Manufacturing method of faucet

A manufacturing method and faucet technology, which is applied in the field of faucet fittings, can solve problems such as harsh casting environment, easy to be scalded, and corroded, so as to improve production operability and external aesthetics, reduce product defect rate, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

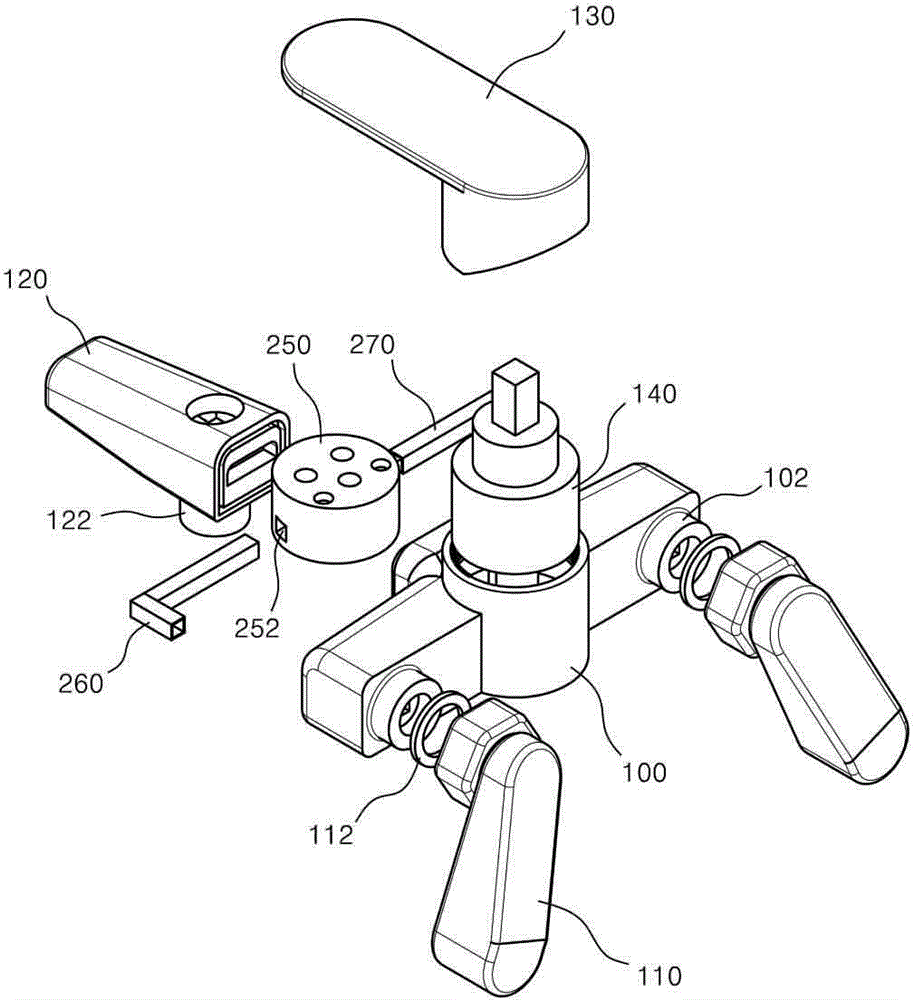

[0063] Figure 1 to Figure 2 It is an exploded perspective view of the faucet fittings manufactured by the faucet fittings manufacturing method according to an embodiment of the present invention, Figure 6 It is a process flow diagram of a method for manufacturing faucet fittings according to an embodiment of the present invention, Figure 1 to Figure 2 The same constituent elements are assigned the same reference numerals.

[0064] Referring to the above drawings, it can be seen that the faucet fittings manufacturing method according to one embodiment of the present invention includes: accessories preparation step S11, cold and hot water flow pipe joining step S12, double injection molding step S13 and assembly step S14.

[0065] First, prepare accessory S11 for manufacturing faucet fittings. The accessories here include metal accessories and non-metal accessories. The metal fittings include: an eccentric sleeve 110 connected to the cold and hot water pipes (not shown) on t...

