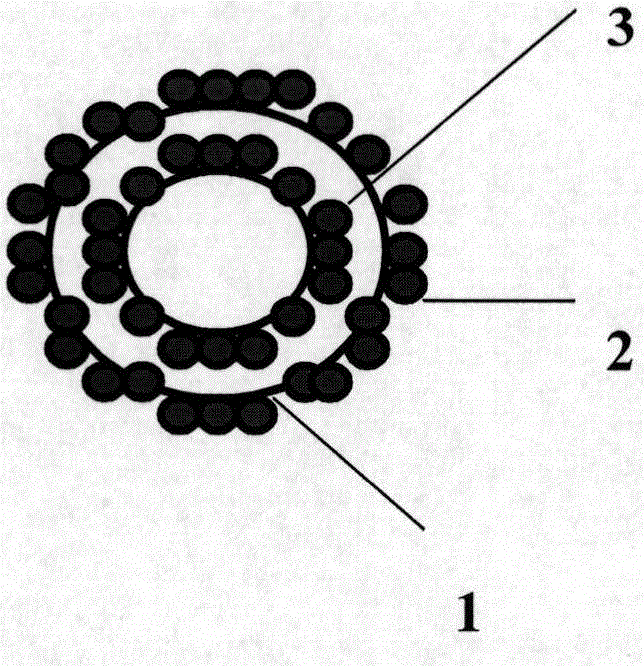

Preparation method of polyaniline/sulfur composite material with hollow core-shell structure

A composite material, core-shell structure technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problem of no improvement in cycle life and rate performance, and achieve the effect of being conducive to industrial production, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A polyaniline / sulfur composite material with a hollow core-shell structure; polyaniline / sulfur is a single-layer structure, and the composition is designed as follows:

[0028] Sulfur, 80wt%; Polyaniline 20wt%;

[0029] The preparation of polyaniline / sulfur composites includes the following steps:

[0030] 1) Weigh 0.4g of silicon dioxide, pour it into an alcohol solution containing 0.2g of aniline, and ultrasonically disperse for 5 hours; wherein, the particle size of silicon dioxide is 10nm;

[0031] 2) In the product of step 1, an initiator is added, aniline is polymerized and coated with silica; centrifuged and dried to obtain a polyaniline / silica composite material;

[0032] 3) Immerse the product of step 2 in a sufficient amount of sulfur / carbon disulfide saturated solution; filter and dry; repeat step 3 for immersion, filtration, and drying operations 2 to 10 times to obtain a sulfur / polyaniline / silicon dioxide composite material;

[0033] 4) Immerse the produc...

Embodiment 2

[0036] A sulfur / polyaniline composite material with a hollow core-shell structure; polyaniline / sulfur / polyaniline / sulfur / polyaniline is a three-layer structure, and the composition is designed as follows:

[0037] Sulfur, 76wt%; Polyaniline 24wt%;

[0038] The preparation of polyaniline / sulfur composites includes the following steps:

[0039] 1) Weigh 0.4g of silicon dioxide, pour it into an alcohol solution containing 0.08g of aniline, and ultrasonically disperse for 6 hours; wherein, the particle size of silicon dioxide is 10nm;

[0040] 2) In the product of step 1, an initiator is added, aniline is polymerized and coated with silica; centrifuged and dried to obtain a polyaniline / silica composite material;

[0041] 3) Immerse the product of step 2 in a sufficient amount of sulfur / carbon disulfide saturated solution; filter and dry; repeat step 3 for immersion, filtration, and drying operations 2 to 10 times to obtain a sulfur / polyaniline / silicon dioxide composite material; ...

Embodiment 3

[0047] A sulfur / polyaniline composite material with a hollow core-shell structure; sulfur / polyaniline / sulfur / polyaniline / sulfur / polyaniline is a three-layer structure, and the composition is designed as follows:

[0048] Sulfur, 70wt%; Polyaniline 30wt%;

[0049] The preparation of polyaniline / sulfur composites includes the following steps:

[0050] 1) Weigh 0.4g of silicon dioxide, pour into an alcohol solution containing 0.1g of aniline, and ultrasonically disperse for 4 hours; wherein, the particle size of silicon dioxide is 10nm;

[0051] 2) In the product of step 1, an initiator is added, aniline is polymerized and coated with silica; centrifuged and dried to obtain a polyaniline / silica composite material;

[0052] 3) Immerse the product of step 2 in a sufficient amount of sulfur / carbon disulfide saturated solution; filter and dry; repeat step 3 for immersion, filtration, and drying operations 2 to 10 times to obtain a sulfur / polyaniline / silicon dioxide composite materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com