Metal/graphene composite material and preparation method as well as application thereof

A composite material, graphene technology, applied in the direction of metal/alloy conductors, cable/conductor manufacturing, electrical components, etc., can solve the problems of brittle composite materials, poor bonding strength, cumbersome process, etc., to achieve good conductivity and high bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing the metal / graphene composite material described in the above technical scheme, comprising the following steps:

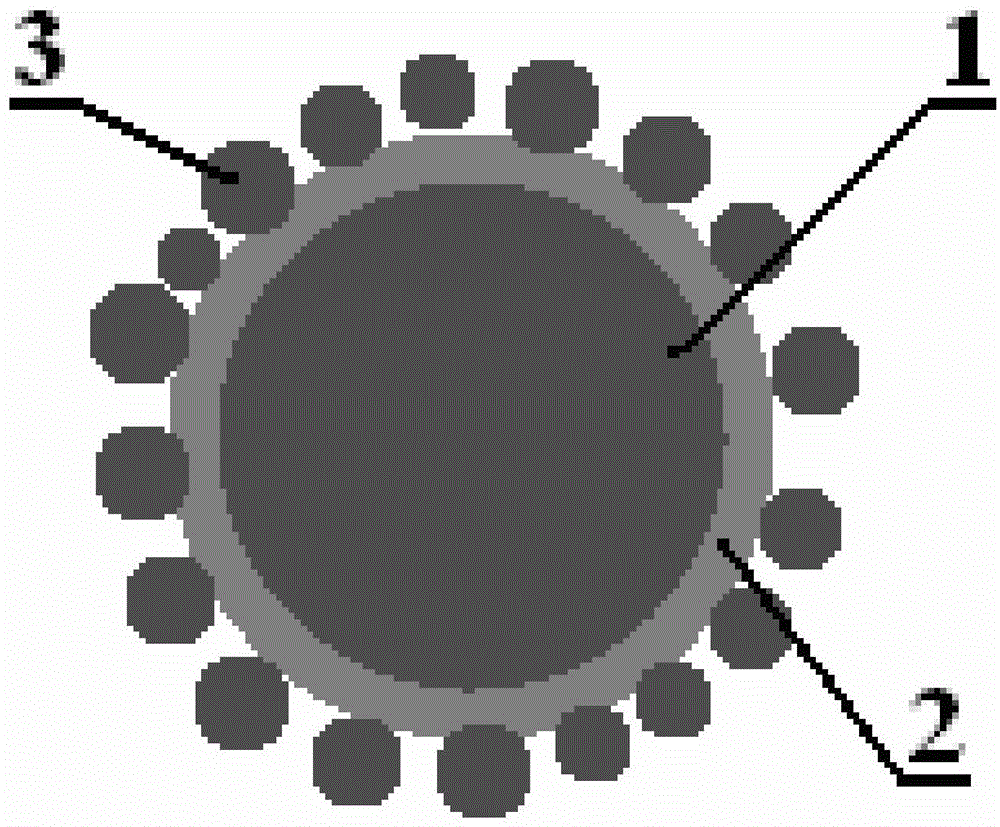

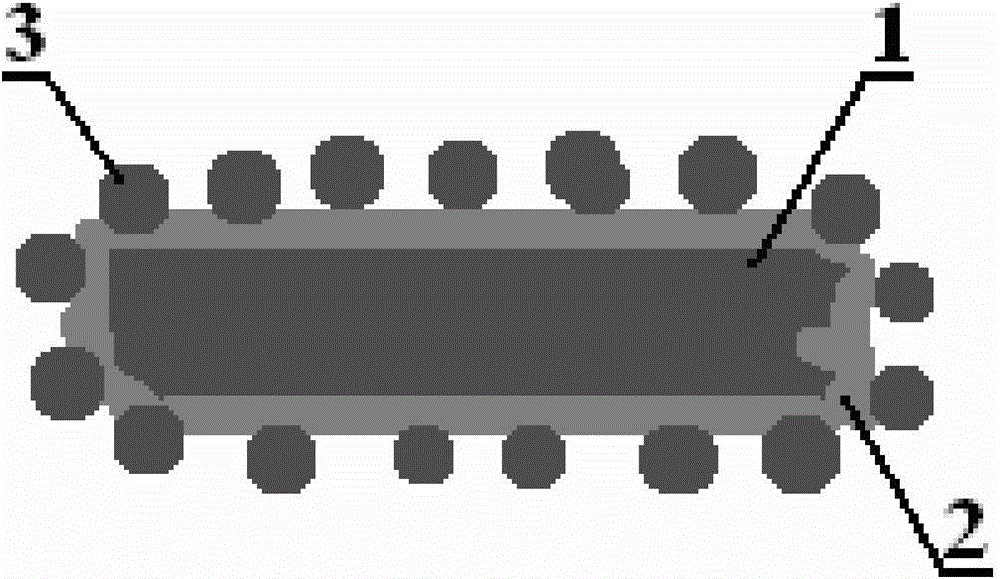

[0043] a) mixing the surface-treated micron-sized metal powder with graphene-based raw materials, annealing, and obtaining metal powder wrapped with graphene-based raw materials;

