Method for directly synthesising nitrogen-doped graphene by simply using solid nitrogen source

A technology of nitrogen-doped graphene and nitrogen source, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve problems such as complicated process, and achieve the effect of simple operation, low cost and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

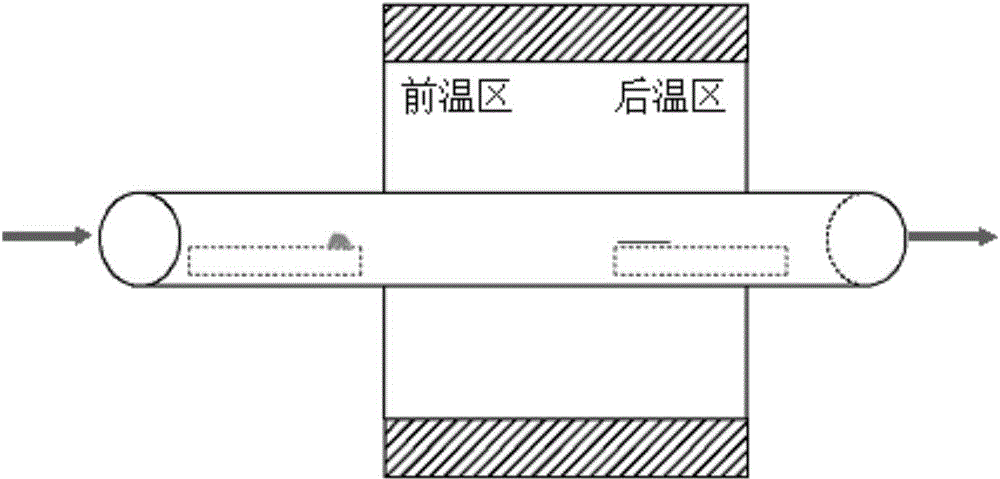

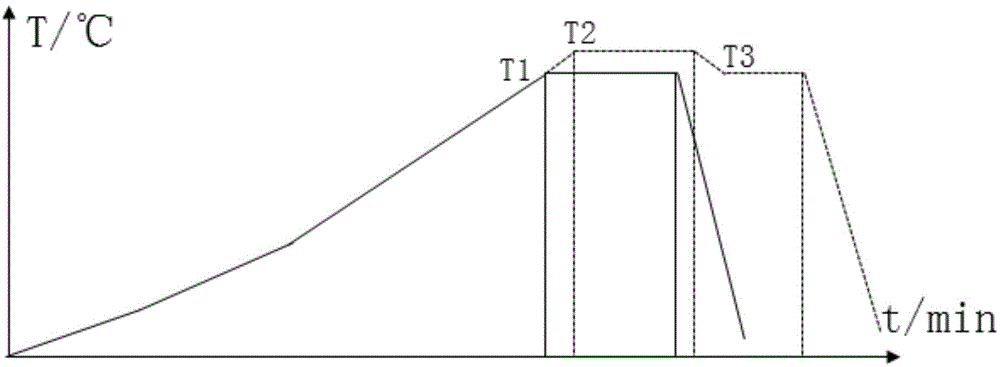

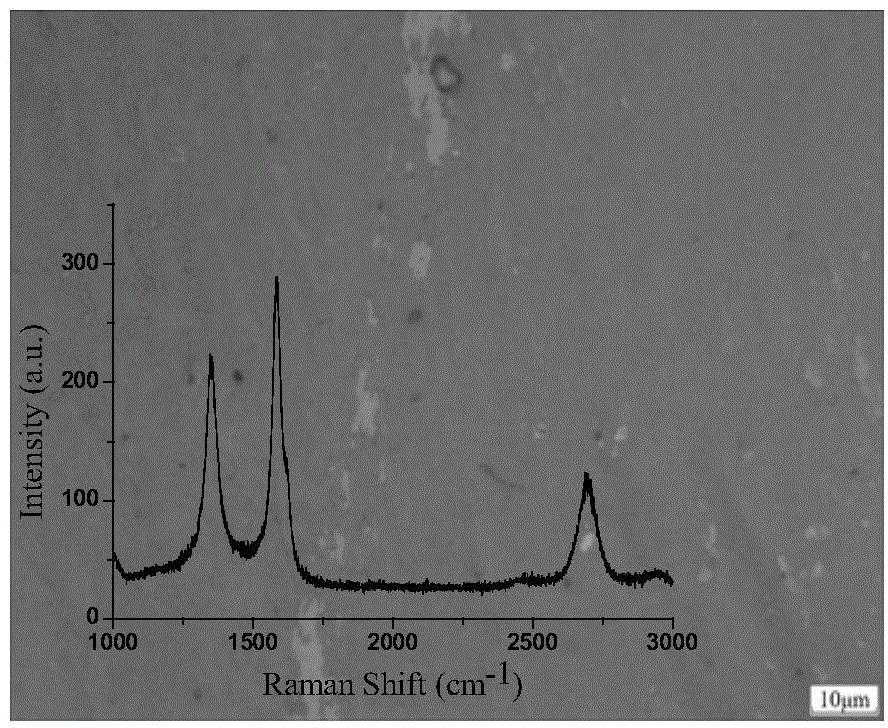

[0020] In the present invention, firstly, the tube furnace with dual temperature zones reaches the temperature to be determined, and H is introduced during the heating process. 2 In order to prevent the oxidation of copper foil, neither the carbon source nor the nitrogen source is passed into the tube furnace during the process. When the temperature reaches the predetermined temperature, the nitrogen and carbon sources on the side of the temperature zone in the airflow direction of the tube furnace are introduced into the tube furnace. It decomposes and dissociates carbon and nitrogen-containing substances, which are transported to the surface of copper foil by carrier gas to undergo a chemical reaction, and then use rapid cooling to generate nitrogen-doped graphene on the surface of copper foil. Among them, the metal substrate used in the process of synthesizing nitrogen-doped graphene by CVD method itself acts as a catalyst, so no additional catalyst is needed here. Moreover, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com