Pigment carbon black reacting furnace with super-long remaining section and pigment carbon black produced by the pigment carbon black reacting furnace

A pigment carbon black and reaction furnace technology, applied in the direction of fibrous fillers, etc., can solve the problems of non-compliance with environmental protection, health and safety, aggravate the difficulty of carbon black dispersion, and harm to human health, so as to improve the light transmittance of toluene and high coloring strength , Improve the effect of surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

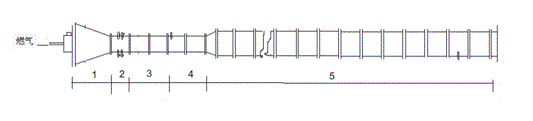

[0040] In the production of pigment carbon black on the traditional furnace carbon black production line, the structure of the combustion section, throat section, reaction section, and quenching section of the reaction furnace are exactly the same, and the control process and control parameters of all the reaction furnaces are also exactly the same, only the residence section is changed. The length of the length, the present invention selects every joint length to be the stay section of 1600 millimeters, implements respectively 7 joints, 14 joints and 28 joints and three kinds of test comparisons, the comparative results obtained are as shown in table 1:

[0041] Table 1 Comparison of the effects of different residence periods on the dispersibility of carbon black

[0042]

[0043] From the comparison results in the above table, it can be seen that lengthening the residence period can increase the toluene transmittance of pigment carbon black products, reduce the content of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com