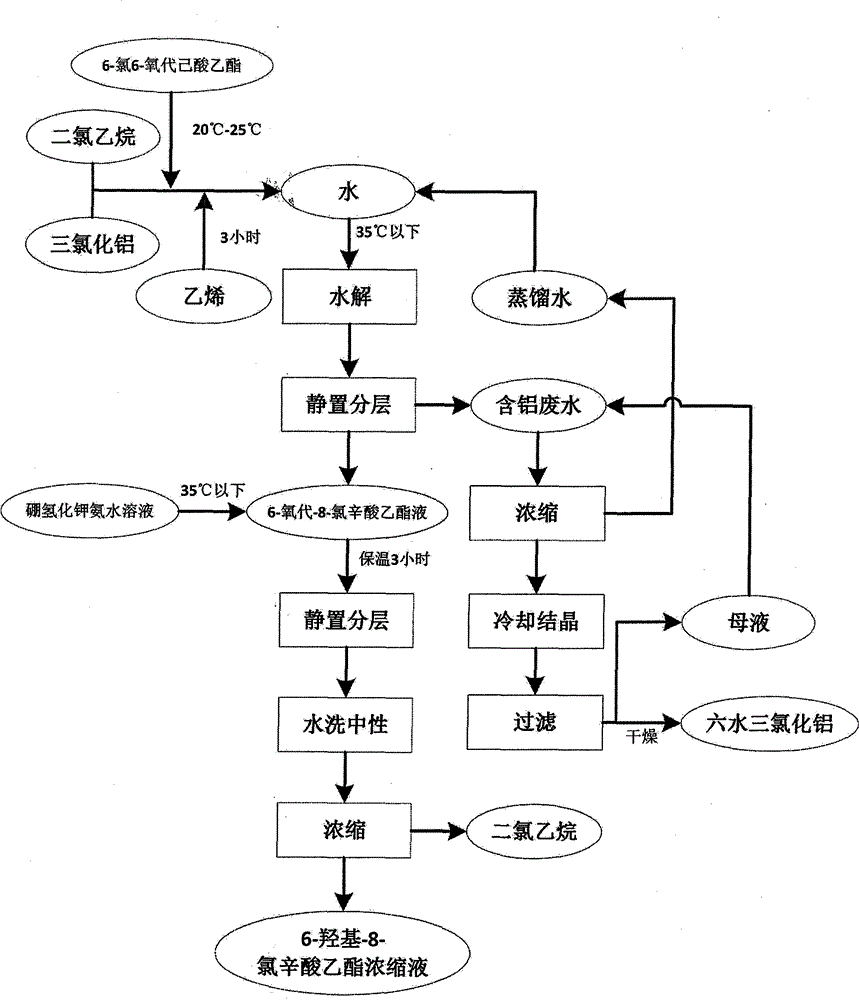

Method for treating aluminum-containing wastewater in preparation process of 6-oxo-8-chloro ethyl caprylate

A technology for the preparation of ethyl chlorooctanoate, which is applied in the field of treating aluminum-containing wastewater, can solve the problems of large amount of aluminum-containing wastewater, difficulty in resource treatment, low aluminum ion content, etc., and achieves production cost reduction, obvious advantages in resource utilization, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

