Inner wall putty paste and preparation method thereof

A putty paste, interior wall technology, applied in filling slurry and other directions, can solve the problems of paint and wallpaper corrosion, high alkalinity of materials, low adhesion, etc., and achieve dense texture, high adhesion and good flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

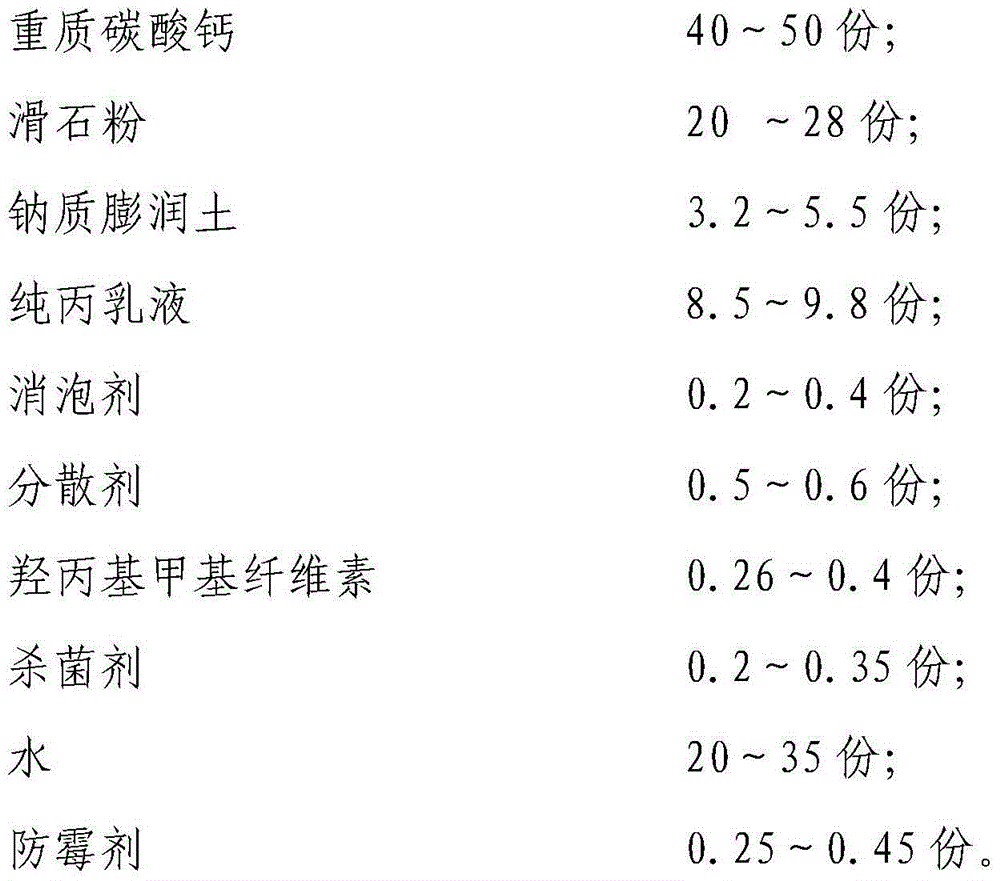

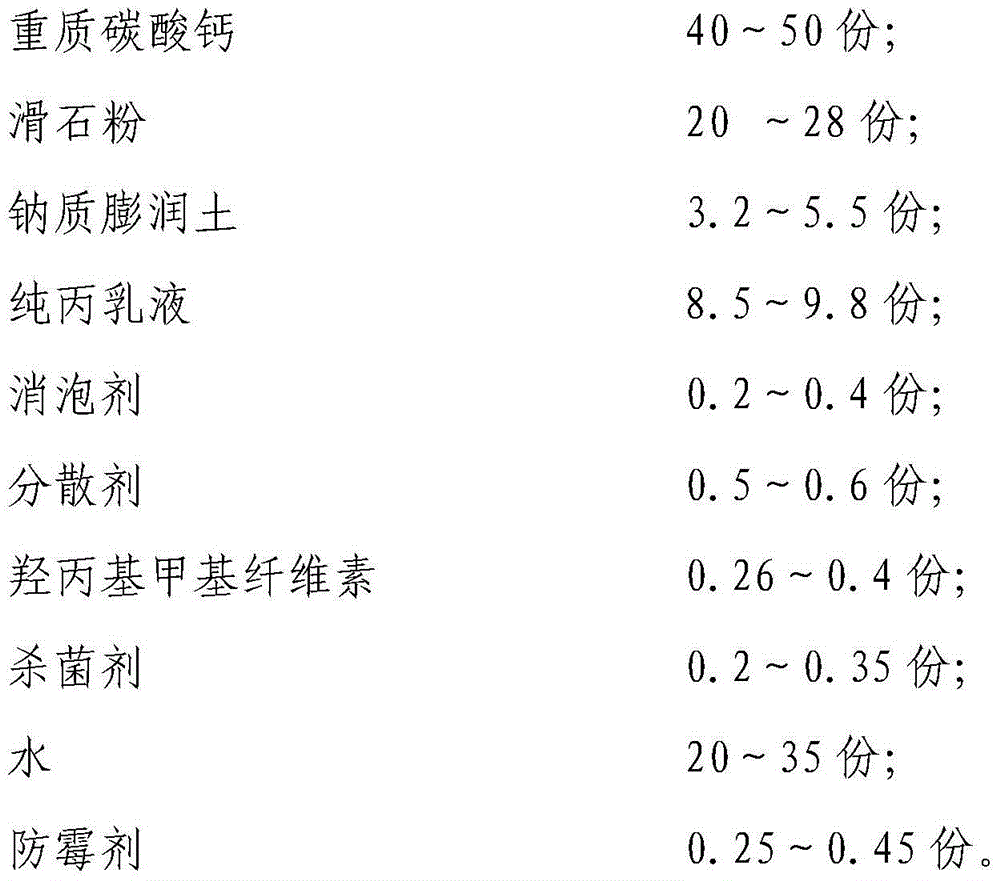

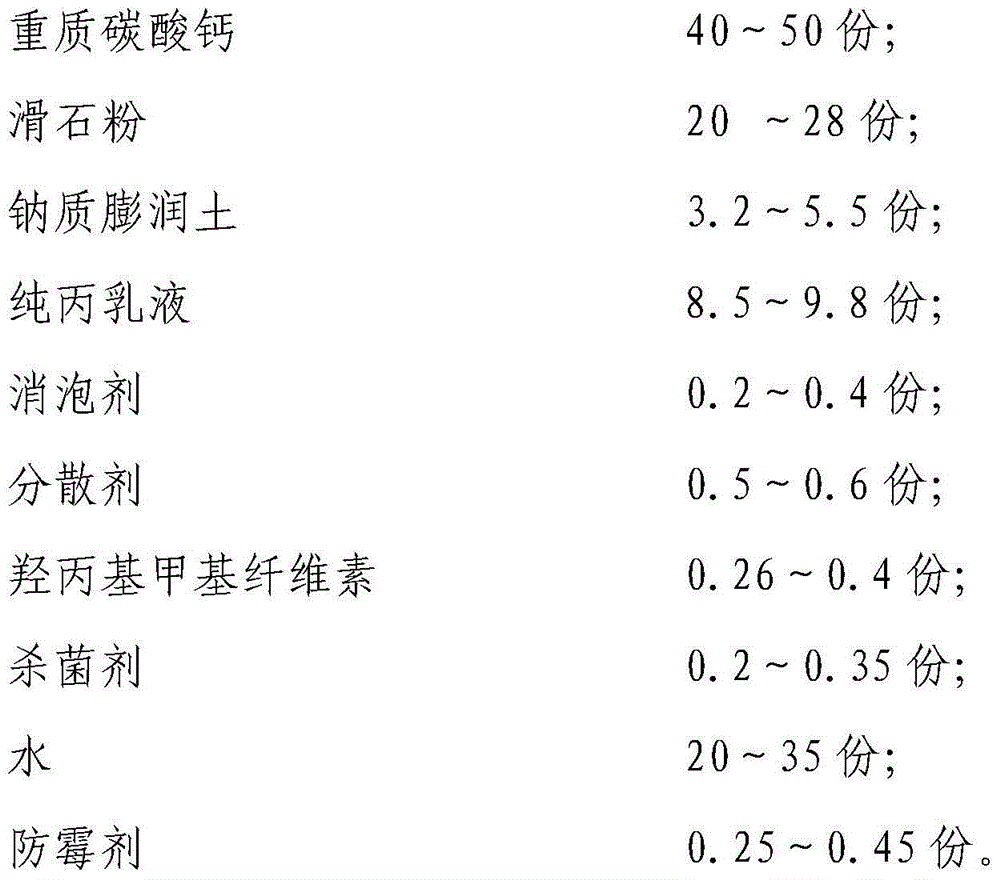

[0020] The putty paste of the present invention is prepared from the following raw materials in parts by weight: 40 parts of heavy calcium carbonate; 20 parts of talcum powder; 3.7 parts of sodium bentonite; 8.8 parts of pure acrylic emulsion; 0.2 parts of defoaming agent; 0.5 parts; 0.26 parts of hydroxypropyl methylcellulose; 0.2 parts of fungicide; 26 parts of water; The preparation method of the putty paste comprises the following steps: respectively adding a bactericide, a dispersant, an antifungal agent, and a defoamer into water, stirring for 5 minutes, then adding heavy calcium carbonate, talcum powder and sodium bentonite, and stirring for 20 minutes, Then add pure acrylic emulsion, stir for 10 minutes, finally add a thickener, stir for another 10 minutes, then carry out canning to obtain the finished product.

Embodiment 2

