High-toughness radiation-proof multi-element alloy and preparation method thereof

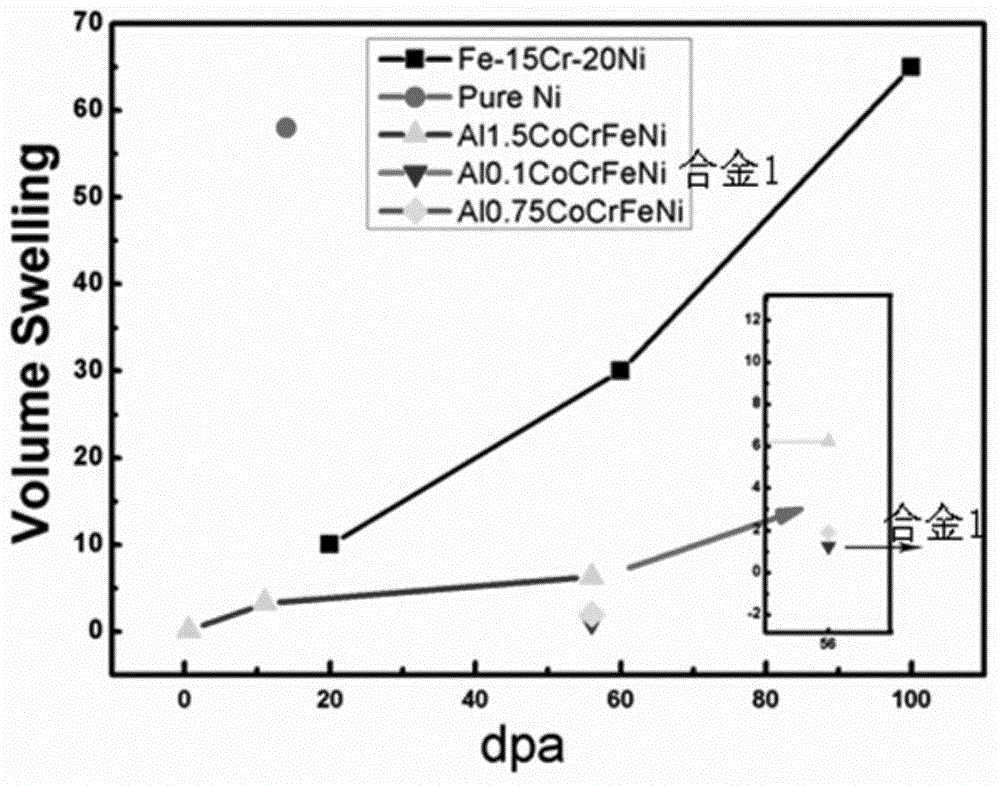

A multi-element, anti-radiation technology, applied in the field of low-temperature environment and anti-radiation environment, can solve the problems of complex operation, small ingot volume, small copper mold suction casting volume, etc., and achieve excellent performance and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. alloy composition: the alloy composition of embodiment is Al 0.1 CoCrFeNi.

[0040] 2. The alloy melting method comprises the following steps:

[0041] Step 1: First design the atomic ratio expression of the alloy composition as Al 0.1 CoCrFeNi, then converted to mass ratio according to the atomic ratio;

[0042] Step 2: use sandpaper and grinder to remove the surface scale of metallurgical raw materials Al, Co, Cr, Fe and Ni with a purity of more than 99.9%, and use industrial ethanol to ultrasonically clean the raw metal, dry, and set aside;

[0043] Step 3: Precisely weigh and proportion the raw materials treated in step 2, with a total mass of 1.5kg to 5kg;

[0044] Step 4: Put the metal raw materials with a total mass of 1.5kg to 5kg into the water-cooled copper crucible from the upper cavity of the vacuum magnetic levitation melting furnace, and place the other raw materials in the cavity preset place;

[0045] Step 5: vacuumize the sample chamber of the va...

Embodiment 2

[0049] 1. alloy composition: the alloy composition of embodiment is Al 0.3 CoCrFeNi.

[0050] 2. The alloy melting method comprises the following steps:

[0051] Step 1: First design the atomic ratio expression of the alloy composition as Al 0.3 CoCrFeNi, then converted to mass ratio according to the atomic ratio;

[0052] Step 2: use sandpaper and grinder to remove the surface oxide scales of metallurgical raw materials Al, Co, Cr, Fe and Ni with a purity of more than 99.9%, and use industrial ethanol to ultrasonically clean the raw metal, dry, and set aside;

[0053] Step 3: Precisely weigh and proportion the raw materials treated in step 2, with a total mass of 1.5kg to 5kg;

[0054] Step 4: Put the metal raw materials with a total mass of 1.5kg to 5kg into the water-cooled copper crucible from the upper cavity of the vacuum magnetic levitation melting furnace, and place the other raw materials in the cavity preset place;

[0055] Step 5: vacuumize the sample chamber of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com