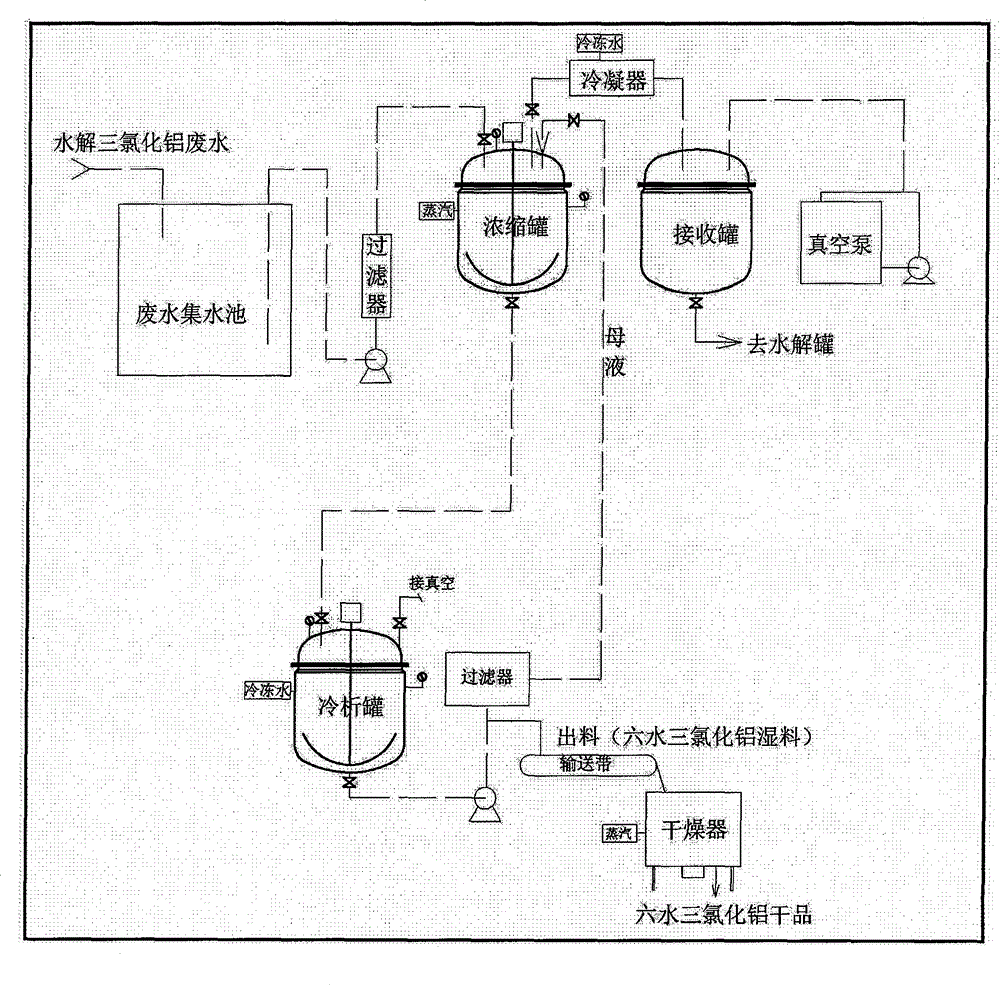

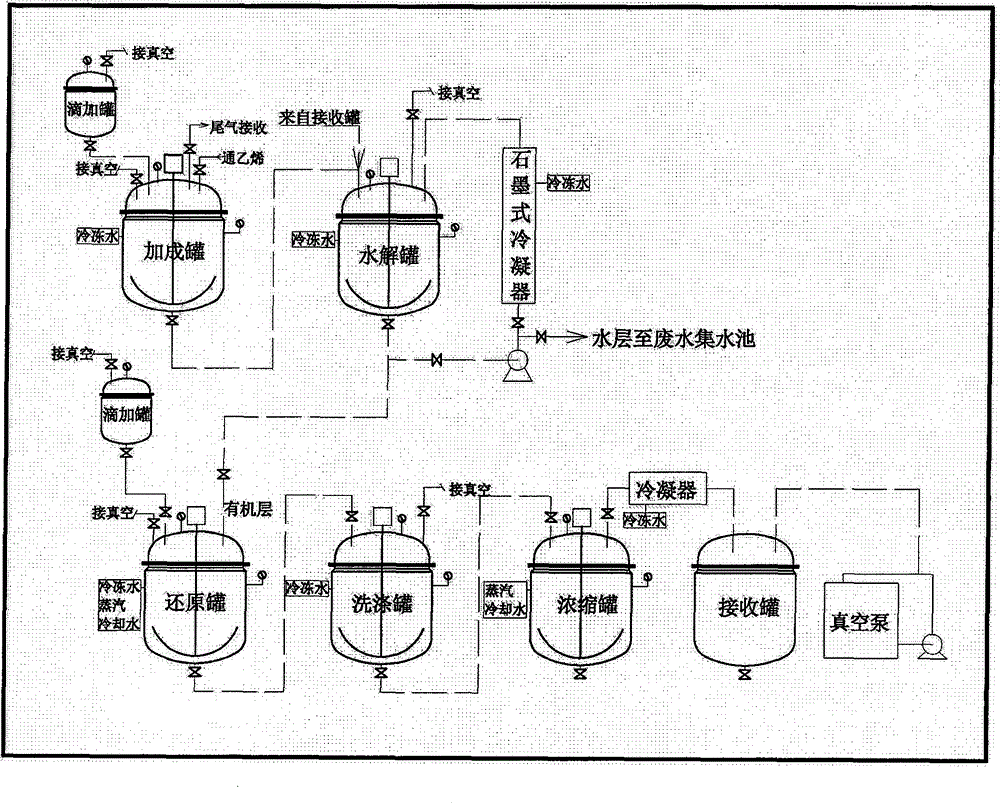

[0039] According to the similar preparation method of 6-oxo-8-chlorooctanoic acid ethyl ester described in CN102731307A, put 1050kg water into 3M 3 In the hydrolysis kettle, ice salt water is passed into the jacket of the hydrolysis kettle. The hydrolysis kettle is equipped with a circulation pump and a circulation pipeline. The circulation pipeline is connected to a graphite condenser. Brine, the material is cooled and then recycled back to the hydrolysis tank. Use a jacket and a graphite condenser to circulate and cool the water in the hydrolysis tank to below 10°C for later use.

[0040] Add 1280Kg of dichloroethane into a 1500L reaction kettle, put in 450Kg of aluminum trichloride, stir, cool down to 10°C-18°C with an ice-salt water jacket, add dropwise 360kg of ethyl 6-chloro-6-oxohexanoate, and The temperature was controlled at 20°C to 25°C, and ethylene was passed through for 3 hours to obtain an addition reaction solution. Put the reaction solution into the spare 105...

Embodiment 2

[0043] Put the last batch of distilled water into 3M 3 In the hydrolysis kettle, add water to 1050kg, put ice salt water into the jacket of the hydrolysis kettle, install a circulation pump and a circulation pipeline in the hydrolysis kettle, and connect a graphite condenser to the circulation pipeline, and the materials in the hydrolysis kettle enter the graphite condenser through the circulation pump, and the graphite condenser The ice brine is passed into the water, and the material is cooled and then circulated back to the hydrolysis kettle. Use a jacket and a graphite condenser to circulate and cool the water in the hydrolysis tank to below 10°C for later use.

