Preparation method for slump retaining agent for polycarboxylate superplasticizer

A technology of slump retention agent and water reducer, which is applied in the field of preparation of slump retention agent for polycarboxylate water reducer, can solve the problems of high requirements, instability, complicated preparation process, etc. Effects of slump loss, improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the content of the present invention, the following examples are specifically cited to describe the present invention in further detail. The examples are given by way of illustration, but in no way limit the content of the invention. The protection scope of the present invention shall be determined by the description of the claims.

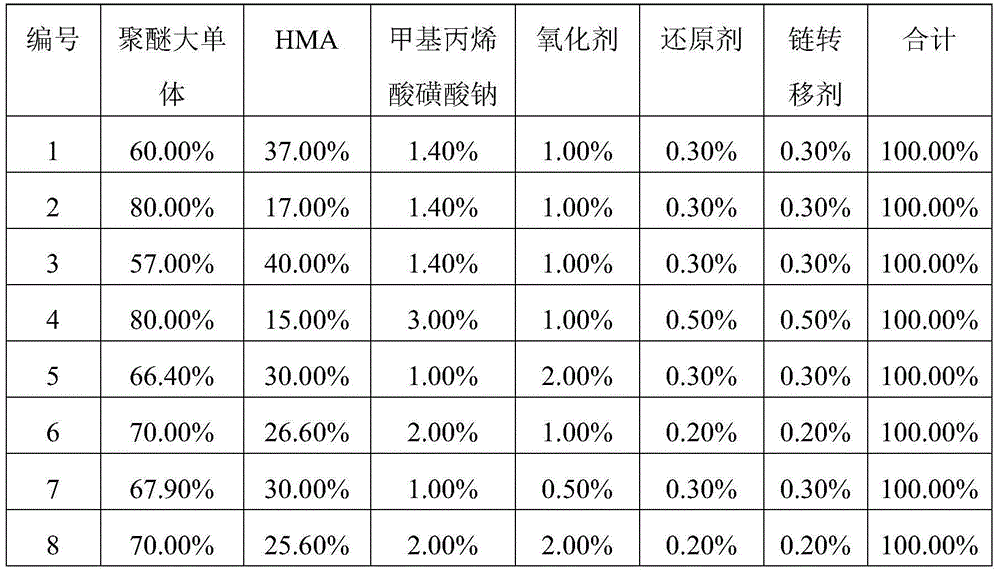

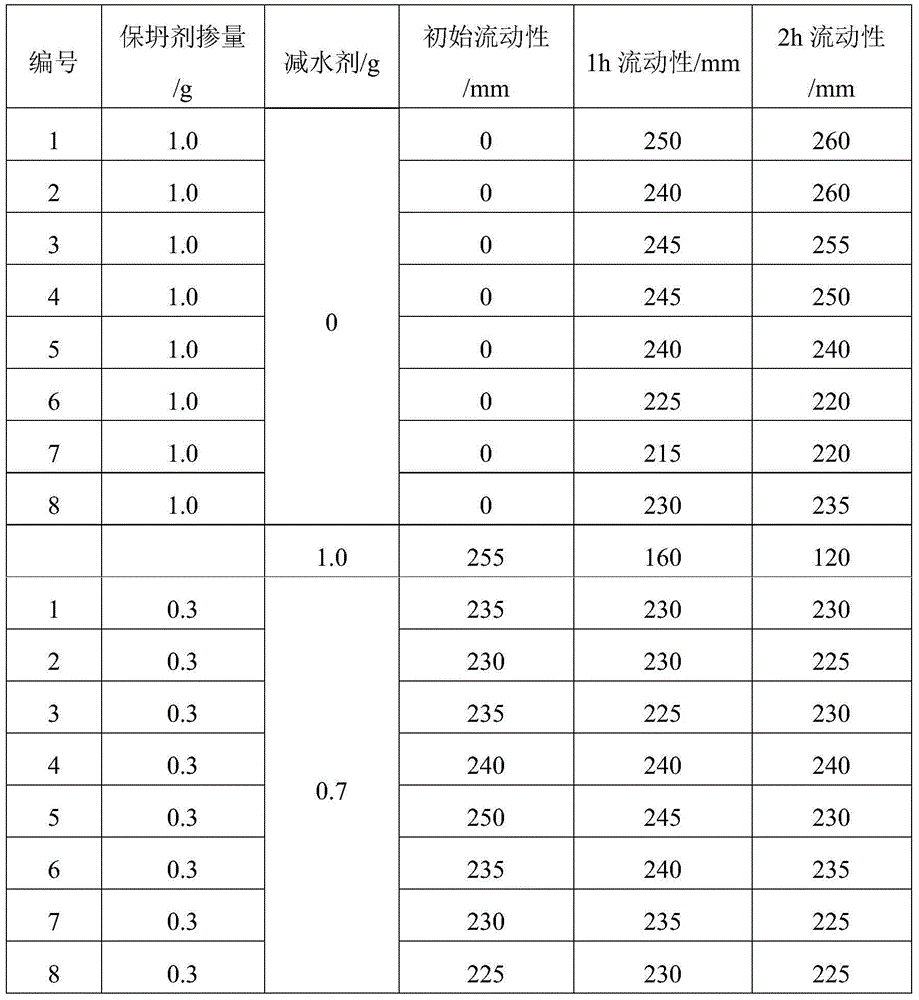

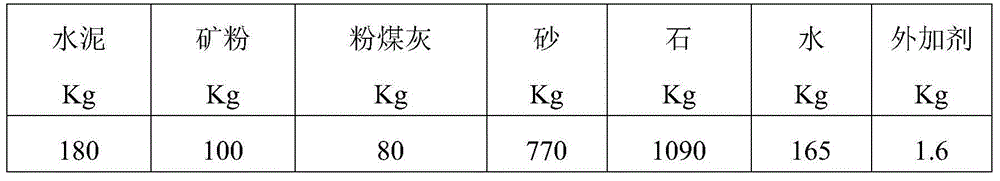

[0021] Embodiment matching is as shown in table 1, and concrete implementation process is as follows:

[0022] 1) Mix maleic anhydride, methanol and p-toluenesulfonic acid, stir evenly, and raise the temperature to 45±1°C, stir at constant temperature for 3.0 hours, and cool to room temperature to obtain a mixture of maleic anhydride and maleic anhydride ester (HMA), Refer to Table 1 for the ratio of materials.

[0023] Table 1 prepares the material proportion of HMA

[0024] Numbering

maleic anhydride

p-Toluenesulfonic acid

total

1

76.00%

23.00%

1.00%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com