Enhanced semi-aromatic nylon/liquid crystal polymer alloy material and preparation method thereof

A semi-aromatic nylon and liquid crystal polymer technology, applied in the field of engineering plastics, to reduce melt viscosity, increase melt flow rate, and improve processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

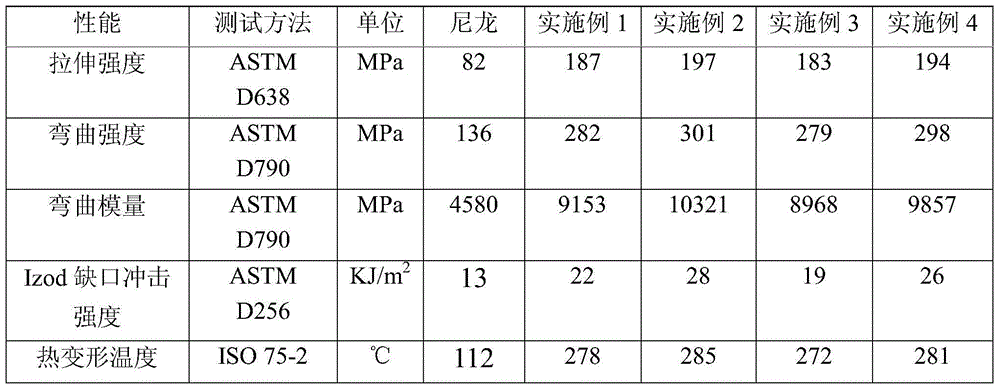

Examples

Embodiment 1

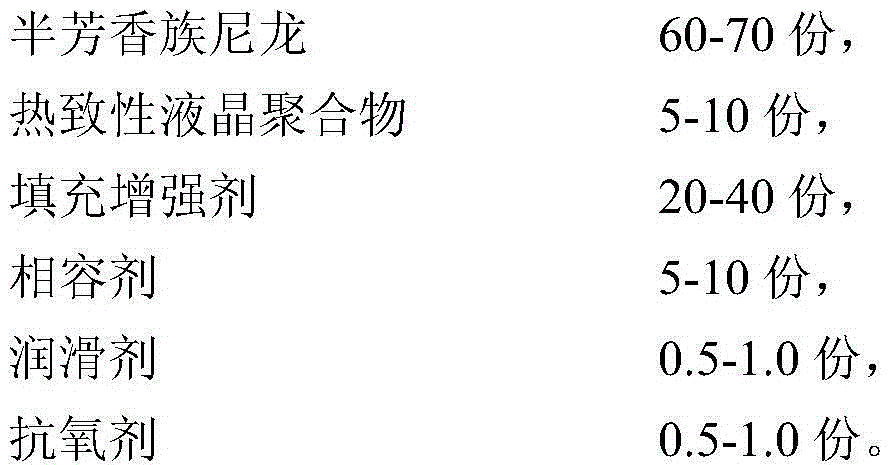

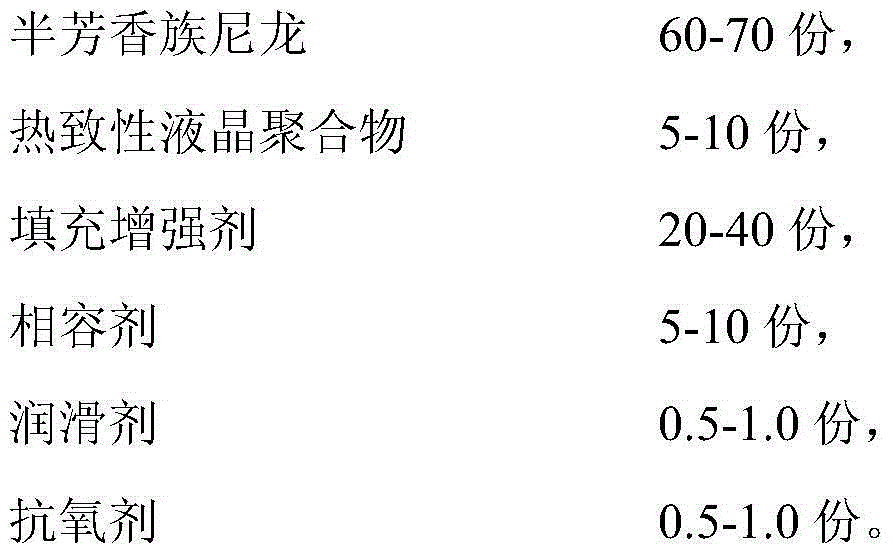

[0029] A reinforced semi-aromatic nylon / liquid crystal polymer alloy material, made of the following raw materials in parts by weight: 60 parts of semi-aromatic nylon PA10T, 5 parts of liquid crystal polymer 5130L, 20 parts of carbon fiber, 5 parts of maleic anhydride, stearic acid 0.5 parts of calcium lubricant, 0.5 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester of antioxidant.

[0030] Preparation:

[0031] (1) Semi-aromatic nylon resin and liquid crystal polymer are air-dried at 120-130°C and 140-150°C for 8-10 hours respectively;

[0032] (2) Use a high-speed mixer to mix the lubricant, antioxidant and compatibilizer at high speed, and then put it in a drying oven for drying. The drying temperature is 90-100°C, and the drying time is 1-3 hours;

[0033] (3) Put the raw materials in step (1) and step (2) into a high mixer and mix them for 5-10 minutes;

[0034] (4) Add the raw materials mixed in step (3) from the main feeding po...

Embodiment 2

[0036] A reinforced semi-aromatic nylon / liquid crystal polymer alloy material, made of the following raw materials in parts by weight: 70 parts of semi-aromatic nylon PA10T, 10 parts of liquid crystal polymer 5130L, 40 parts of carbon fiber, 10 parts of maleic anhydride, stearic acid 1 part of calcium lubricant, 1 part of antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0037] The preparation method is the same as in Example 1.

Embodiment 3

[0039] A reinforced semi-aromatic nylon / liquid crystal polymer alloy material, made of the following raw materials in parts by weight: 60 parts of semi-aromatic nylon PA10T, 5 parts of liquid crystal polymer 5130L, 20 parts of acicular wollastonite, and 5 parts of maleic anhydride , 0.5 parts of calcium stearate lubricant, 0.5 parts of antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0040] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com