Heat pump units, air conditioners and refrigerators

A heat pump device and motor technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as the inability to use sensorless vector control, and achieve the effect of suppressing cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

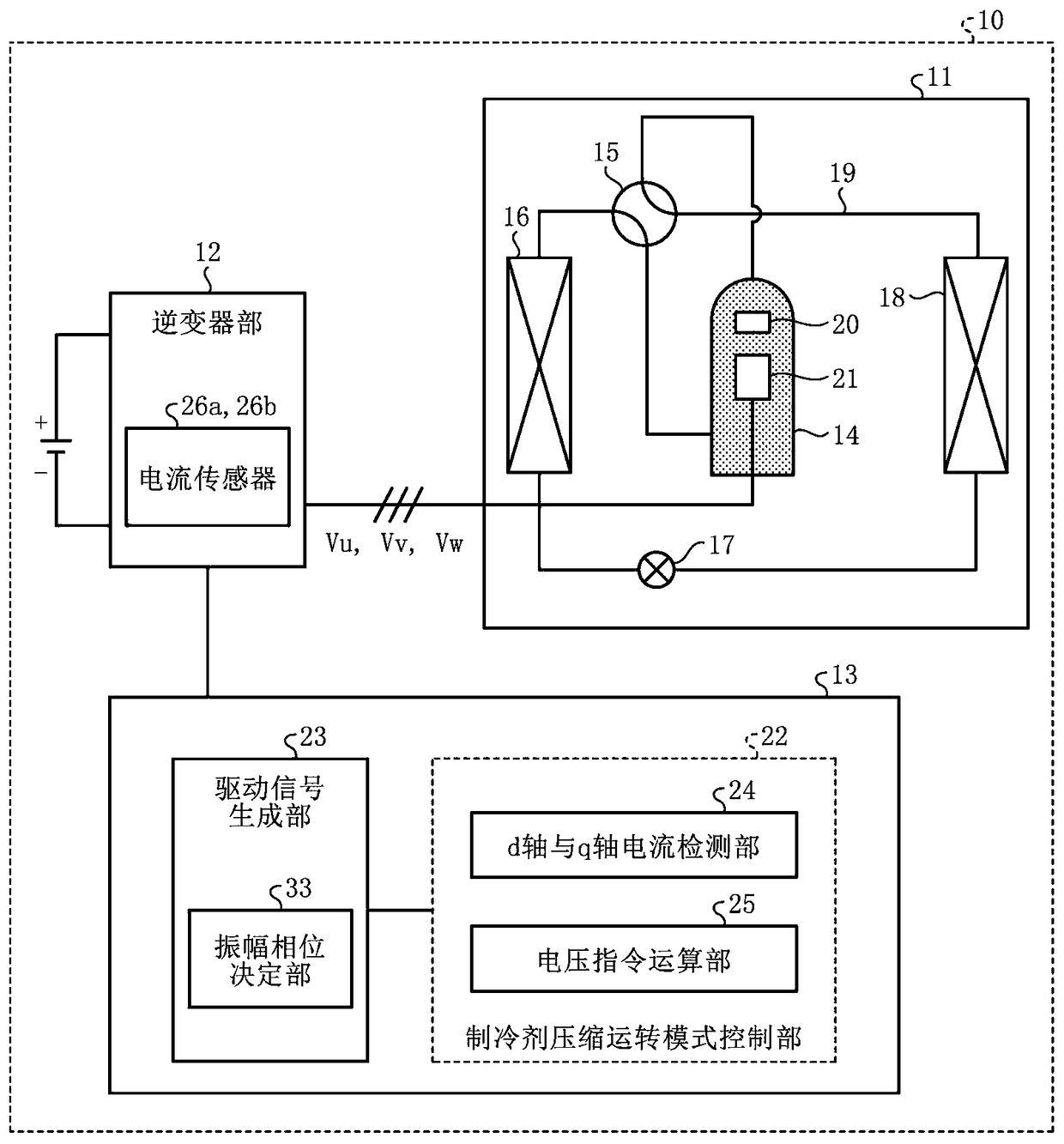

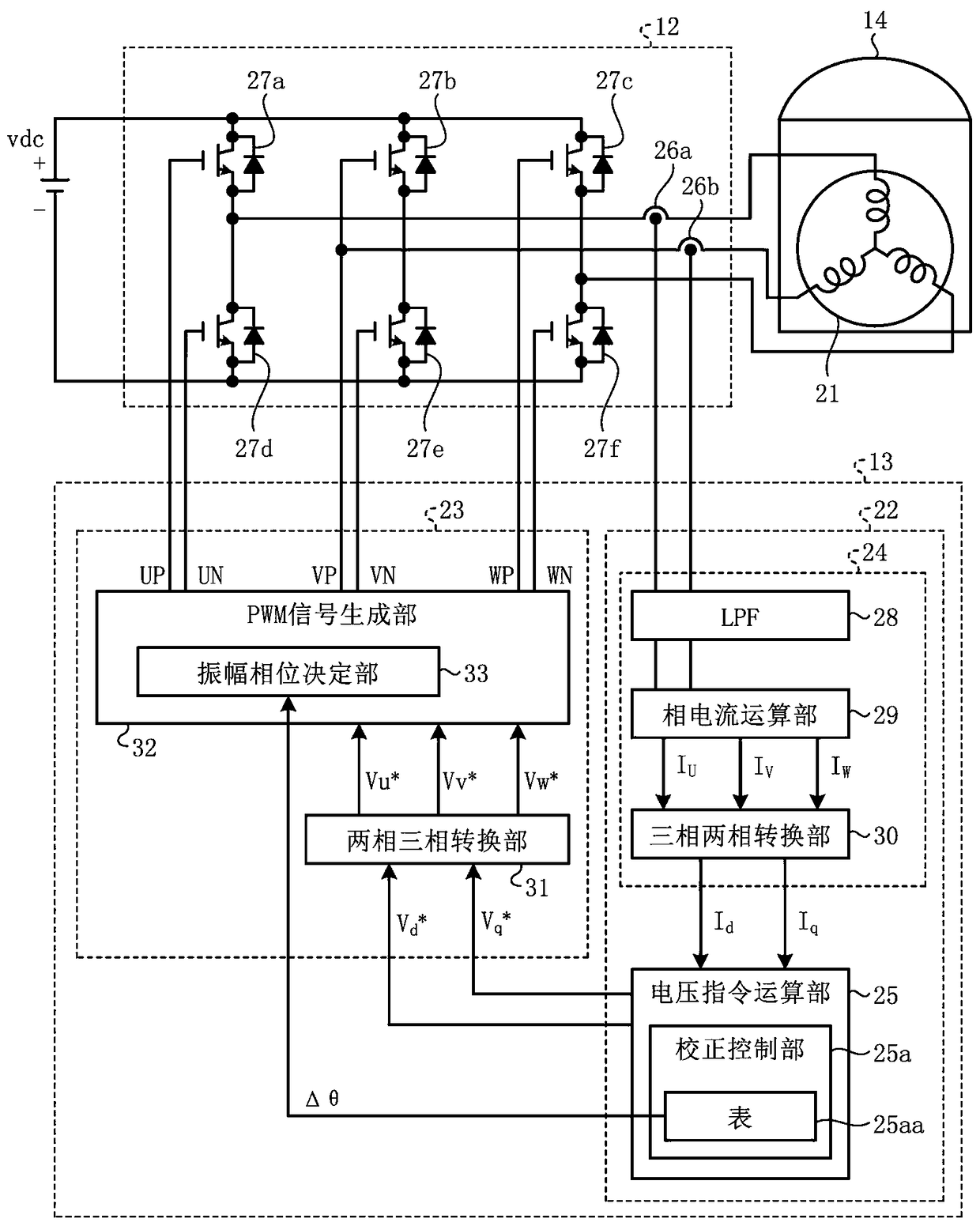

[0029] In this embodiment, refer to Figure 1 to Figure 6 The structure and operation of the heat pump device of the present invention will be described.

[0030] figure 1 It is a figure which shows the heat pump apparatus 10 which is one structural example of the heat pump apparatus of this embodiment. figure 1 The illustrated heat pump device 10 includes a refrigeration cycle unit 11 , an inverter unit 12 , and an inverter control unit 13 . The heat pump device 10 is applied to, for example, an air conditioner or a refrigerator.

[0031] The refrigeration cycle unit 11 includes a compressor 14 , a four-way valve 15 , a heat exchanger 16 , an expansion mechanism 17 , and a heat exchanger 18 , and these are connected by a refrigerant pipe 19 .

[0032] The compressor 14 includes a compression mechanism 20 and a motor 21 inside. The compression mechanism 20 compresses the refrigerant. The motor 21 is a three-phase motor having three-phase windings of U-phase, V-phase, and ...

