Welding heater

A heater and mixer technology, which is applied in the field of heating devices for preheating and heat preservation or post-weld heat treatment, can solve the problems of inability to meet rapid ignition, affect product welding quality, and high requirements for brackets, and achieve fast ignition speed and combustion. Process stability and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

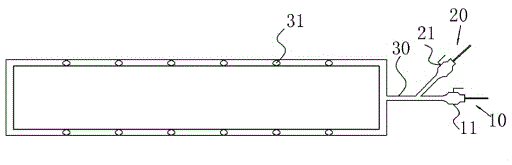

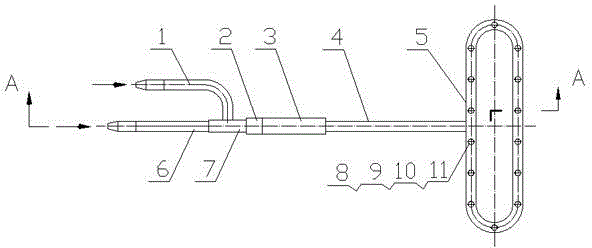

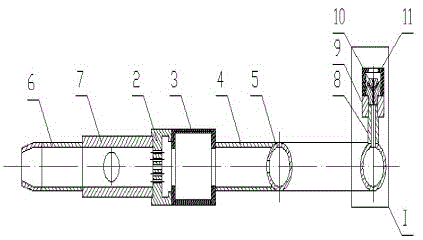

[0033] One of the specific implementations of a welding heater of the present application, see figure 2 and Figure 5 As shown, its structure includes a mixed gas inlet pipe, an annular fire ring 5 and several burner assemblies, and the annular fire ring 5 is connected to the mixed gas inlet pipe and communicated with the mixed gas inlet pipe , the center line of the annular fire ring 5 along the length direction is perpendicular to the air intake direction of the mixed gas intake pipe, and the annular fire ring 5 is provided with the plurality of nozzles along the annular fire ring 5 The component corresponds to the mixed gas vent hole, and the burner assembly is arranged in the mixed gas vent hole.

[0034] Compressed air and gas enter the mixed gas intake pipe side by side for mixing, and then enter the annular fire ring 5 for diversion, then ignite above the burner 10, adjust the flow of the two gases and adjust the size of the flame to start preheating, heat preservatio...

Embodiment 2

[0043] The second embodiment of a welding heater of the present application, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment shall be explained in embodiment 1, and shall not be repeated here to repeat. The difference between this embodiment and embodiment 1 is that, see figure 2 and Figure 5 As shown, the annular fire ring 5 can be an oblong annular fire ring 5, the length and width of the oblong annular fire ring 5 are determined according to the thickness of the structure to be heated, generally speaking, the length is about 500mm to 800mm, the width is 2 to 3 times the thickness of the heated structure. Since the positions of the four corners of the oblong annular fire ring 5 are arc-shaped transitions, the mixture gas inside is smoothly transitioned without affecting the flow rate of the mixture gas, so that the combustion is stable.

[0044] see Figure 7 As shown, the annular fir...

Embodiment 3

[0047] The third specific embodiment of a welding heater of the present application, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment shall adopt the explanation in embodiment 1, and shall not be repeated here to repeat. The difference between this embodiment and embodiment 1 is that, see Figure 6 As shown, the annular fire ring 5 is a single annular fire ring 5 or an annular fire ring 5 with an 8-shaped structure composed of two annular fire rings 5 . In a technical solution, the mixed gas inlet pipes can be set in two groups, which are respectively located on the left and right sides of a single annular fire ring 5 or an 8-shaped annular fire ring 5, and the mixed gas pipes on both sides are simultaneously connected to the Compressed air and gas. In another technical solution, the mixed gas intake pipes are only arranged in one group, and communicated through the connection mode of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com