Heat accumulating type multi-generation unit and movable unit

A polygeneration and regenerative technology, which is applied in thermal storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of inability to realize storage and waste, and achieve the effect of energy supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

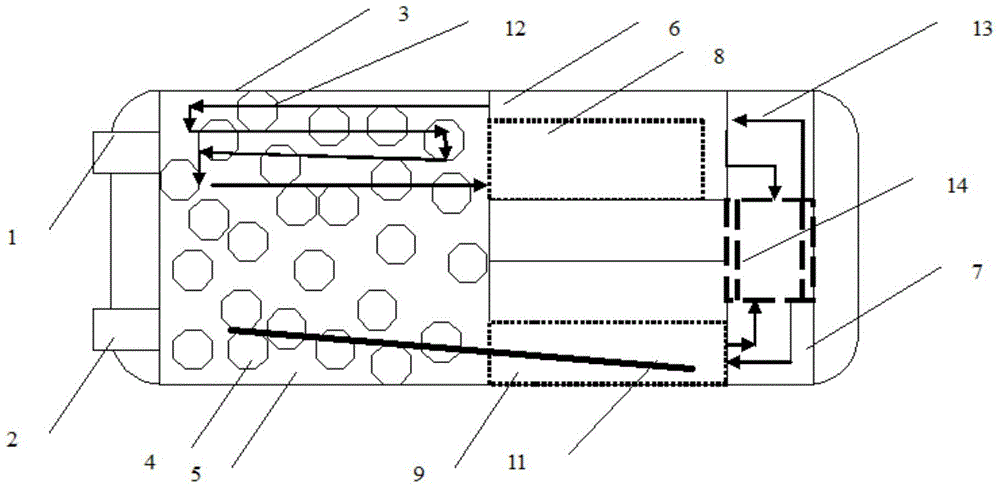

[0056] Embodiment 1, fixed solid block thermal storage polygeneration unit

[0057] figure 1 The fixed solid block heat storage polygeneration unit shown is composed of container 3, heat storage material 4, polygeneration devices (8, 9, 10), and control system 14; heat storage material 4 and polygeneration unit ( 8, 9, 10) and the control system 14 are set in the container 3; there are three cavities inside the container 3, a heat storage material chamber 5, a polygeneration device chamber 6, and another control system Chamber 7, set solid granules in the thermal storage material chamber, which is composed of 30% iron oxide, 40% heat-conducting cement, and 30% sand, which are processed into hexagonal granules and placed in the polygeneration chamber 6 The power generation device 8 and the refrigeration device 9 are provided. The power generation device 8 and the heat storage material complete the heat energy exchange through the fluid heat exchange 12 system, and provide the ...

Embodiment 2

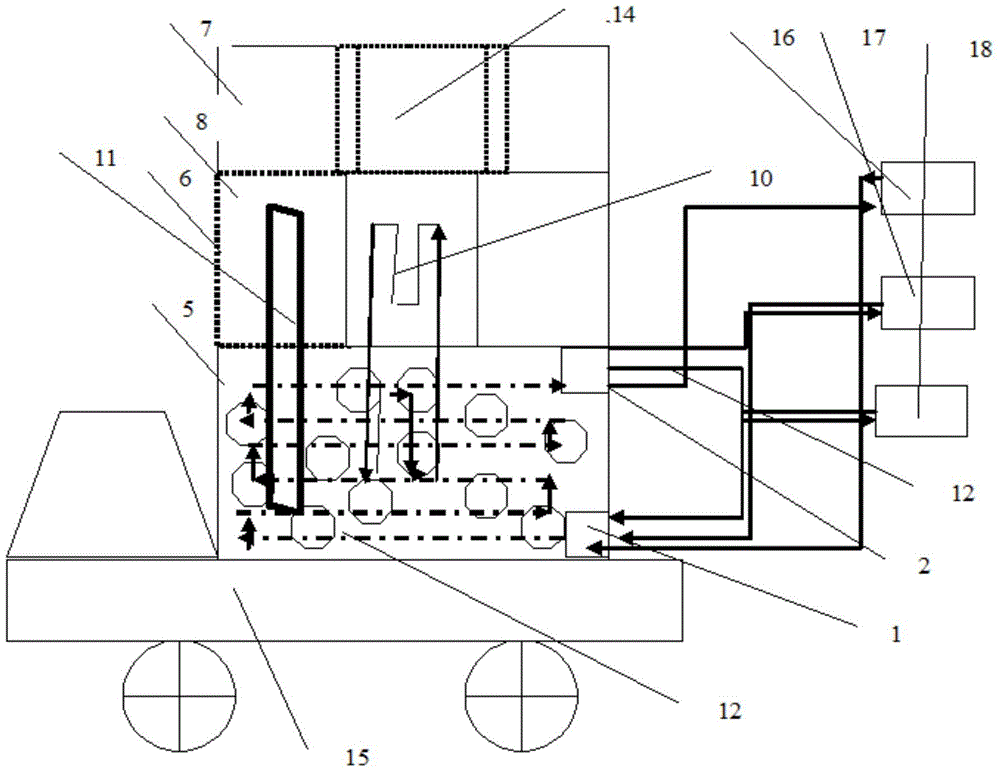

[0061] Embodiment 2, mobile fluid heat storage polygeneration unit

[0062] figure 2 figure 1 The mobile fluid heat storage polygeneration unit shown is composed of transportation equipment 15, container 3, heat storage material 4, polygeneration devices (8, 9, 10), and control system 14; heat storage material 4 and polygeneration The unit (8, 9, 10) and the control system are set 14 in the container 3; there are three cavities inside the container 3, one is a heat storage material chamber 5, one is a polygeneration device chamber 6, and the other is a The control system chamber 7 is provided with a fluid in the heat storage material chamber. The fluid is composed of molten salt, which is composed of 70% potassium nitrate and 30% sodium nitrate. The polygeneration chamber 6 is provided with a power generation device 8 and a water heater 10 units, the power generation device 8 and the heat storage material complete the heat energy exchange through the circulating heat pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com