Top-emitting white light organic light emitting device

An electroluminescent device and top-emission technology, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve problems affecting performance, etc., and achieve the effect of improving color rendering index, good spectral characteristics and efficiency performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

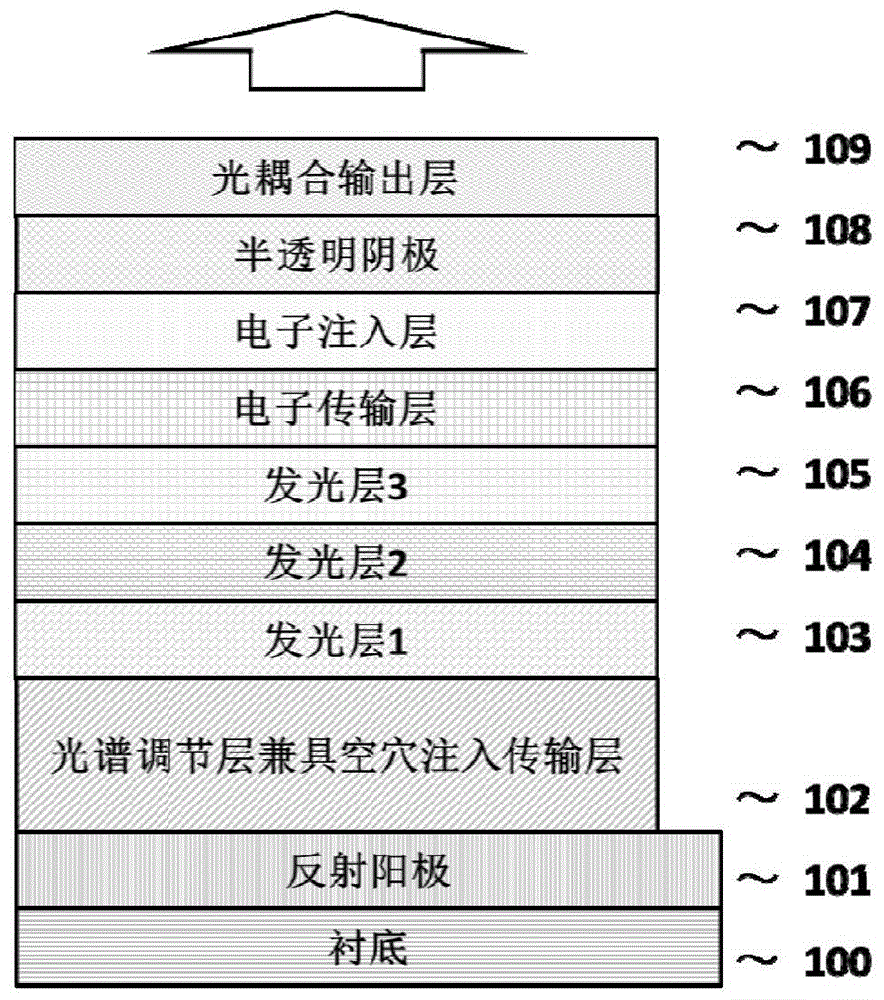

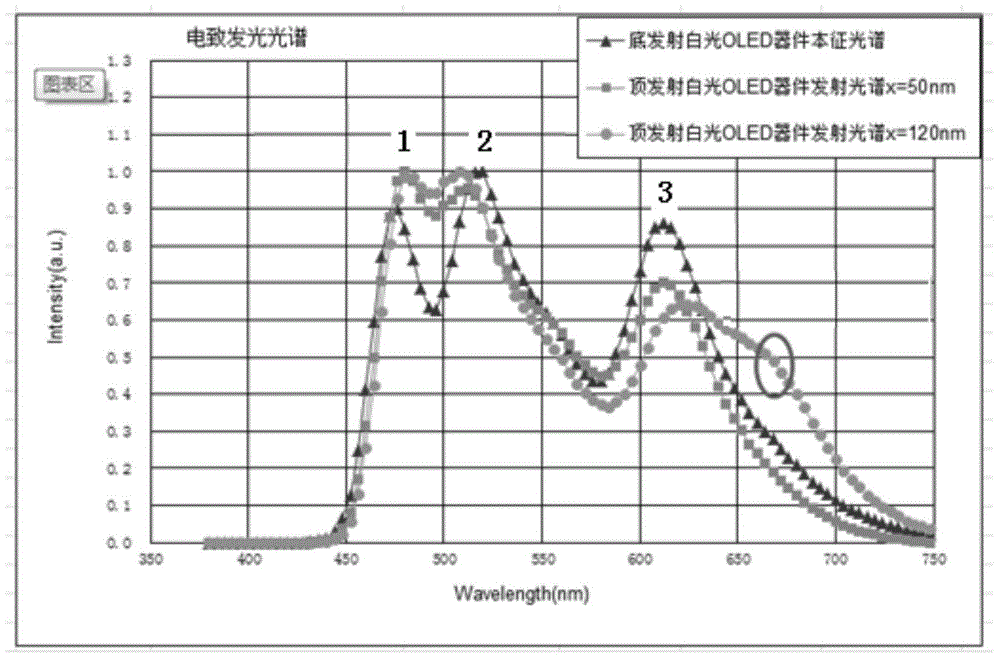

[0055] as attached figure 1 As shown, the top-emitting white light organic electroluminescent device of the present invention includes a base substrate 100, a reflective anode 101, a spectrum adjustment layer 102, a first light-emitting layer 103, and a second light-emitting layer 104 in order from bottom to top. , the third light emitting layer 105, the electron transport layer 106, the electron injection layer 107, the translucent cathode 108 and the light outcoupling layer 109. in,

[0056] The substrate substrate is glass; the reflective anode is an Ag layer; the translucent cathode is a doped layer of Mg and Ag, and an Ag layer is added behind it. The electron transport layer is Bphen , the electron injection layer is LiF. The luminescent materials of the first luminescent layer, the second luminescent layer, and the third luminescent layer are respectively host-1 doped with RD-1, host-2 doped with GD-1, and BH-1 doped with BD-1, corresponding to The doping concentra...

Embodiment 2

[0076] The top-emitting white light organic electroluminescent device described in this embodiment is the same as that in Embodiment 1, both of which have an upright structure, and the only difference is that it is a double light-emitting center structure, that is, only includes a first light-emitting layer and a second light-emitting layer. The first light emitting layer and the second