Embodiment approach 2

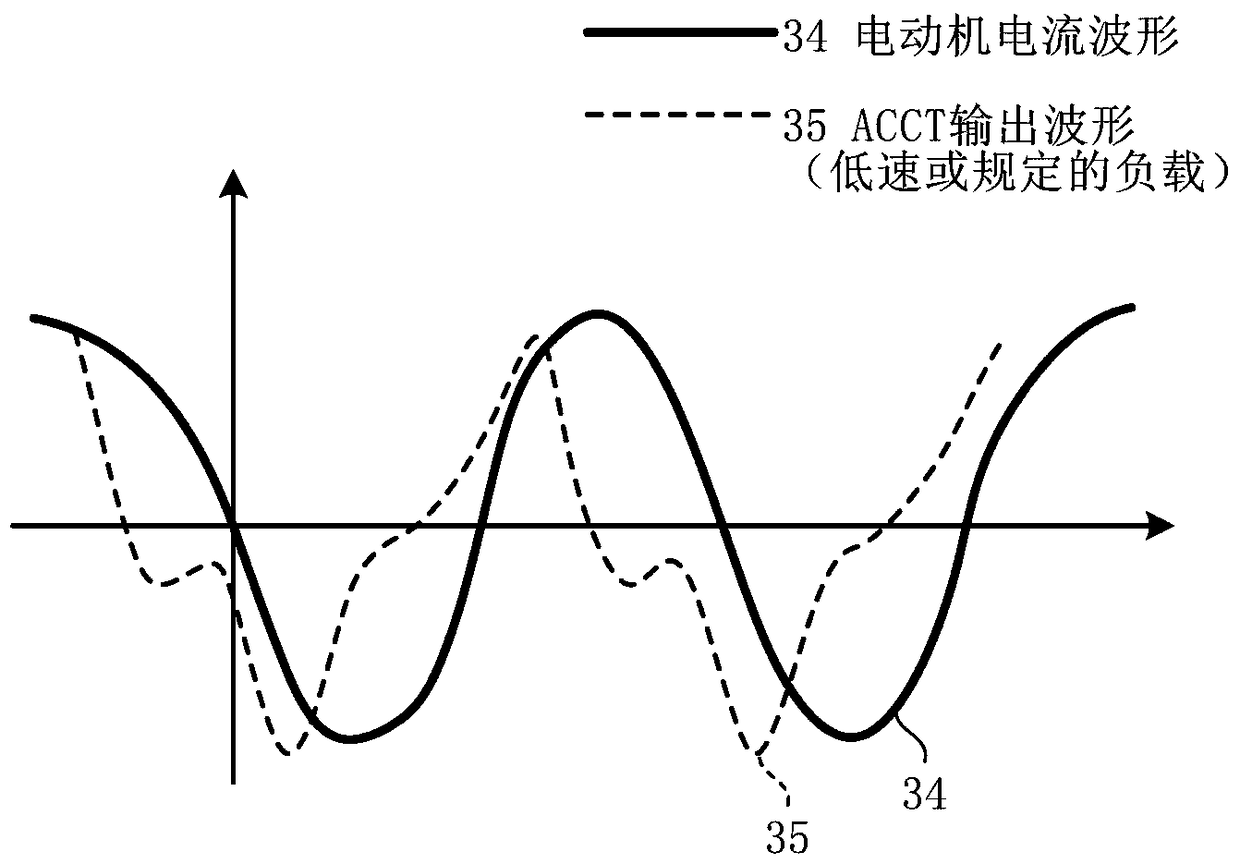

[0062] The heat pump device of the present invention was described in Embodiment 1, and in this embodiment, refer to Figure 7 with Figure 8 The current sensor (current sensor 26a and current sensor 26b in Embodiment 1) included in the heat pump device of the present invention will be described.

[0063] Figure 7 It is a diagram showing a configuration example of the current sensor 26a and the current sensor 26b when a low-resistance resistance element (for example, 10Ω) is used for the ACCT secondary-side (output-side) resistor 43 included in the heat pump device 10 .

[0064] The output voltage is low when the resistance value of the secondary side resistor 43 of ACCT is low. Thus, in Figure 7 In the shown configuration example, an amplifier 44 is provided at the secondary-side output post-stage to amplify a voltage that can be input to a microcomputer 45 . However, in Figure 7 In the configuration example shown, the cost increases due to the amplifier 44, and the o...

Embodiment approach 3

[0075] In this embodiment, a preferred form of the heat pump device 10 of the present invention will be described. In this embodiment, the switching elements 27a to 27f ( figure 2 ) using a wide bandgap semiconductor.

[0076] By using a wide bandgap semiconductor for the switching elements 27a to 27f, the element loss of the switching elements 27a to 27f can be reduced and the current can be increased. Therefore, compared with the case where the wide bandgap semiconductor is not used, the heat sink can be miniaturized or eliminated.

[0077] In addition, examples of wide bandgap semiconductors that can be used in this embodiment include silicon carbide (silicon carbide, also referred to as SiC), diamond, and gallium nitride-based materials (materials containing gallium nitride as a main component).

[0078] Figure 9 It is a graph showing the relationship between the withstand voltage and on-resistance of a silicon element (Si element) and a silicon carbide element (SiC e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com