Coaxial digital holographic microscopy imaging device and method for detecting glass subsurface defect

A digital holographic microscope and imaging device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inaccurate estimation, difficult resolution and inspection of sub-surface defects, etc., and achieve high adaptability, simple structure and high performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

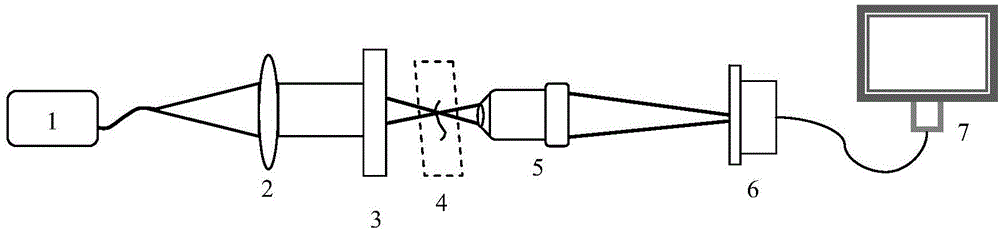

[0024] The He-Ne laser 1 emission wavelength described in the present embodiment is the monochromatic light of 632.8nm; Sample 3 is the glass that has subsurface damage, and damage size is micron or submicron order of magnitude; The numerical aperture of microscopic objective lens 5 is 0.55; the charge coupler 6 is an area coupler.

[0025] The present invention is based on the coaxial digital holographic microscopic imaging device and the method for detecting glass subsurface defects, including the following steps:

[0026] Step 1, He-Ne laser 1 emits monochromatic light with a wavelength of 632.8nm, irradiates on the collimating objective lens 2, and adjusts the collimating objective lens 2 so that the emitted light hits the sample 3 evenly on the glass with subsurface defects;

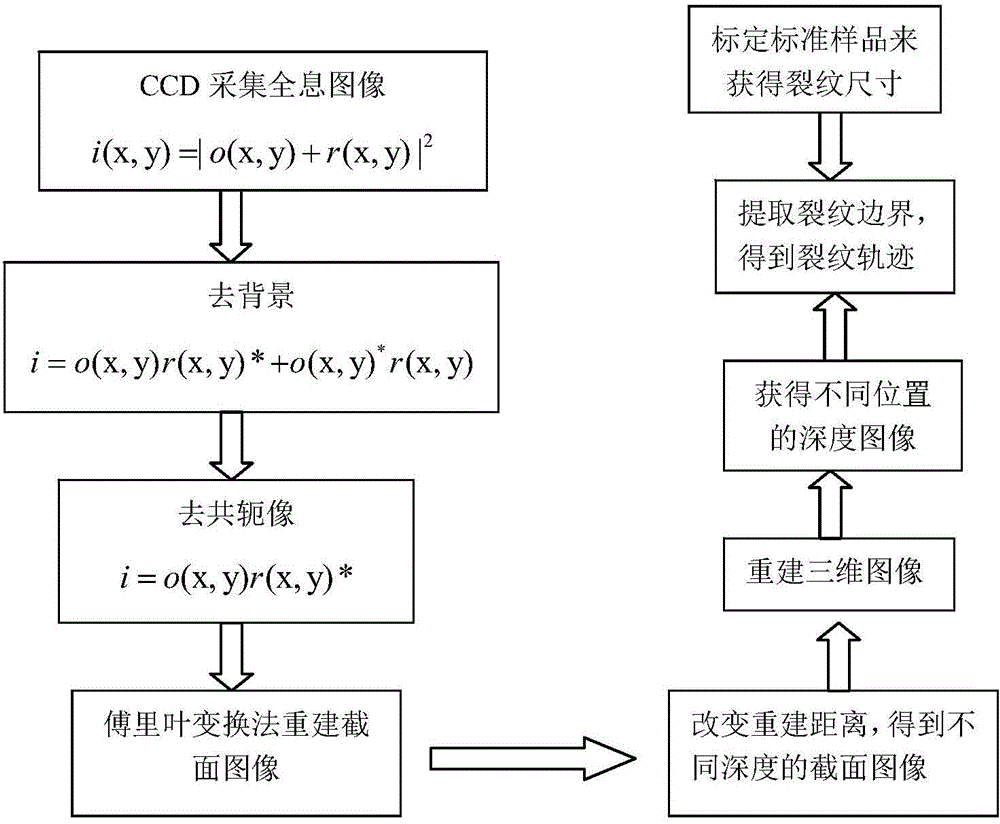

[0027] Step 2, transmit the light beam of the sample 3, part of the light is scattered by the sample as the sample light, and the other part is not scattered as the reference light, and the two ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com