Process method for preparing NiCr wear-resistant coating on copper surface

A process method and wear-resistant coating technology, which is applied in the direction of metal material coating process, coating, etc., can solve the problems of high toxicity, cumbersome process, high porosity of coating, etc., and achieve the effect of strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

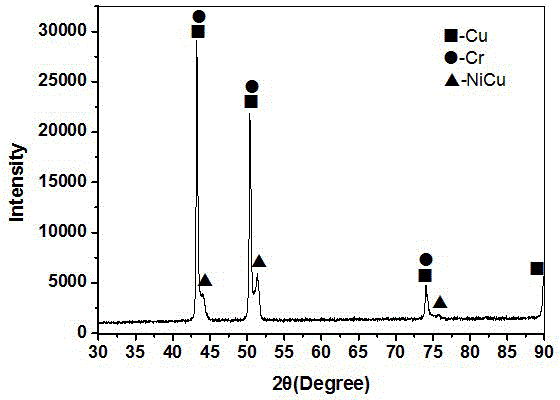

Image

Examples

Embodiment 1

[0027] 1): surface pretreatment: use 400-1200 # After grinding step by step with sandpaper, put the sample in acetone solution for ultrasonic-assisted degreasing and cleaning for 3 minutes, then rinse with deionized water and dry it for later use.

[0028] 2): Deposition electrode surface pretreatment: the selected pure Ni (purity greater than 99.9wt%, the same as the following examples) and pure Cr (purity greater than 99.9wt%, the same as the following examples) electrode rods (both diameters are 3mm) Put it in an acetone solution for ultrasonic-assisted degreasing and cleaning for 5 minutes, then rinse with deionized water and dry it for later use.

[0029] 3): The preparation process of the coating: use the selected copper sample as the base material, as the cathode in the deposition process, connect the cathode of the power supply equipment, use the Ni rod as the deposition electrode, set the deposition process parameters, and the deposition voltage is 80V. The frequency...

Embodiment 2

[0032] 1): Surface pretreatment: Use 400-1200 # Sandpaper was used to grind step by step, put the sample in acetone solution for ultrasonic-assisted degreasing and cleaning for 5 minutes, and then rinse with deionized water and dry it for later use.

[0033] 2): Deposition electrode surface pretreatment: the selected pure Ni (purity greater than 99.9wt%, the same as the following examples) and pure Cr (purity greater than 99.9wt%, the same as the following examples) electrode rods (both diameters are 2mm) Put it in an acetone solution for ultrasonic-assisted degreasing and cleaning for 5 minutes, then rinse with deionized water, and dry it for later use.

[0034]3): The preparation process of the coating: use the selected copper sample as the base material, as the cathode during the deposition process, connect the cathode of the power supply equipment, use the Ni rod as the deposition electrode, set the deposition process parameters, the deposition voltage is 90V, and the freq...

Embodiment 3

[0037] 1): surface pretreatment: use 400-1200 # Sandpaper was used to grind step by step, put the sample in acetone solution for ultrasonic-assisted degreasing and cleaning for 5 minutes, and then rinse with deionized water and dry it for later use.

[0038] 2): Deposition electrode surface pretreatment: the selected pure Ni (purity greater than 99.9wt%, the same as the following examples) and pure Cr (purity greater than 99.9wt%, the same as the following examples) electrode rods (both diameters are 3mm) Put it in an acetone solution for ultrasonic-assisted degreasing and cleaning for 5 minutes, then rinse with deionized water, and dry it for later use.

[0039] 3): The preparation process of the coating: use the selected copper sample as the base material, as the cathode in the deposition process, connect the cathode of the power supply equipment, use the Ni rod as the deposition electrode, set the deposition process parameters, and the deposition voltage is 80V. The freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com