Formula of chemical heat storage material for heat transfer

A chemical heat storage and formulation technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of heat transfer contradictions of chemical substances, useless industrial production, poor heat transfer performance of reversible reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

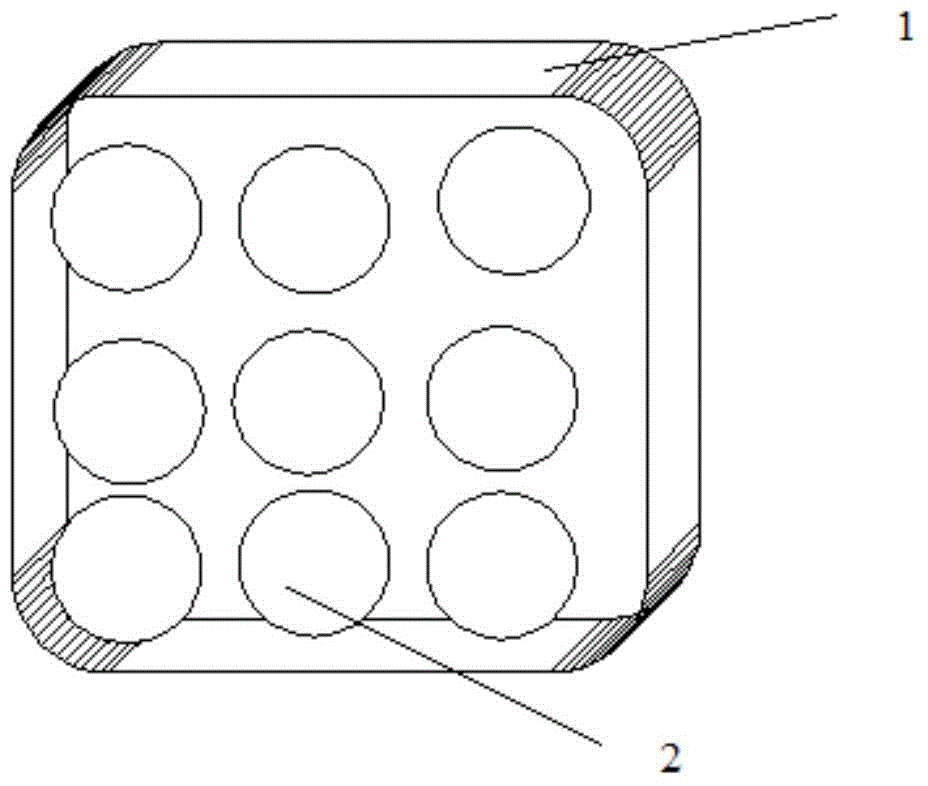

[0045] Embodiment 1, rectangular chemical heat storage block

[0046] figure 1 The rectangular chemical heat storage block shown is composed of chemical substances NaSO in accordance with the weight ratio 4 .10H 2 O500 grams account for 50%, 200 grams of metal particle iron oxide accounts for 20%, and 300 grams of microporous particle zeolite powder accounts for 30%, and they are mixed to become chemical heat storage materials. After mixing it, it is molded by mechanical pressure. There are 9 channels in the rectangular block, and the channels can be formed into a channel, and the fluid can circulate in the channels; the chemical heat storage block can absorb 300 grams of water, and the temperature is 32.3 degrees, when the temperature is higher than this temperature, sensible heat is used for heat storage. This material has good thermal conductivity, can effectively transfer heat energy, and has adsorption capacity, absorbing 300 grams of water to realize chemical heat stor...

Embodiment 2

[0048] Embodiment 2, rectangular chemical heat storage ball

[0049] Chemical substance CaCl by weight ratio 2 .6H 2O 800g accounts for 80%, the metal particles are composed of 100g steel slag 10%, and microporous particle alumina 100g accounted for 10%. After mixing them, they are made into granule balls and become chemical heat storage balls.

[0050]

Embodiment 3

[0051] Embodiment 3, honeycomb empty chemical heat storage fast

[0052] According to the weight ratio chemical substance Mg(NO 3 ) 2 .6H 2 O600g accounts for 60%, 150g of metal particle gold ore tailings powder accounts for 15%, and 100g of microporous particle alumina accounts for 10%, and 15g of graphite powder is composed of 15%. Mix it, then add 180 heat-conducting cement, and mix it It is filled into the container, and the inside of the container is provided with honeycomb holes. When refilling, the filled materials are filled one by one at intervals of a honeycomb hole, and then formed after being fixed.

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com