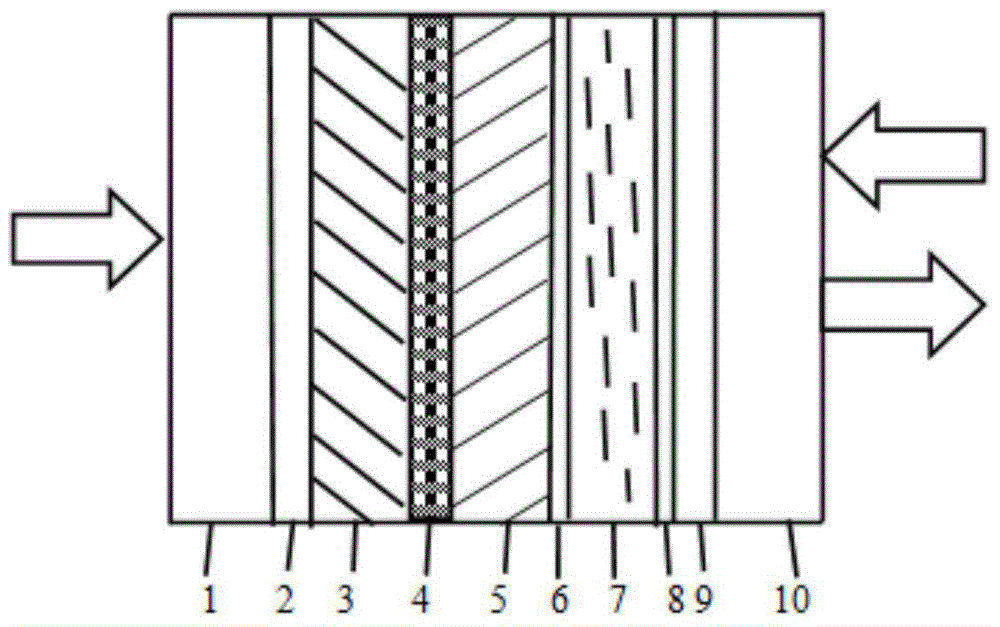

Liquid crystal light valve and preparation method thereof

A liquid crystal light valve and photosensitive layer technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems that it is difficult to meet the requirements of the high-resolution liquid crystal light valve photosensitive layer, affect the resolution of the liquid crystal light valve, and the mobility is insufficient. Achieve the effects of improving resolution and photosensitivity, shortening response time, and easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

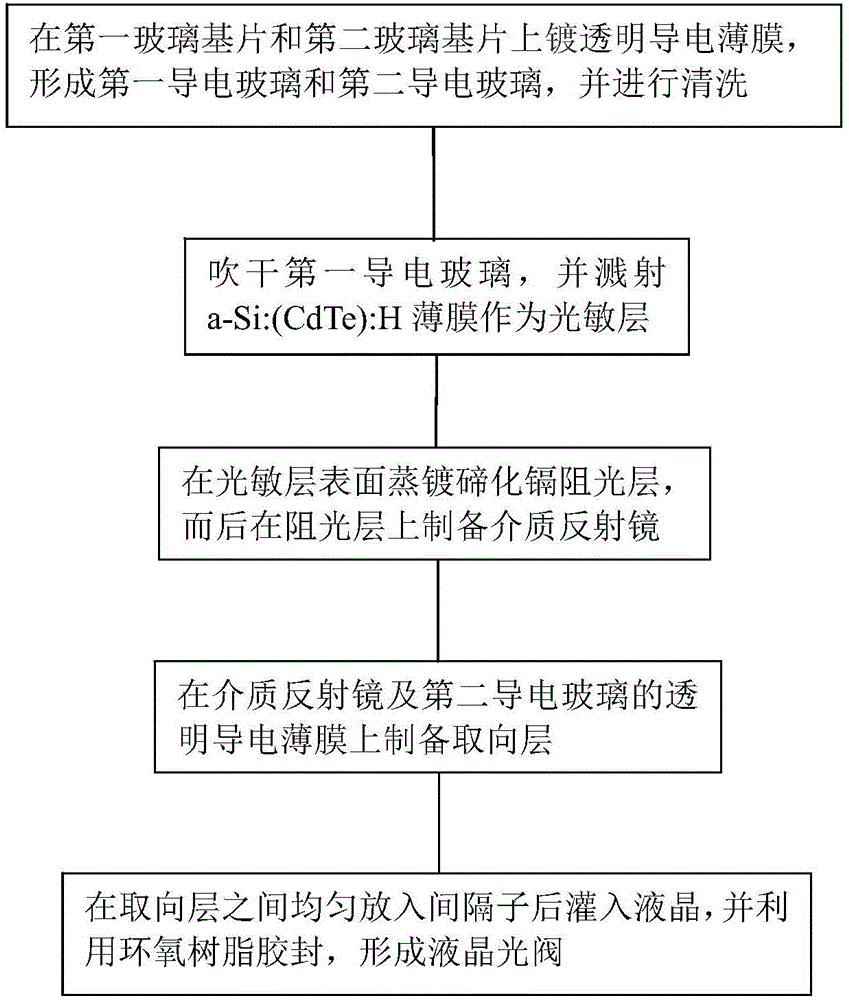

[0042] In this example, the preparation method of the liquid crystal light valve is specifically:

[0043] 1. Coating ITO films on one side of the first glass substrate and the second glass substrate respectively to form the first conductive glass and the second conductive glass, and then perform wet treatment on the ITO surface, that is, the first conductive glass and the second conductive glass The conductive glass is soaked in detergent for 15 minutes, then ultrasonically treated in ethanol or acetone solution for 15 minutes, and then hydrogen peroxide is used to treat the ITO surface, that is, a mixed solution of water: hydrogen peroxide: ammonia = 5:1:1 is ultrasonically treated for 15 minutes to remove Organic matter such as grease on the surface of the first conductive glass and the second conductive glass eliminates some dangling bonds, increases hydrophilic groups, and improves the adhesion of the substrate. Finally, put them into deionized water, and take them out aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com