Quality improvement method of instant sausage

A sausage and total mass technology, applied in the field of food processing, can solve the problems of low yield, poor quality characteristics, low yield of ready-to-eat sausages, etc., and achieve the effect of improving product yield, stickiness and chewiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

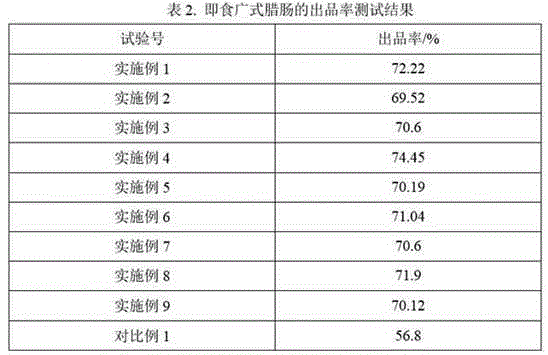

Examples

Embodiment 1

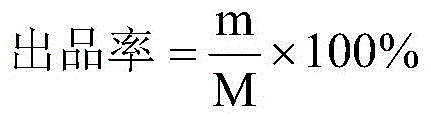

[0049] Embodiment 1 The making of instant Cantonese-style sausage

[0050] S1. Raw material processing: Grind the lean pork with a meat grinder for later use; cut the fat meat into cubes of 6*6*6mm with a dicing machine, wash off the slick oil with hot water at 60~70°C, and set aside; Pork and fat meat are the main ingredients, and the mass ratio of lean pork and fat meat in the main ingredients is 7:3;

[0051] S2. Filling: Weigh 100kg of main ingredients; 8.0kg of auxiliary materials sugar, 4kg of sorghum wine (alcohol content 53%), 0.4g of monosodium glutamate, 150ppm of sodium nitrite, 0.1kg of tripolyphosphate, 0.15kg of hexametaphosphate and 0.1 kg pyrophosphate. Dissolve the auxiliary material in 18kg of water, pour it into the main material and stir evenly to form a meat filling;

[0052] S3. Filling: Fill the prepared meat stuffing into the casing, and remove air bubbles during filling;

[0053] S4. Baking: The baking process is 52°C for 4h; 58°C for 4h; 52°C for 34h...

Embodiment 2

[0056] Embodiment 2 The making of instant Cantonese-style sausage

[0057] The preparation method is the same as in Example 1, except that in the process of making stuffing, 0.1 kg of tripolyphosphate, 0.2 kg of hexametaphosphate and 0.15 kg of pyrophosphate are added.

Embodiment 3

[0058] Embodiment 3 The making of instant Cantonese-style sausage

[0059] The preparation method is the same as that in Example 1, except that in the filling process, 0.1 kg of tripolyphosphate, 0.25 kg of hexametaphosphate and 0.2 kg of pyrophosphate are added.

PUM

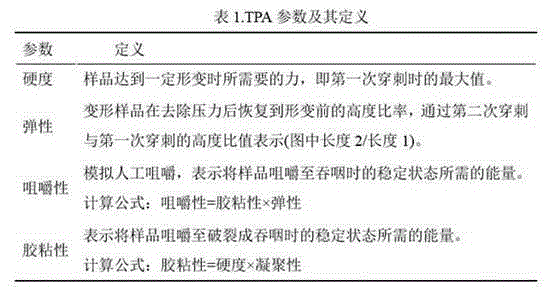

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Elasticity | aaaaa | aaaaa |

| Chewiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com