Method for preparing cluster-type aluminum matrix composites from recycled SICP/AL composites

A technology of aluminum-based composite materials and composite materials, which is applied in the field of preparation, can solve the problems of SiCp/Al composite materials such as difficulty in recycling and poor plastic toughness, and achieve easy microstructure design, high density, and low raw material cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

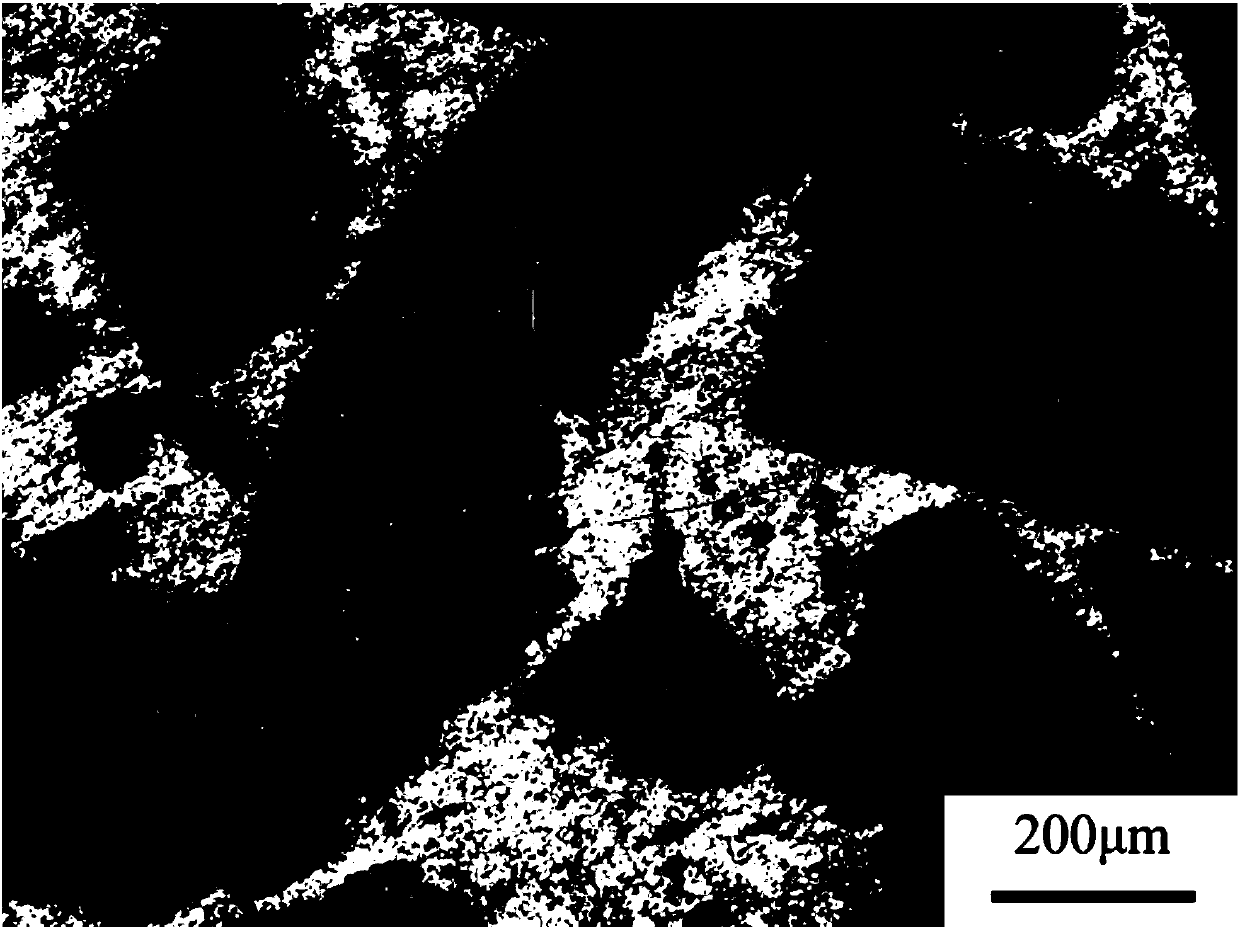

Image

Examples

specific Embodiment approach 1

[0033] Specific implementation mode 1: In this implementation mode, the method for preparing cluster-type aluminum-based composite materials using recovered SiCp / Al composite materials is carried out according to the following steps:

[0034] 1. Pretreatment of composite material waste:

[0035] The composite material waste is crushed to obtain composite material waste particles, and the composite material waste particles are ultrasonically cleaned with a surface detergent, and then the composite material waste particles are ultrasonically cleaned with alcohol, and then the cleaned composite material waste particles are sent into the The drying box is used for drying treatment, and after the drying treatment, mechanical sieving is used to obtain composite material waste powder;

[0036] The composite material waste is SiCp / Al composite material waste, wherein the volume fraction of SiCp in the SiCp / Al composite material is 30vol.%-70vol.%;

[0037] 2. Preparation of prefabric...

specific Embodiment approach 2

[0050] Embodiment 2: This embodiment differs from Embodiment 1 in that: the particle size of the composite material waste powder in step 1 is 300 μm-700 μm. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0051] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, when using surface detergent and alcohol for ultrasonic cleaning, the ultrasonic power is 200-400W, and the ultrasonic cleaning time is 1-10min. . Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com