Modified rubber compound and preparation method thereof, vulcanized rubber and application thereof

A technology of modified rubber and vulcanized rubber, which is applied in the field of vulcanized rubber to prepare tires, vulcanized rubber, modified rubber compound, and the preparation of modified rubber compound. It can solve the problems of affecting polymerization reaction and difficult removal of small molecules, and achieve excellent Effects of wear resistance, good mechanical properties, and low rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

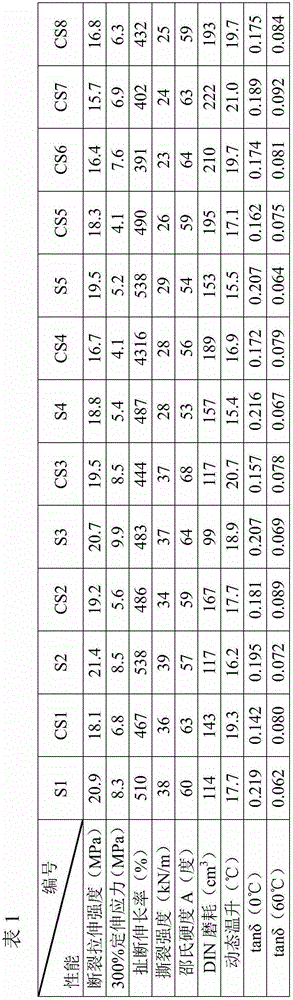

Examples

preparation example Construction

[0015] The invention provides a method for preparing a modified rubber compound, the method comprising: (1) contacting rubber and alkylphenol disulfide for the first time under the first mixing condition to obtain a modified rubber; The first mixing conditions include: the mixing temperature is 70-150°C, and the mixing time is 5-30 minutes; (2) Under the second mixing conditions, the modified rubber, silica and coupling The agent is contacted for the second time to obtain a modified rubber compound. Preferably, the first kneading conditions include: kneading temperature is 120-140° C., and kneading time is 15-25 minutes.

[0016] According to the present invention, contacting the alkylphenol disulfide with the rubber under the mixing conditions can improve the surface properties of the rubber and facilitate the dispersion of the white carbon black when mixed with the white carbon black. The reason may be that the disulfide bond in the alkylphenol disulfide chemically reacts w...

Embodiment 1

[0037] 100 grams of solution-polymerized styrene-butadiene rubber (weight-average molecular weight of 500,000) and 4 grams of p-tert-butylphenol disulfide (Arkema, Vultac2) were first mixed, and the first mixing conditions included: the mixing temperature was 140 °C, the first mixing speed was 45 rpm, and the mixing time was 20 minutes to obtain a modified rubber.

[0038] Then 60 grams of white carbon black (specific surface area is 115m 2 / g) and 4.2 grams of bis-(γ-triethoxysilylpropyl)-tetrasulfide and the above-mentioned modified rubber are mixed for the second time. The second mixing conditions include: the mixing temperature is 155°C, the second The mixing speed was 50 rpm, and the mixing time was 10 minutes to obtain the modified rubber compound M1.

Embodiment 2

[0042] 100 grams of cis-polybutadiene rubber (with a weight average molecular weight of 200,000) and 5 grams of p-tert-amylphenol disulfide (Arkema, Vultac TB7) were first mixed, and the first mixing conditions included: mixing The temperature was 130° C., the first mixing speed was 50 rpm, and the mixing time was 18 minutes to obtain a modified rubber.

[0043] Then 50 grams of white carbon black (specific surface area is 175m 2 / g) and 2.5 grams of bis-(γ-triethoxysilylpropyl)-disulfide are mixed with the above-mentioned modified rubber for the second time. The second mixing conditions include: the mixing temperature is 165°C, the second The mixing speed was 40 rpm, and the mixing time was 15 minutes to obtain the modified rubber compound M2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com