Stone-like foamed cement thermal insulation and decoration integrated board and manufacturing method thereof

A foamed cement and foamed cement layer technology, applied in chemical instruments and methods, hydraulic material layered products, layered products, etc., can solve the problems of high brittleness, high stone processing cost, easy cracking and falling, etc. , to achieve the effect of improving mechanical properties, reducing comprehensive costs and facilitating the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

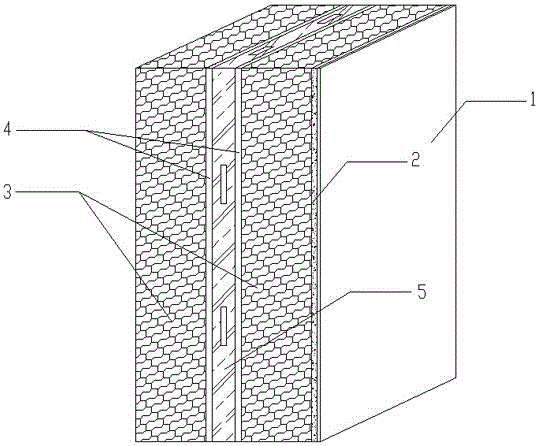

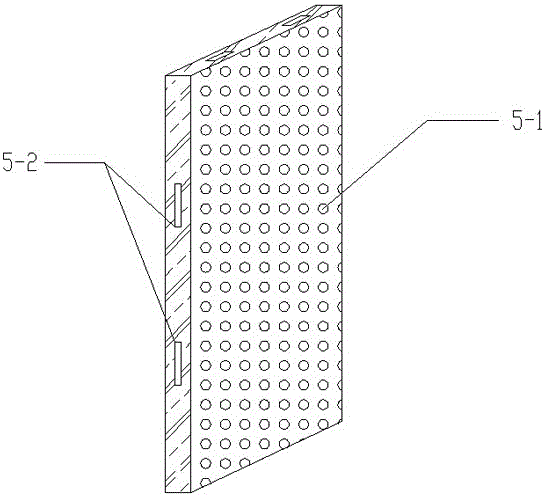

[0022] Embodiment: Stone-like foamed cement thermal insulation and decoration integrated board and its production method are used for external thermal insulation technology of external walls during engineering construction, such as figure 1 , figure 2 As shown, the thermal insulation and decoration integrated board includes calcium silicate board foamed cement composite board, which is composed of glass fiber alkali-resistant grid cloth 4, calcium silicate board 5 and foamed cement 3, and the calcium silicate board 5 Both sides are coated with glass fiber alkali-resistant grid cloth 4 as an anti-cracking layer. The four sides of the calcium silicate board 5 are provided with grooves 5-2, and the surface layers on both sides are provided with a number of holes 5-1. 5 is fixed in the middle of the mould, and is fixed in the slot 5-2 in contact with the mould.

[0023] The foamed cement slurry is based on the water-cement ratio of 0.6, and the following materials are based on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com