Micro waste water purification machine

A technology for water purifiers and micro-wastewater, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Deal with issues such as the service life of the filter element, and achieve the effect of ensuring the quality of pure water, high quality of pure water, and guaranteeing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

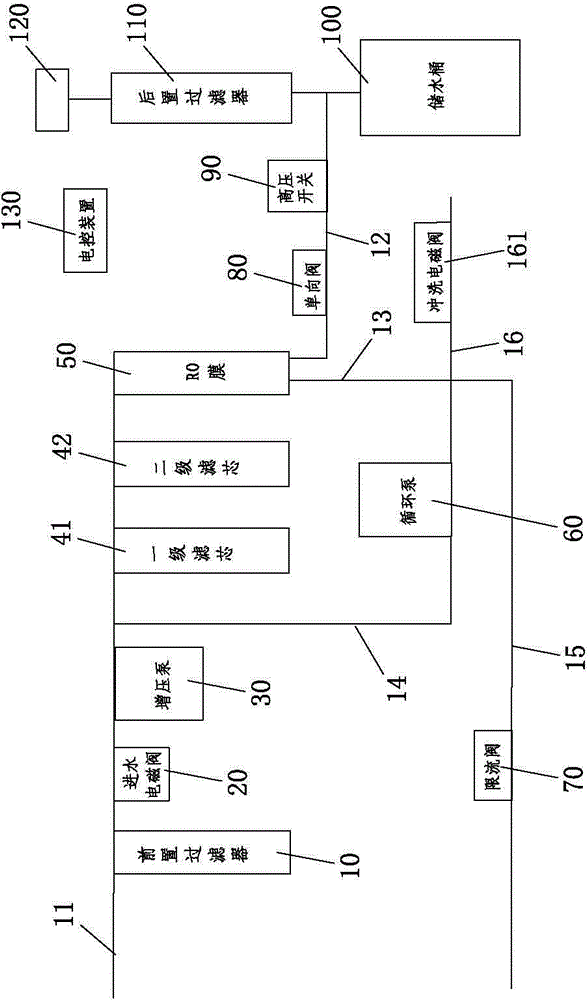

[0032] Such as figure 1 As shown, a micro-waste water purifier of the present embodiment includes a pre-filter 10, a water inlet solenoid valve 20, a booster pump 30, a filter element mechanism and an RO membrane 50 connected sequentially through pipelines, and the water purifier It also includes a circulating pump 60, a restrictor valve 70, a one-way valve 80, a high pressure switch 90, a water storage bucket 100 and a post filter 110,

[0033] The pre-filter 10 is connected to the raw water pipeline 11, the water purification outlet of the RO membrane 50 is connected to the water purification outlet pipe 12, and the one-way valve 80 and the high-pressure switch 90 are sequentially arranged on the water flow direction. A clean water outlet pipe 12, the outlet ends of the clean water outlet pipe 12 are respectively connected to the water storage bucket 100 and the post filter 110;

[0034] The concentrated water outlet of the RO membrane 50 is connected with a concentrated w...

Embodiment 2

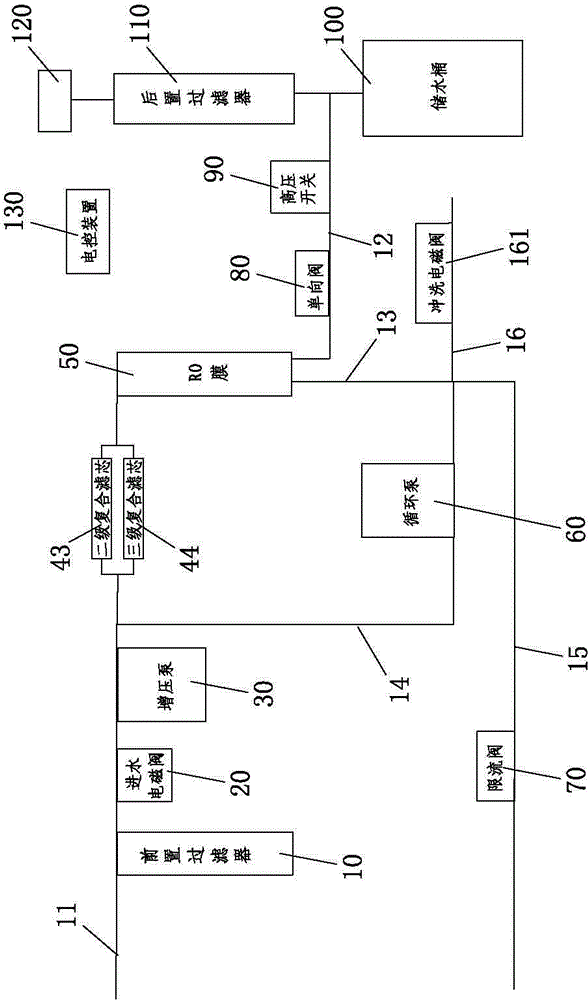

[0053] Such as figure 2 As shown, the filter element mechanism of this embodiment includes a secondary composite filter element 43 and a tertiary composite filter element 44 connected in parallel, and the water outlet ends of the secondary composite filter element 43 and the tertiary composite filter element 44 are connected to the RO membrane 50 respectively. The water inlet end is connected, and the pre-filter 10 is an origami filter element with a pore size of 20 μm. Further, the two-stage composite filter element 43 and the three-stage composite filter element 44 are composite filter elements of activated carbon and PP cotton, the outer layer of the composite filter element is PP cotton with a pore size of 1-5 μm, and the PP cotton is filled with sintered activated carbon .

[0054] The function of the origami filter element is to filter larger particles in the raw water, so that the whole filter system can perform the function of coarse filtration first and then fine fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com