Bottom water tank for irregular casting device

A bottom water tank and special-shaped technology, which is applied in the field of bottom water tanks for special-shaped melting and casting devices and casting structural components, can solve the problems of poor contact between the bottom plate and the crystallizer, affecting the casting effect, complex structure, etc., to avoid electric breakdown and good casting effect , to ensure the effect of casting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

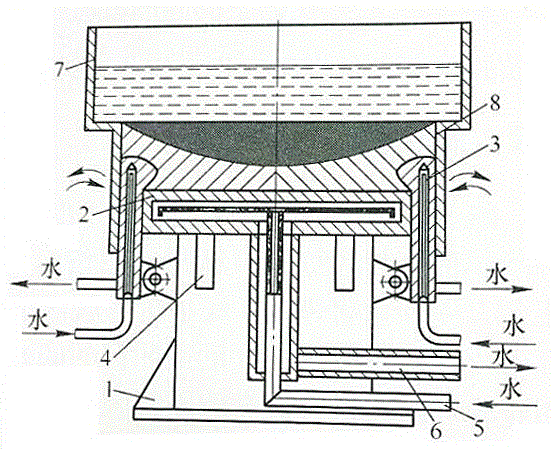

[0013] Example 1 : see figure 1 , a bottom water tank for a special-shaped melting and casting device, the bottom water tank includes a support 1, a working plate 2 arranged on the support 1, cooling fixtures 3 are provided on both sides of the working plate 3, and a cooling fixture 3 is provided on one side of the support 1. The water pipe 5 is provided with an outlet pipe 6 above the water inlet pipe, and a crystallizer 7 is provided above the working plate. In order to introduce and discharge cooling water, a water inlet pipe is arranged on one side of the bracket, and a water outlet pipe is arranged above the water inlet pipe. The water inlet pipe and the water outlet pipe are welded on the bracket or fixed on the bracket by a gasket. The overall structure is ingeniously designed, compact, and low in cost, and the bottom water tank can ensure good contact between the bottom plate and the mold, avoid electrical breakdown, and ensure good casting results.

Embodiment 2

[0014] Example 2 : see figure 1 , as an improvement of the present invention, the bottom water tank further includes a gasket, and the gasket is arranged on the bracket 1 . The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0015] Example 3 : see figure 1 , as an improvement of the present invention, the shape of the working plate 2 is one of flat, concave and convex. In this technical solution, the working plate 2 bears the heat load and electric load of the bottom plate, and the shape of the working plate is set as one of flat, concave, and convex, so as to form the required shape of the lower part of the electroslag ingot. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com