Creeping type welding robot system

A welding robot and sensing system technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as poor stability, large resistance, poor turning radius and center accuracy, and achieve good stability , Easy to operate, good maneuverability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

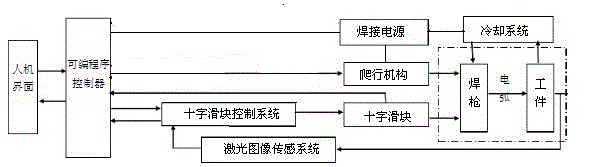

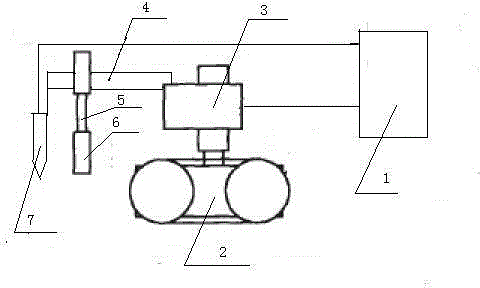

[0026] Such as figure 1 As shown, a crawling welding robot system, the system includes: a welding power supply that provides electric energy to the welding robot system; a laser image sensing system that obtains image information of the weld from the scene; a cross slider control system that controls the laser The image information obtained by the image sensing system is processed, and the deviation signal of the weld is extracted after processing; the cross slider, the cross slider receives the deviation signal provided by the cross slider control system to move; the permanent magnet crawler mechanism, the permanent magnet The driving mechanism of the crawler mechanism adopts an AC servo system, and the AC servo system includes a reduction mechanism, an amplifier and a motor; a programmable controller. After setting various parameters on the man-machine interface, the programmable controller receives the signal obtained by the laser image sensor system to obtain the image inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com