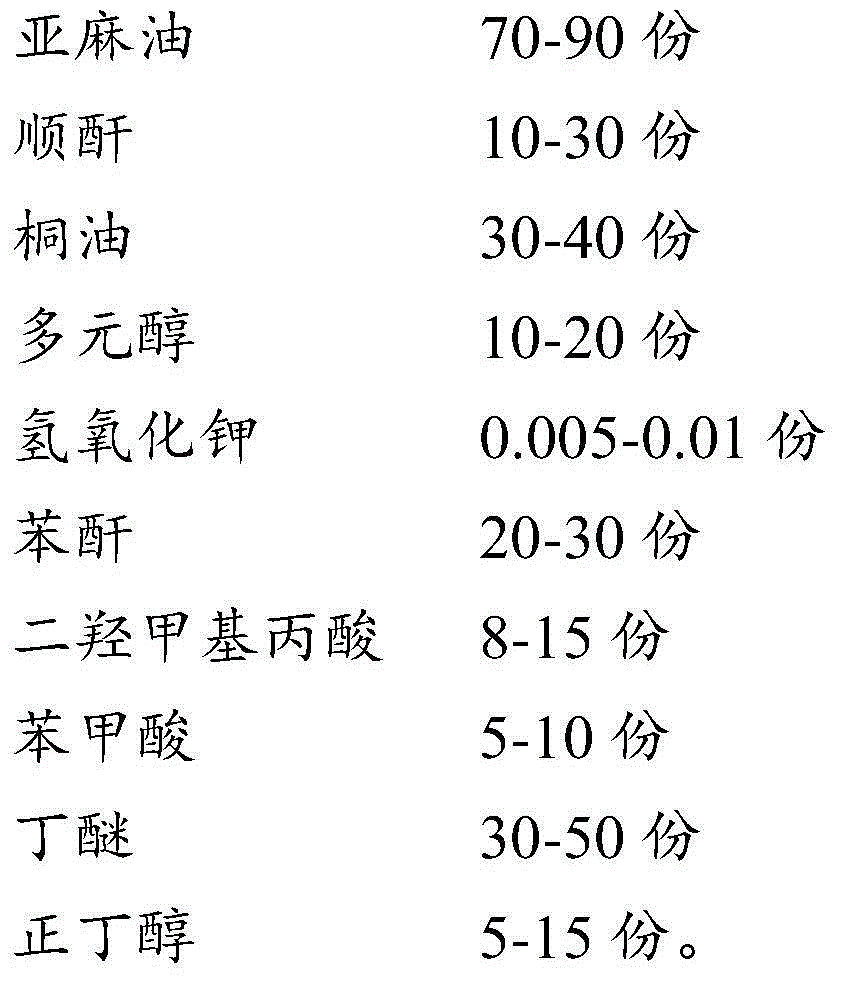

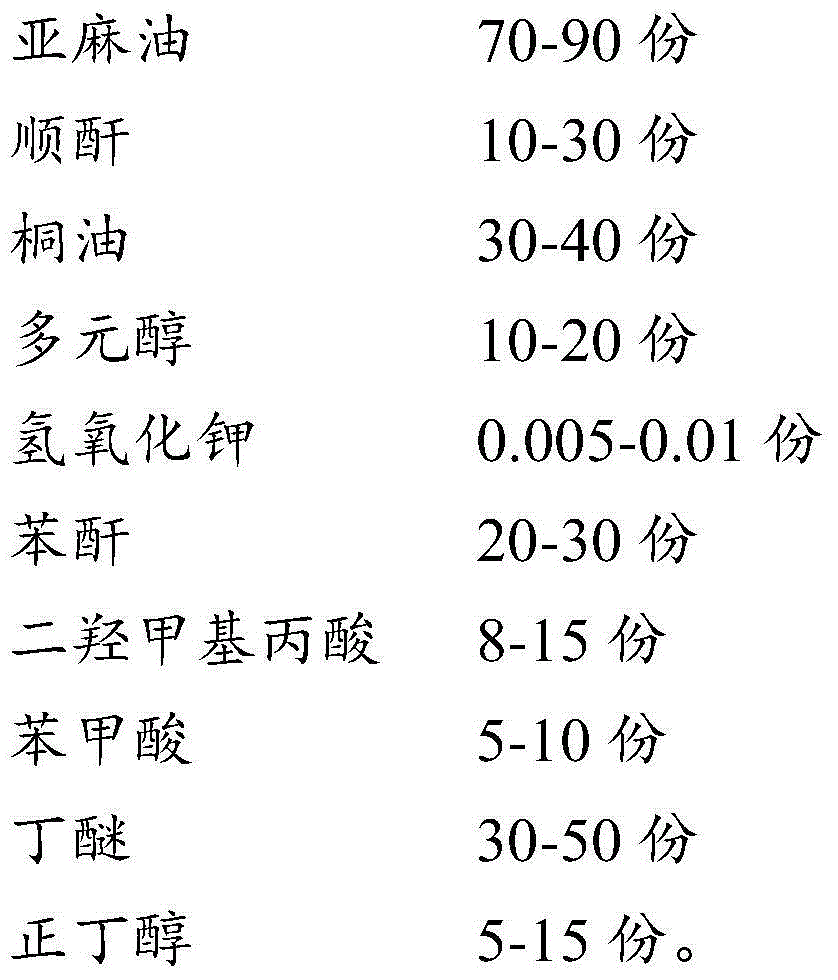

[0024] Step 1: Mix 70-90 parts by weight of linseed oil and 10-30 parts by weight of maleic anhydride at room temperature, raise the temperature to 240-250° C., and keep the temperature for 7-9 hours to obtain the first product;

[0025] Step 2: Mix 30-40 parts by weight of tung oil, 10-20 parts by weight of polyols and 0.005-0.01 parts by weight of potassium hydroxide, heat up to 240-250°C and keep warm for 1-1.5 hours;

[0026] Step 3: Cool the reaction product obtained in step 2 to 170-190°C, add 20-30 parts by weight of phthalic anhydride, 8-15 parts by weight of dimethylol propionic acid and 5-10 parts by weight of benzoic acid, and reflux for two T...

Embodiment 1

[0033] The weight ratio of the raw materials of the water-based phenolic resin in this embodiment is: 70 parts of linseed oil, 10 parts of maleic anhydride, 30 parts of tung oil, 10 parts of pentaerythritol, 0.005 parts of potassium hydroxide, 20 parts of phthalic anhydride, 8 parts of dimethylol propionic acid, 5 parts of benzoic acid, 30 parts of butyl ether, and 15 parts of n-butanol.

[0034] The preparation method of present embodiment phenolic resin is:

[0035] Step 1: Mix linseed oil and maleic anhydride at room temperature, raise the temperature to 240°C, and keep the temperature for 7 hours to obtain the first product;

[0036] Step 2: Mix tung oil, pentaerythritol and potassium hydroxide, raise the temperature to 240°C and keep it warm for 1 hour, alcoholysis reaction occurs;

[0037] Step 3: Cool down the alcoholysis product obtained in step 2 to 170°C, add phthalic anhydride, dimethylolpropionic acid and benzoic acid, reflux the xylene and raise the temperature t...

Embodiment 2

[0041] The raw material weight ratio of the phenolic resin in this embodiment is: 90 parts of linseed oil, 30 parts of maleic anhydride, 40 parts of tung oil, 20 parts of pentaerythritol, 0.01 part of potassium hydroxide, 30 parts of phthalic anhydride, 15 parts of dimethylol propionic acid, benzene 10 parts of formic acid, 50 parts of butyl ether, 5 parts of n-butanol.

[0042] The preparation method of the phenolic resin of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com