Poly-butylene succinate/natural rubber composite degradable toughness material and preparation method thereof

A technology of polybutylene succinate and polybutylene succinate, which is applied in the field of polybutylene succinate/natural rubber composite degradable tough materials, can solve the problem of low elongation at break and limited The scope of application, air pollution and other problems, to achieve excellent mechanical properties, wide application prospects, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

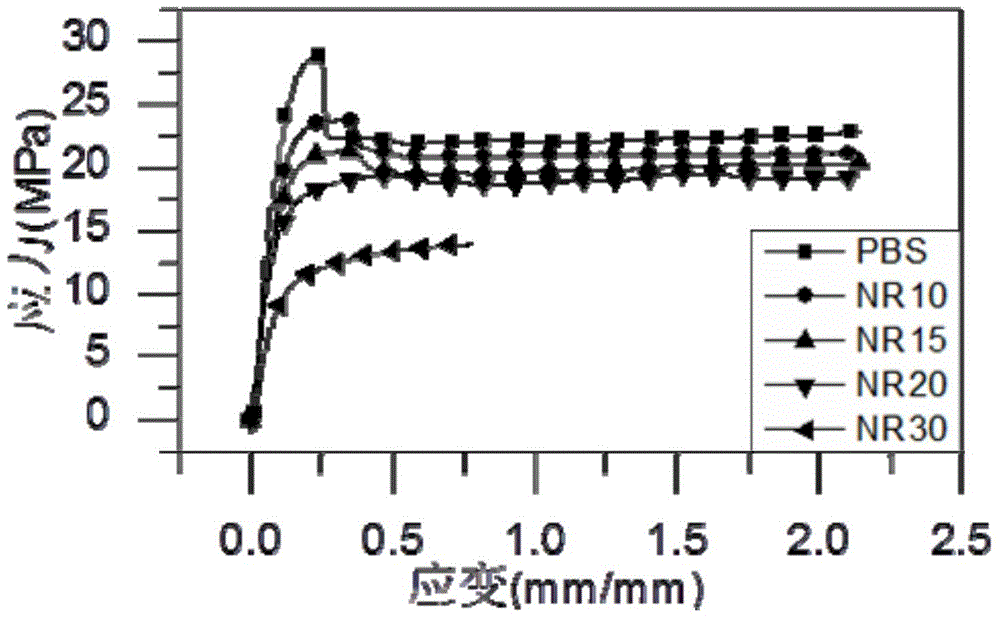

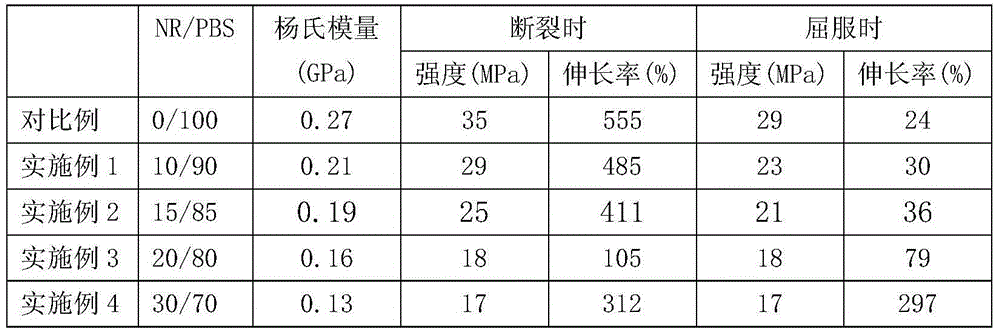

Embodiment 1

[0029] After mixing 90 parts of polybutylene succinate, 10 parts of natural rubber and kneading on an open mill at 90-150 °C for 10-30 minutes, they are molded on a flat vulcanizer (125-145 °C) to obtain poly Butylene succinate / natural rubber composite degradable material.

Embodiment 2

[0031] Mix 85 parts of polybutylene succinate, 15 parts of natural rubber and 1% lubricant at 90-150°C on an open mill for 10-30 minutes and mix them evenly, then put them on a flat vulcanizer (125-145°C ) into a polybutylene succinate / natural rubber composite degradable material.

Embodiment 3

[0033] Mix 80 parts of polybutylene succinate and 20 parts of natural rubber in an open mill at 90-150°C for 10-30 minutes and mix evenly, then shape it on a flat vulcanizer (125-145°C) to obtain polybutylene Butylene glycol diacid / natural rubber composite degradable material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com