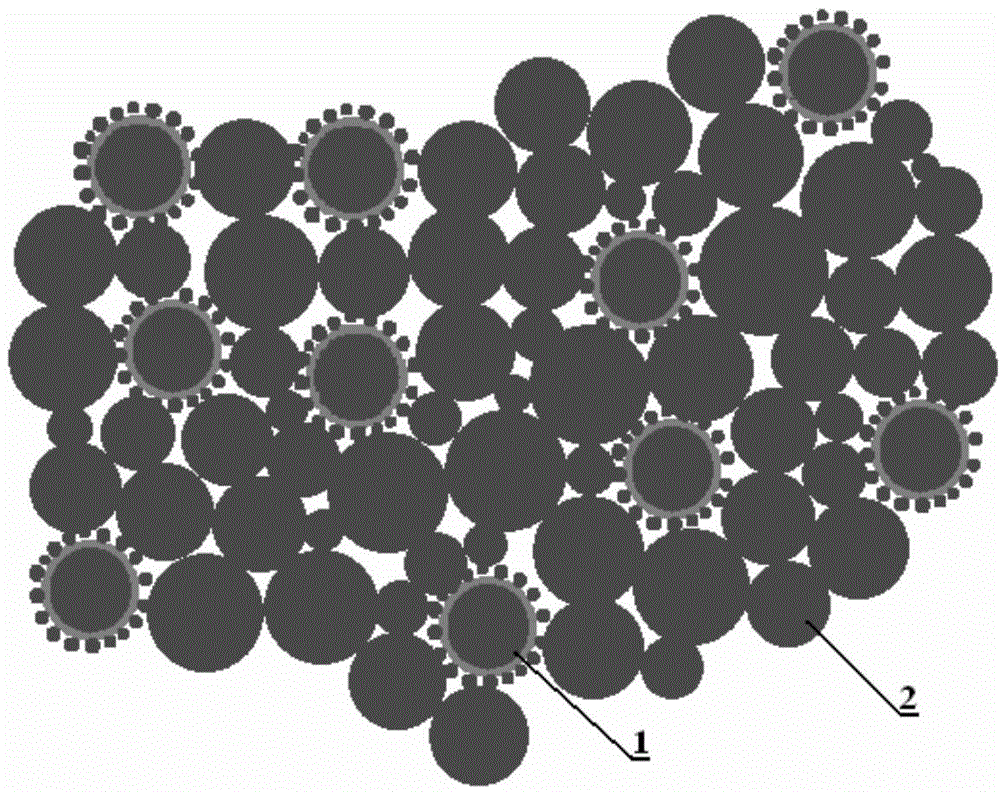

[0044] b) mixing the above metal powder wrapped with graphene-based raw materials with a reducing agent in a metal salt solution, and performing an oxidation-reduction reaction to obtain a metal / graphene composite material.

[0045]In the present invention, the surface-treated micron-sized metal powder is mixed with graphene-based raw materials, and annealed to obtain copper powder wrapped with graphene-based raw materials. In the present invention, the graphene-based raw material is graphene or graphene oxide; the present invention has no special restrictions on the source of the graphene-based raw material, and adopts com...

Embodiment 1

[0078] (1) After mixing 100g of spherical micron-sized copper powder with an average particle size of 1.8μm and 30g of silane coupling agent evenly, then filter and wash to obtain surface-treated micron-sized copper powder, and then surface-treated micron-sized copper powder Disperse copper powder in 100g of water, stir until uniformly dispersed, and obtain solution A; at the same time, add 1g of graphene to solution A, stir ultrasonically for 5min under the condition of 1200W power, filter, wash and dry to obtain a solid powder, and then dissolve the solid powder Raise the temperature to 250°C at a heating rate of 10°C / min for 2 hours, then raise the temperature to 650°C at a heating rate of 10°C / min for 2 hours, and finally perform annealing treatment to obtain graphene-coated copper powder.

[0079] (2) Add 10.5g of the above-mentioned graphene-wrapped copper powder to 300mL of copper sulfate solution containing 5g, then add 1.5g of hydrazine hydrate, and react at 85°C for 2...

Embodiment 2

[0083] (1) Mix 100g of flaky micron-sized copper powder with an average particle size of 5μm and 50g of silane coupling agent evenly, then filter and wash to obtain surface-treated micron-sized copper powder, and then surface-treated micron-sized copper powder Copper powder is dispersed in 150g of water, stirred until uniformly dispersed, and solution A is obtained; at the same time, 0.5g of graphene oxide or graphene is added to solution A, and ultrasonically stirred for 10min under the condition of 1200W power, suction filtered, washed and dried to obtain Solid powder, then the solid powder is heated to 250°C at a heating rate of 10°C / min and kept for 2h, then raised to 650°C at a heating rate of 10°C / min and kept for 2h, and finally annealed to obtain graphene-coated copper pink.

[0084] (2) Add 10.05g of the above-mentioned graphene-wrapped copper powder to 300mL of copper sulfate solution containing 2.5g, then add 0.7g of hydrazine hydrate, and react at 85°C for 2h to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com