Yeast culture and preparation method thereof

A technology of yeast culture and yeast, which is applied in animal feed, animal feed, application, etc., can solve the problems of low number of viable bacteria, low fermentation effect, and inability of yeast to fully utilize solid fermentation raw materials, so as to achieve rich enzyme system and high yield Strong enzyme effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

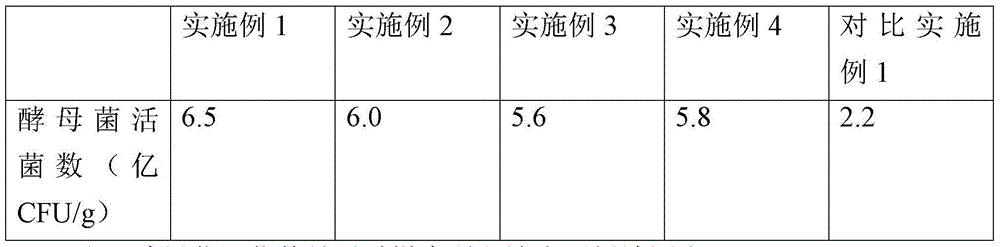

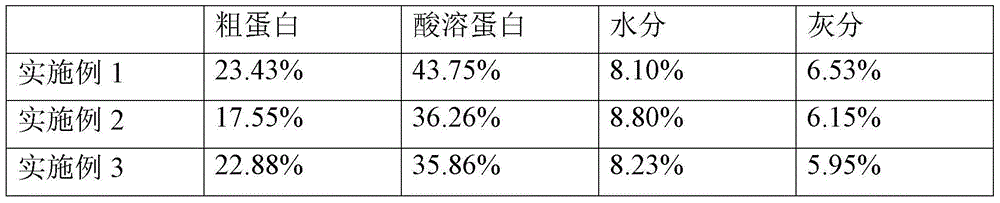

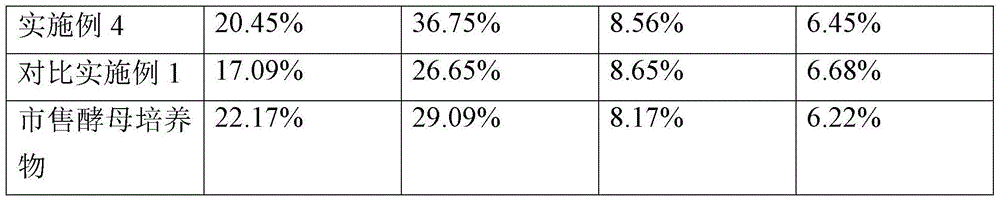

Examples

Embodiment 1

[0027] As an embodiment of the present invention, the preparation method of the yeast culture comprises the following steps:

[0028] (1) Activate the strain of Saccharomyces cerevisiae, then inoculate the isolated and purified Saccharomyces cerevisiae into the primary shake flask culture medium, the medium capacity of 500ml Erlenmeyer flask is 100ml, shake the flask at 28~30℃, 180~200rpm Cultivate for 17-24 hours to obtain the primary seed liquid, then inoculate the primary seed liquid into the secondary shake flask culture medium, fill a 2000ml Erlenmeyer flask with a volume of 450ml, and culture the shake flask at 28°C-30°C and 180-200rpm for 20-24h. Wherein, the seed medium of the yeast is YEPD liquid medium, and the composition of the YEPD liquid medium is: glucose 20g, peptone 20g, yeast powder 10g, 1000ml water, natural pH. The medium was sterilized at 115° C. for 30 minutes at high temperature.

[0029] In this embodiment, the Saccharomyces cerevisiae is Saccharomyces...

Embodiment 2

[0040] As an embodiment of the present invention, the preparation method of the yeast culture comprises the following steps:

[0041] (1) Activate the strain of Saccharomyces cerevisiae, then inoculate the isolated and purified Saccharomyces cerevisiae into the primary shake flask culture medium, the medium capacity of 500ml Erlenmeyer flask is 100ml, shake the flask at 28~30℃, 180~200rpm Cultivate for 17-24 hours to obtain the primary seed liquid, then inoculate the primary seed liquid into the secondary shake flask culture medium, fill a 2000ml Erlenmeyer flask with a volume of 450ml, and culture the shake flask at 28°C-30°C and 180-200rpm for 20-24h. Wherein, the seed medium of the yeast is YEPD liquid medium, and the composition of the YEPD liquid medium is: glucose 25g, peptone 20g, yeast powder 12g, 1000ml water, natural pH. The medium was sterilized at 115° C. for 30 minutes at high temperature.

[0042] In this embodiment, the Saccharomyces cerevisiae is Saccharomyces...

Embodiment 3

[0053] As an embodiment of the present invention, the preparation method of the yeast culture comprises the following steps:

[0054] (1) Activate the strain of Saccharomyces cerevisiae, then inoculate the isolated and purified Saccharomyces cerevisiae into the primary shake flask culture medium, the medium capacity of 500ml Erlenmeyer flask is 100ml, shake the flask at 28~30℃, 180~200rpm Cultivate for 17-24 hours to obtain the primary seed liquid, then inoculate the primary seed liquid into the secondary shake flask culture medium, fill a 2000ml Erlenmeyer flask with a volume of 450ml, and culture the shake flask at 28°C-30°C and 180-200rpm for 20-24h. Wherein, the seed medium of the yeast is YEPD liquid medium, and the composition of the YEPD liquid medium is: glucose 18g, peptone 22g, yeast powder 10g, 1000ml water, natural pH. The medium was sterilized at 115° C. for 30 minutes at high temperature.

[0055] In this embodiment, the Saccharomyces cerevisiae is Saccharomyces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com