Low-silver, copper and lanthanum alloy for commutator and preparation method of low-silver, copper and lanthanum alloy

A commutator, silver-copper technology, applied in the field of high-quality copper alloy electrical materials and preparation, to achieve obvious market advantages and reduce material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

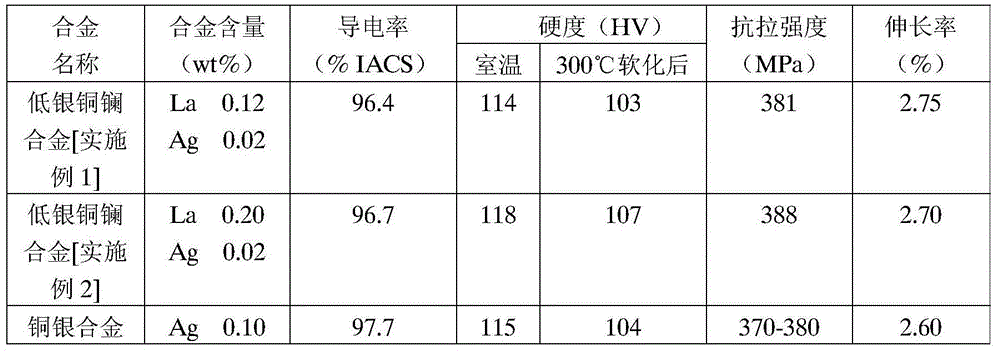

Embodiment 1

[0016] The low-silver copper-lanthanum alloy is configured according to the composition requirements of the present invention. A lanthanum-containing 30% copper-lanthanum master alloy is selected (considering the burnout rate of the master alloy is 10%); the selected cathode copper plate contains 99.95% copper. Weigh 99.58 kg of cathode copper plate, 0.02 kg of pure silver, and 0.45 kg of copper-lanthanum master alloy. When the power frequency induction furnace is heated up to 1140°C-1160°C, 90.18kg of electrolytic copper is added in turn, and pure silver is added after melting, and then 9.40kg of cathode copper plate inlaid with copper-lanthanum master alloy is pressed into the copper liquid; the surface of the copper liquid in the melting zone is Covered with charcoal, the casting area covered with graphite flakes. Repeat this until the liquid level in the furnace meets the requirements, stop feeding, remove slag, keep warm for about 1 hour, start continuous casting, and fe...

Embodiment 2

[0018] The low-silver copper-lanthanum alloy is configured according to the composition requirements of the present invention. A lanthanum-containing 30% copper-lanthanum master alloy is selected (considering the burnout rate of the master alloy is 10%); the selected cathode copper plate contains 99.95% copper. Weigh 99.28kg of cathode copper plate, 0.02kg of pure silver, and 0.74kg of copper-lanthanum master alloy. When the power frequency induction furnace heats up to 1140°C-1180°C, add 89.88kg of electrolytic copper in sequence, add pure silver after melting, and then press 9.40kg of cathode copper plate inlaid with copper-lanthanum master alloy into the copper liquid; the surface of the copper liquid in the melting zone Covered with charcoal, the casting area covered with graphite flakes. Repeat this until the liquid level in the furnace meets the requirements, stop feeding, remove slag, keep warm for about 1 hour, start continuous casting, and feed in time according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com