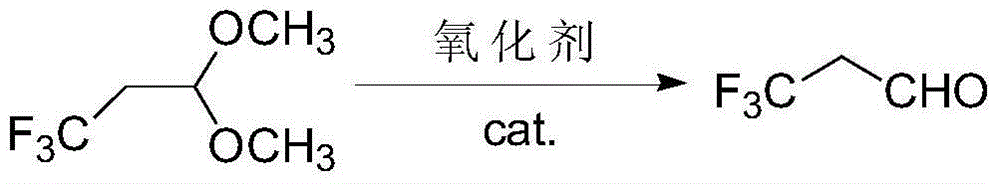

Production process of 3,3,3-trifluoro- propyl aldehyde

A technology for trifluoropropionaldehyde and trifluoropropene, which is applied in the field of preparing 3,3,3-trifluoropropionaldehyde, and can solve the problems that trifluoromethyl iodide raw materials are not readily available, expensive, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Lower the temperature of the reaction bottle to -15°C to -10°C, add 104g of 35% mass concentration of hydrochloric acid, 5.6g of iron powder, and 453g of 30% mass concentration of hydrogen peroxide under stirring, and continue stirring for 1 hour to prepare an oxidizing reagent. Add 158g of 1,1,1-trifluoro-3,3-dimethoxypropane into another reaction flask, then heat it to 100°C under stirring, slowly add the oxidizing reagent dropwise, after the dropwise addition, continue to react for 2 more Hours, the reaction is over, cooled, and then distill off the fraction at 40-70°C, and then collect the fraction at 56°C by rectification to obtain 78g of 3,3,3-trifluoropropanal, 3,3,3-trifluoropropanal The yield of propionaldehyde is 69.6%.

[0033] According to the nuclear magnetic structure identification, the prepared product is indeed 3,3,3-trifluoropropanal, the data are as follows:

[0034] MS: m / z112 (M + ), 64(100).

[0035] 1 HNMR (CDCl 3 ): δ / ppm3.22 (m, 2H), 9.72 (...

Embodiment 2

[0037] Lower the temperature of the reaction flask to -15°C to -10°C, add 104g of hydrochloric acid with a mass concentration of 35% under stirring, V 2 o 5 9g, 453g of hydrogen peroxide at 30% mass concentration, and continued to stir for 1 hour to prepare the oxidizing reagent. Add 158g of 1,1,1-trifluoro-3,3-dimethoxypropane into another reaction flask, then heat it to 100°C under stirring, slowly add the oxidizing reagent dropwise, after the dropwise addition, continue to react for 2 more Hours, the reaction was over, cooled, and then distilled out the fraction at 40-70°C, and then collected the fraction at 56°C by rectification to obtain 89g of 3,3,3-trifluoropropanal, 3,3,3-trifluoropropanal The yield of propionaldehyde is 79.4%.

Embodiment 3

[0039]Lower the temperature of the reaction flask to -15°C to -10°C, add 104g of 35% mass concentration hydrochloric acid, FeCl 3 8g, 453g of hydrogen peroxide at 30% mass concentration, and continued to stir for 1 hour to prepare the oxidizing reagent. Add 158g of 1,1,1-trifluoro-3,3-dimethoxypropane into another reaction flask, then heat it to 100°C under stirring, slowly add the oxidizing reagent dropwise, after the dropwise addition, continue to react for 2 more Hours, the reaction is over, cooled, and then distill off the fraction at 40-70°C, and then collect the fraction at 56°C by rectification to obtain 96g of 3,3,3-trifluoropropanal, 3,3,3-trifluoropropanal The yield of propionaldehyde is 85.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com