Porous nio/ceo 2 Hybrid nanosheet array and preparation method and use thereof

A nanosheet array and nanosheet technology, applied in the field of porous NiO/CeO2 hybrid nanosheet array and its preparation, to achieve the effect of large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. NiO / CeO 2 Preparation of Nanosheet Array Precursor

[0021] (1) Place nickel foam (2cm*3cm) purchased from the market into 3mol / L hydrochloric acid and ultrasonically clean it for 30 minutes to remove the oxide layer on the surface, then use deionized water and absolute ethanol to clean it alternately;

[0022] (2) Dissolve 0.152g of cerium nitrate, 0.026g of ammonium fluoride and 0.1051g of urea in 35mL of distilled water to form a mixed solution and transfer it to an autoclave;

[0023] (3) Place the nickel foam obtained in step 1 in an autoclave containing the mixed solution obtained in step 2, seal it and carry out hydrothermal treatment in an oven at 120° C. for 12 hours;

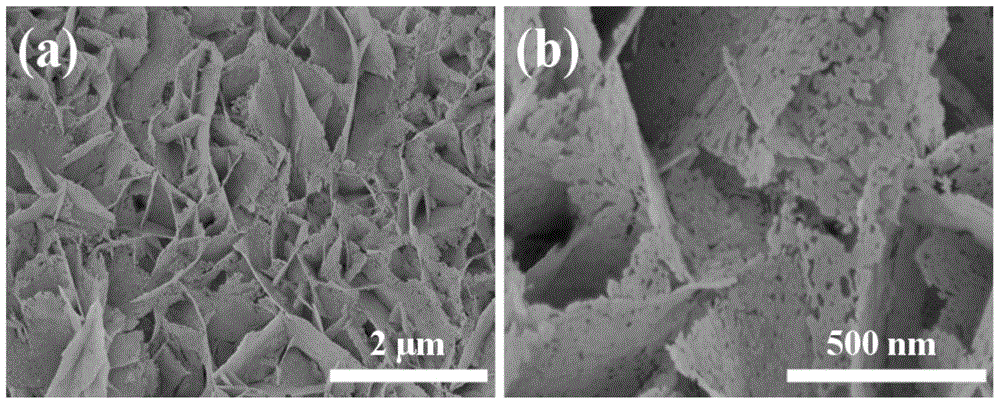

[0024] 2. Porous NiO / CeO 2 Fabrication of nanosheet arrays

[0025] The sample obtained after hydrothermal treatment is calcined in air atmosphere, the calcination temperature is 500°C, and the holding time is 2 hours, and the porous NiO / CeO can be obtained. 2 Nanosheet arrays.

[0026] ...

Embodiment 2

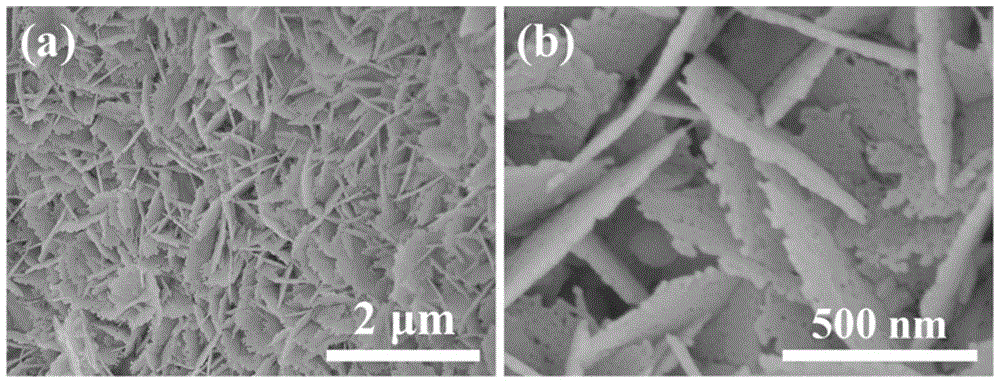

[0028] 1. NiO / CeO 2 Preparation of Nanosheet Array Precursor

[0029] (1) Place nickel foam (2cm*3cm) purchased from the market into 3mol / L hydrochloric acid and ultrasonically clean it for 30 minutes to remove the oxide layer on the surface, then use deionized water and absolute ethanol to clean it alternately;

[0030] (2) Dissolve 0.152g of cerium nitrate, 0.026g of ammonium fluoride and 0.1051g of urea in 35mL of distilled water to form a mixed solution and transfer it to an autoclave;

[0031] (3) placing the nickel foam obtained in step (1) in an autoclave containing the mixed solution obtained in step (2), sealing it and carrying out hydrothermal treatment in an oven at 140° C. for 12 hours;

[0032] 2. Porous NiO / CeO 2 Fabrication of nanosheet arrays

[0033] The sample obtained after hydrothermal treatment is calcined in air atmosphere, the calcination temperature is 500°C, and the holding time is 2 hours, and the porous NiO / CeO can be obtained. 2 Nanosheet arrays...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com