[0044]Add 1280Kg of dichloroethane into a 1500L reaction kettle, add 450Kg of aluminum trichloride, stir, cool down to 10°C-18°C with an ice-salt water jacket, add dropwise 360kg of ethyl 6-chloro-6-oxohexanoate, and Control the temperature at 20°C to 25°C, and pass through ethylene for 3 hours to obtain the addi...

Embodiment 3

[0047] Put 1350kg of water into 3M 3 In the hydrolysis kettle, ice salt water is passed into the jacket of the hydrolysis kettle. The hydrolysis kettle is equipped with a circulation pump and a circulation pipeline. The circulation pipeline is connected to a graphite condenser. Brine, the material is cooled and then recycled back to the hydrolysis tank. Use a jacket and a graphite condenser to circulate and cool the water in the hydrolysis tank to below 10°C for later use.

[0048] Add 1280Kg of dichloroethane into a 1500L reaction kettle, put in 450Kg of aluminum trichloride, stir, cool down to 10°C-18°C with an ice-salt water jacket, add dropwise 360kg of ethyl 6-chloro-6-oxohexanoate, and The temperature was controlled at 20°C to 25°C, and ethylene was passed through for 3 hours to obtain an addition reaction solution. Put the reaction solution into the spare 1350kg water in the hydrolysis kettle, stir it, and then enter the graphite condenser through the circulating pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com