A kind of preparation method of zeolite

A technology of zeolite and symbiotic zeolite, applied in chemical instruments and methods, crystalline aluminosilicate zeolite, aluminum silicate, etc., can solve the problems of large-scale production difficulty, low product LCC, high product cost, etc., and achieve microscopic appearance The effect of richness, high thermal stability, and low SiO2 content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

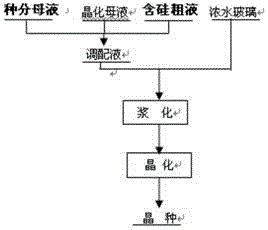

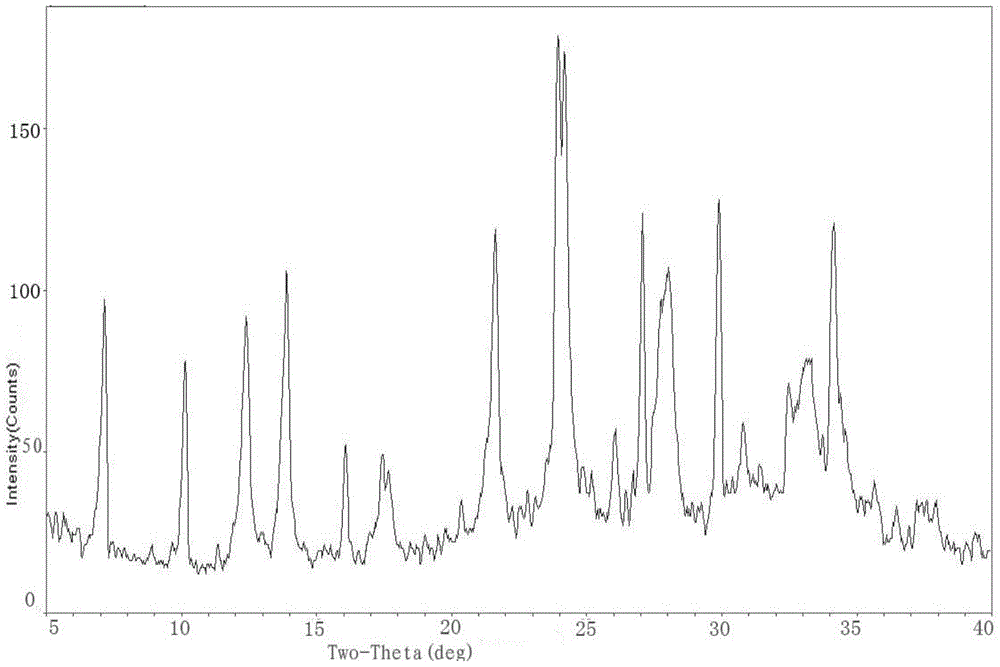

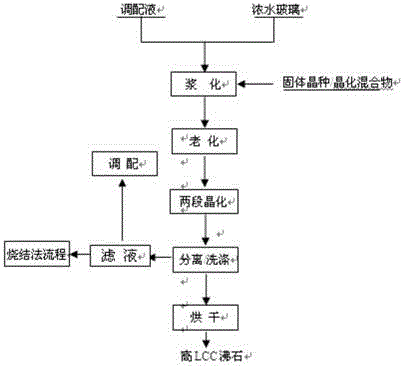

[0029] see Figure 1-4 , a method for preparing zeolite provided by the embodiments of the present invention, comprising:

[0030] Step 110: Obtain water glass and sodium aluminate solution to prepare seed crystals, and the ratio of the preparation system of the seed crystals is Na 2 O: SiO 2 :Al 2 o 3 :H 2 O=(1.0-5.0):(3.0-5.0):1:(50-240);

[0031] Specifically, the step 110 includes obtaining water glass and sodium aluminate solution to prepare seed crystals, and the ratio of the preparation system of the seed crystals is Na 2 O: SiO 2 :Al 2 o 3 :H 2 O=(1.0-5.0):(3.0-5.0):1:(50-240). The reaction temperature of the seed crystal preparation system using water glass and sodium aluminate solution is 70-120°C, preferably 80-100°C; the reaction time is 2-10h, preferably 4-8h.

[0032] Step 120: preparing the required preparation solution;

[0033] Specifically, the step 120 includes preparing the required preparation solution. The prepared preparation liquid includes...

Embodiment 1

[0048] (1) Seed crystal preparation: The synthetic molar ratio is as follows: 3.0Na 2 O 4.0 SiO 2 ·Al 2 o 3 ·90H 2 O. The crystallization temperature is 95°C, and the time is 6 hours; after the crystallization is completed, the crystallization mixture is suction-filtered and washed, and the filter cake is transferred to an oven for blast drying to obtain powdery seed crystals;

[0049] (2) The sintering alumina crude liquor and the crystallization mother liquor are prepared in a volume ratio of 4:3 as the aluminum source. Its chemical composition is: Al 2 o 3 =68.6g / L,Na 2 O=76g / L, αk=1.79; initial temperature 65°C.

[0050] (3) Put 110 ml of industrial concentrated water glass (26.6%, d=1.37) into a reaction vessel and heat it to 55° C. in advance. With the aid of stirring, slowly add 446ml of the preparation solution prepared in step (2) into the reactor, and at the same time add 6.75g of seed crystals, stir rapidly for 15min, and stir the slurry material evenly;

...

Embodiment 2

[0054] (1) seed crystal preparation: with embodiment 1;

[0055] (2) The sintering alumina crude liquor and the crystallization mother liquor are prepared in a volume ratio of 4:3 as the aluminum source. Its chemical composition is: Al 2 o 3 =68.6g / L,Na 2 O=76g / L, αk=1.79; initial temperature 65°C.

[0056] (3) Take 120ml of industrial concentrated water glass (26.6%, d=1.37) and put it into a reaction vessel, and heat it to 55° C. in advance. With the aid of stirring, slowly add 446ml of the preparation solution prepared in step (2) into the reactor, and at the same time add 8.2g of seed crystals, stir rapidly for 15min, and stir the slurry material evenly;

[0057] (4) Raise the temperature of the reactor to 65°C and age for 0.5h;

[0058](5) The temperature of the aged precursor was raised to 75°C for the first-stage crystallization, the crystallization time was 3h; the second-stage crystallization: 95°C, 5h; the stirring speed during the crystallization process was 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com