Low-temperature rapid heating method and system for power battery pack for electric vehicle

A power battery pack and rapid heating technology, applied in electric vehicles, secondary batteries, electric traction, etc., can solve problems such as difficulty in ensuring heat uniformity, increased temperature difference of battery modules, and slow heating speed, etc., to achieve heating Fast speed, improved heating efficiency, and short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

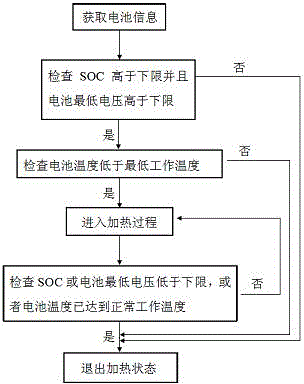

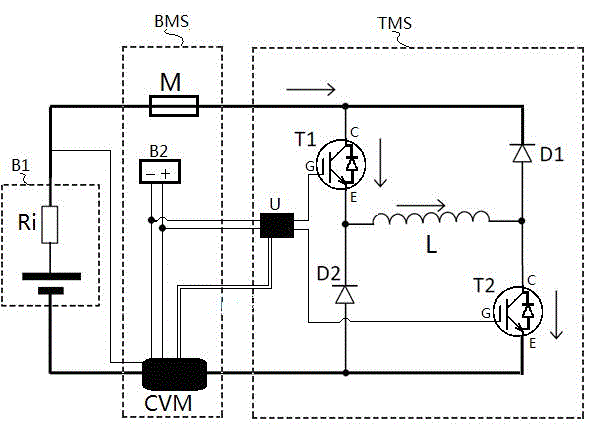

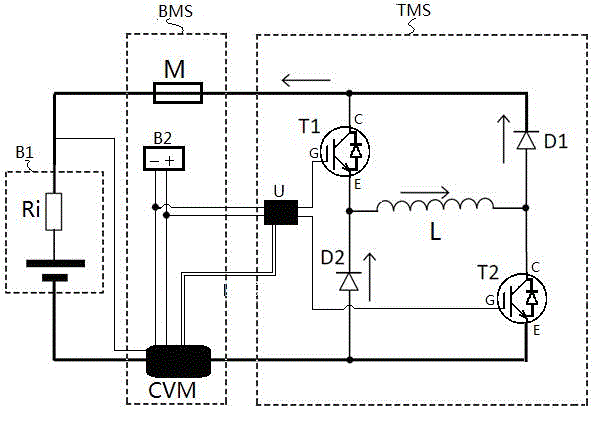

[0020] The low-temperature rapid heating method of the electric vehicle power battery pack in the embodiment of the present invention adopts the method of instantaneous short circuit, and the instantaneous short circuit time is t, a large short-circuit current I is generated in the system, and a value is generated on the internal resistance Ri of the power battery pack for W=I 2 ×Ri×t heat, the heat evenly occurs inside each battery module of the power battery pack B1; a momentary short circuit generates a large current, and then heats up the power battery pack B1 through the internal resistance Ri of the battery pack itself. Since the power battery pack B1 is composed of battery modules in series, each battery module can be heated evenly, and the heat is generated inside the battery and diffused from the inside to the outside, thereby achieving rapi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com