Vehicle-mounted composite power supply regenerative braking energy recovery system and method

A regenerative braking and energy recovery technology, applied in electric braking systems, power management, electric vehicles, etc., can solve problems such as hidden dangers of vehicle energy supply system safety, complex control of four MOS tubes, energy loss of power devices, etc. Extend the cruising range of the vehicle, the structure and control are simple and easy to operate, and the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

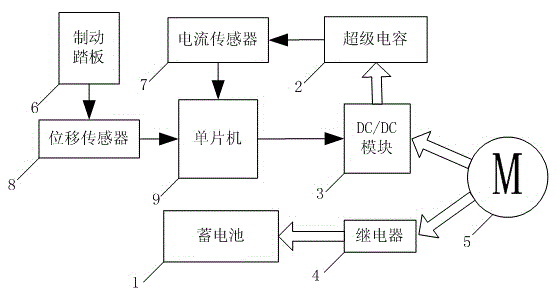

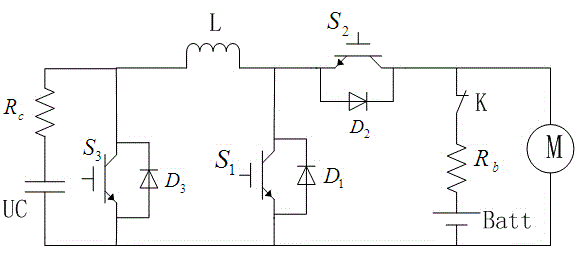

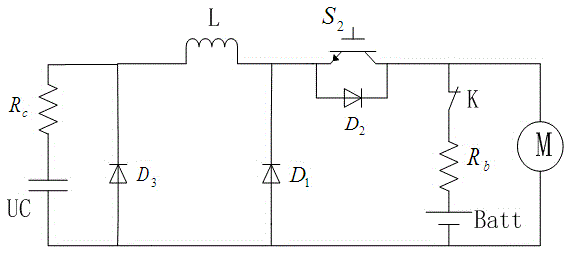

[0020] A vehicle-mounted composite power supply regenerative braking energy recovery system provided by the present invention is as follows: figure 1 As shown, including: storage battery 1, supercapacitor 2, bidirectional DC / DC converter 3 (ie figure 1 DC / DC module in), relay 4, permanent magnet brushed DC motor 5, displacement sensor 8 and single-chip microcomputer 9. The output terminals of the permanent magnet brushed DC motor 5 are respectively connected to the bidirectional DC / DC converter 3 and the relay 4, the supercapacitor 2 and the bidirectional DC / DC converter 3 are connected in series to form an auxiliary energy source, and the battery 1 and the relay 4 are connected in series to form the main energy source , the main energy source and the auxiliary energy source are connected in parallel at the output end of the permanent magnet brushed DC motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com