[0022] The putty paste of the present invention is formulated from the following raw materials in parts by weight: 45 parts of heavy calcium carbonate; 20 parts of talcum powder; 4.2 parts of sodium bentonite; 8.9 parts of pure acrylic emulsion; 0.3 parts of defoaming agent; 0.6 parts; 0.38 parts of hydroxypropyl methylcellulose; 0.2 parts of fungicide; 20 parts of water; The preparation method of the putty paste comprises the following steps: respectively adding a bactericide, a dispersant, an antifungal agent, and a defoamer into water, stirring for 5 minutes, then adding heavy calcium carbonate, talcum powder and sodium bentonite, and stirring for 22 minutes, Then add pure acrylic emulsion, stir for 10 minutes, finally add a thickener, stir for another 10 minutes, then carry out canning to obtain the finished product.

Embodiment 3

[0024] The putty paste of the present invention is formulated from the following raw materials in parts by weight: 45 parts of heavy calcium carbonate; 21 parts of talcum powder; 3.2 parts of sodium bentonite; 8.6 parts of pure acrylic emulsion; 0.4 part of defoamer; 0.6 parts; 0.4 parts of hydroxypropyl methylcellulose; 0.35 parts of fungicide; 20 parts of water; The preparation method of the putty paste comprises the following steps: respectively adding a bactericide, a dispersant, an antifungal agent, and a defoamer into water, stirring for 6 minutes, then adding heavy calcium carbonate, talcum powder and sodium bentonite, and stirring for 22 minutes, Then add pure acrylic emulsion, stir for 10 minutes, finally add a thickener, stir for another 10 minutes, then carry out canning to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com