Preparation method of Ag-SiO2-Ag nanosphere array

An ag-sio2-ag and nanosphere technology, which is applied in the field of nanomaterial preparation and Raman spectroscopy detection application, can solve the problems that core-shell nanoparticles are difficult to uniformly disperse, SiO2 is difficult, and the substrate is not firmly bonded. The effect of enhancing sensitivity and improving light permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

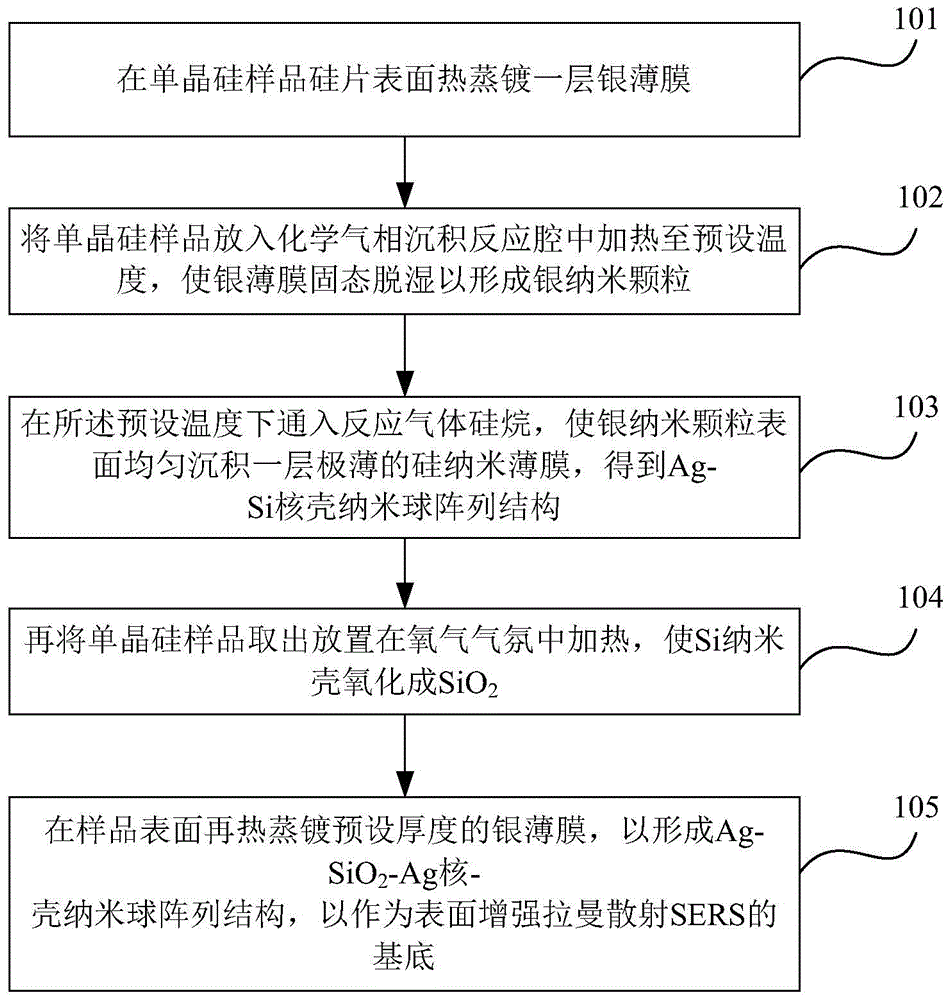

[0032] Such as figure 1 Shown is an Ag-SiO 2 -Flow chart of the preparation method of Ag nanosphere array, the method includes:

[0033] 101. A layer of silver film is thermally evaporated on the surface of a single crystal silicon sample silicon wafer;

[0034] 102. Put a single crystal silicon sample into a chemical vapor deposition reaction chamber and heat it to a preset temperature, so that the silver film is dehumidified in a solid state to form silver nanoparticles;