light emitting layer are blue light emitting layer and yellow light emitting layer respectively. Both the first light-emitting layer and the second light-emitting layer are fluorescent. The luminescent materials of the first luminescent layer and the second luminescent layer are respectively BH-1 doped with BD-1 and host-3 doped with YD-1, and the corresponding doping concentrations are 5wt% and 3wt%, respectively, and are controlled respectively The physical thicknesses of the first light-emitting layer and the second light-emitting layer are respectively 10nm and 20nm, so that the total optic...

Embodiment 3

[0089] The structure and preparation method of the top-emitting white light organic electroluminescent device described in this example are the same as those in Example 2, both of which are upright structures, and the only difference is that the spectrum adjustment layer is different.

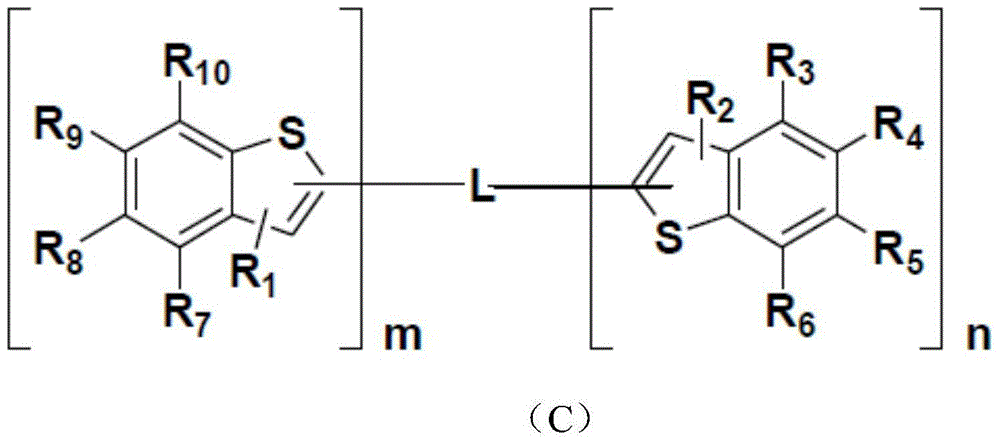

[0090] The spectrum adjustment layer in this embodiment is a single layer, or a double layer, a doped single layer structure, or a doped double layer structure, and the optical thickness of the spectrum adjustment layer is controlled to be 50 nm. The materials selected for the spectrum adjustment layer include compound 1-18 or 1-20, and the refractive index of the compound 1-18 or 1-20 is 1.59 (470nm). The specific material selection is shown in Table 3 below.

[0091] The first light-emitting layer and the second light-emitting layer are respectively a blue light-emitting layer and a yellow light-emitting layer. Both the first luminescent layer and the second luminescent layer are fluorescent....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical thickness | aaaaa | aaaaa |

| Optical thickness | aaaaa | aaaaa |

| Optical thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com