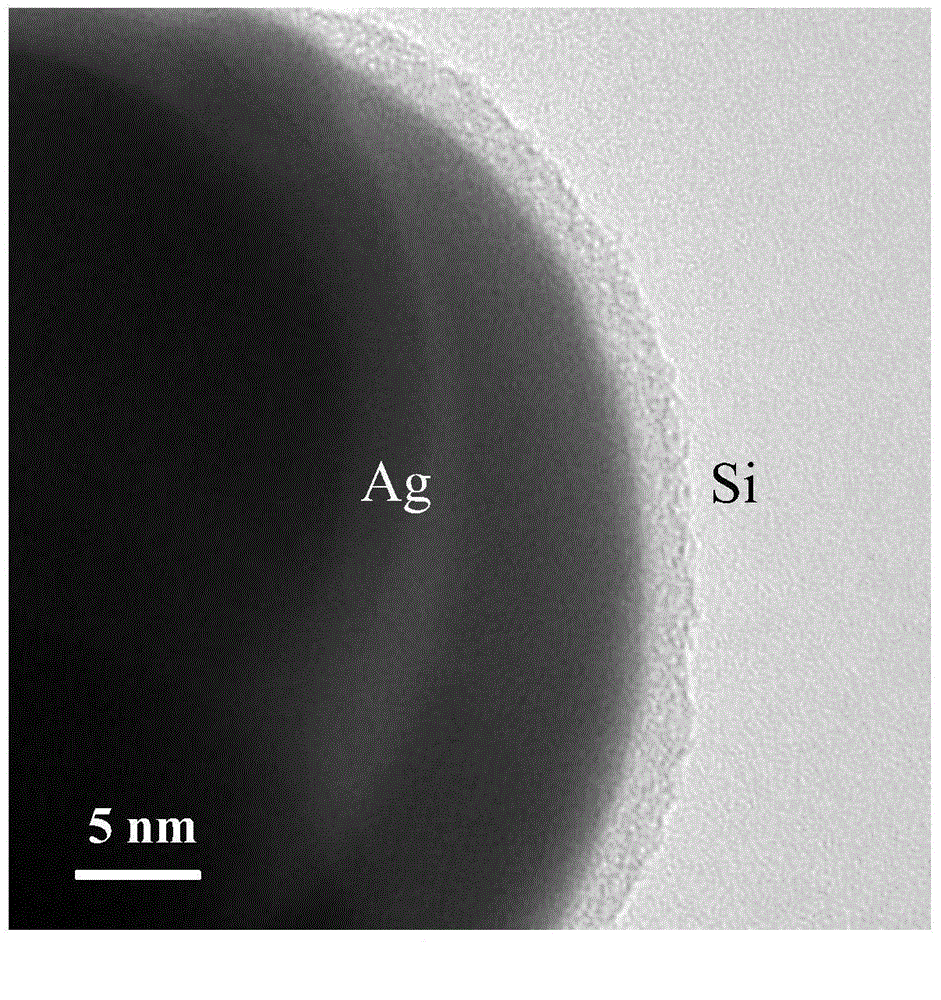

[0035] 103. Pass the reaction gas silane at the preset temperature, so that a very thin silicon nano film is uniformly deposited on the surface of the silver nano particles to obtain an Ag-Si core-shell nanosphere array structure;

[0036] 104. Take out the single crystal silicon sample and place it in an oxygen atmosphere and heat it to oxidize the Si nanoshell to SiO 2 ;

[0037] 105. Re-evaporate a silver film with a preset thickness on the surface of the sample to form Ag-SiO 2 -Ag core-shell nanosphere array st...

Embodiment 1

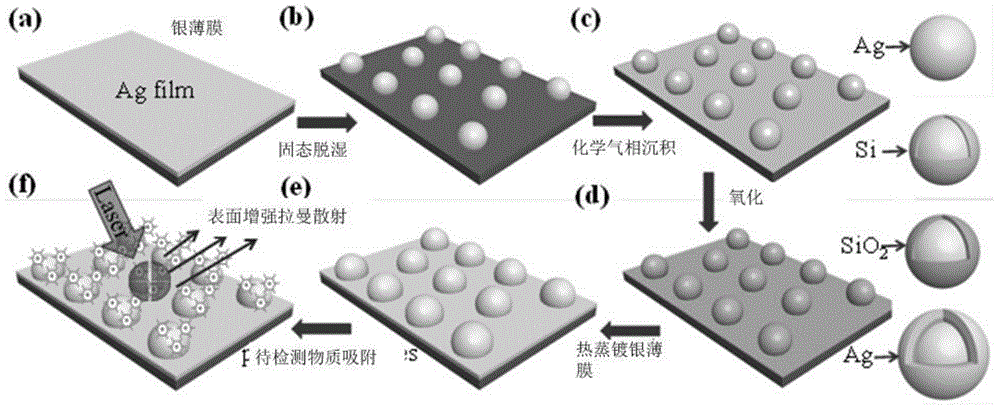

[0057] This embodiment provides a method for preparing a surface Raman enhanced active substrate based on chemical vapor deposition. The preparation process is as follows: figure 2 As shown, (a) a layer of Ag film is thermally evaporated on a smooth silicon substrate, (b) is heated and annealed in a CVD reaction chamber, so that Ag nanoparticles are formed on the surface of the silicon substrate, and (c) a reaction chamber is introduced Gas to obtain the Ag-Si core-shell nanosphere array, (d) take the sample out and place it in an oxygen atmosphere and heat it to obtain Ag-SiO 2 Core-shell nanosphere array, (e) a layer of Ag film is thermally evaporated to obtain Ag-SiO 2 -Ag core-shell nanosphere array SERS substrate, (f) the substance to be detected is adsorbed on the SERS substrate for Raman detection.

[0058] The technical scheme of the present invention will be further explained below.

[0059] Pre-treatment: ultrasonic cleaning 2.5cm×5cm silicon wafer according to the steps ...

Embodiment 2

[0066] This embodiment provides a method for preparing a surface Raman enhanced active substrate based on chemical vapor deposition. The preparation process is as follows: figure 2 As shown, (a) a layer of Ag film is thermally evaporated on a smooth silicon substrate, (b) is heated and annealed in a CVD reaction chamber, so that Ag nanoparticles are formed on the surface of the silicon substrate, and (c) a reaction chamber is introduced Gas to obtain the Ag-Si core-shell nanosphere array, (d) take the sample out and place it in clean air for heating and oxidation to obtain Ag-SiO 2 Core-shell nanosphere array, (e) A layer of Au film is thermally evaporated to obtain Ag-SiO 2 -SERS substrate of Au core-shell nanosphere array, (f) the substance to be detected is adsorbed on the SERS substrate for Raman detection.

[0067] The technical scheme of the present invention will be further explained below.

[0068] Pre-treatment: ultrasonic cleaning 2.5cm×5cm silicon wafer according to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com