Embodiment 2

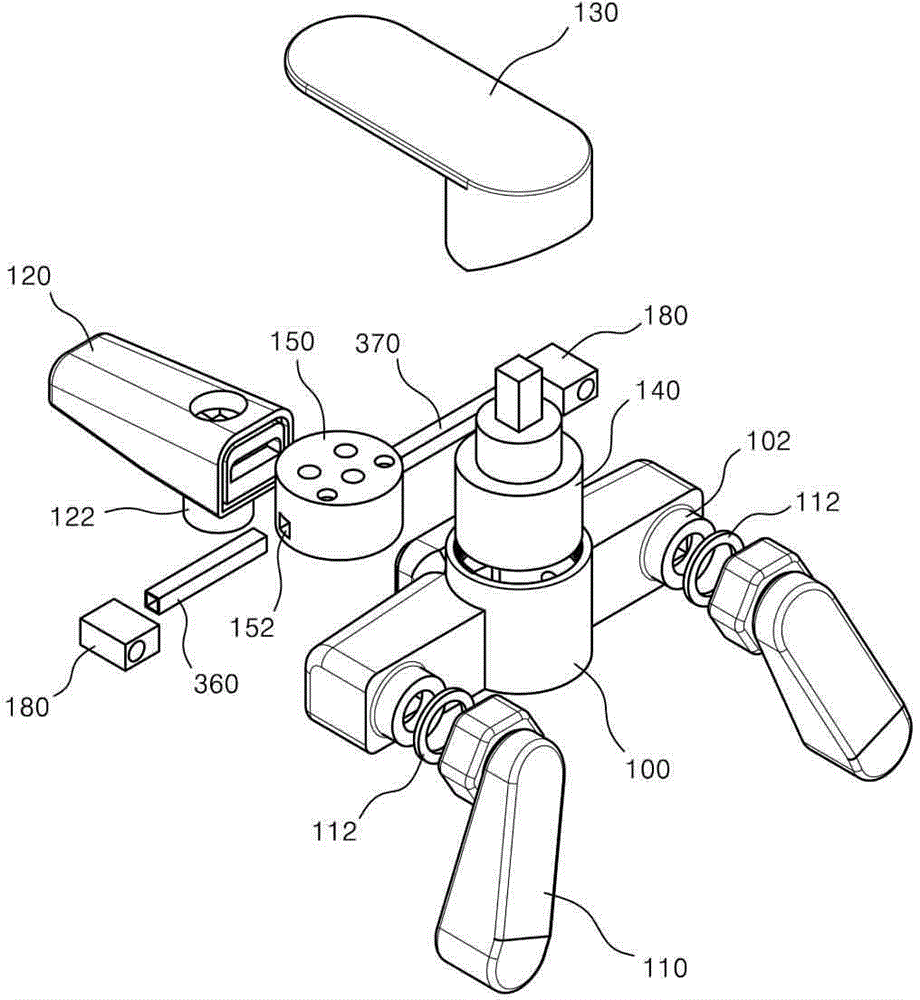

[0086] image 3 is an exploded perspective view of a faucet fitting manufactured by a faucet fitting manufacturing method according to another embodiment of the present invention, in image 3 neutralize Figure 1 to Figure 2 The same constituent elements are given the same reference numerals.

[0087] Referring to the above drawings, it can be seen that the manufacturing method of the faucet fittings according to another embodiment of the present invention is the same as the manufacturing method of the faucet fittings described in the foregoing embodiment 1, including: a step of preparing accessories; a step of combining cold and hot water flow pipes; a double injection molding step; and an assembly step.

[0088] Prepare metallic and non-metallic fittings in the fitting preparation step.

[0089] The metal accessories include: an eccentric sleeve 110 , a discharge pipe 120 , a water outlet 122 and an opening and closing handle 130 .

[0090] In addition, the non-metal fitt...

Embodiment 3

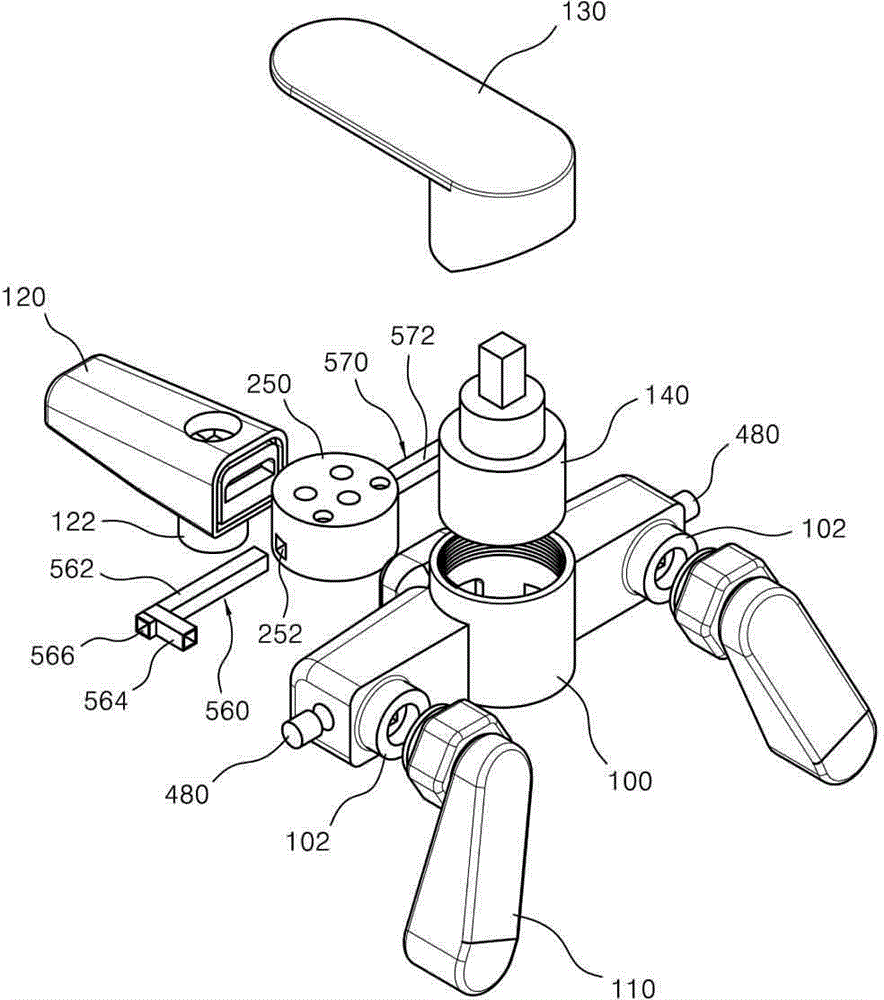

[0110] Figure 4 to Figure 5 is an exploded perspective view of a faucet fitting manufactured by a faucet fitting manufacturing method according to another embodiment of the present invention, in Figure 4 to Figure 5 neutralize Figure 1 to Figure 2 The same constituent elements are assigned the same reference numerals.

[0111] Referring to the above drawings, it can be seen that the manufacturing method of the faucet fittings according to another embodiment of the present invention is the same as the manufacturing method of the faucet fittings described in the foregoing embodiment 1, including: a step of preparing accessories; a step of combining cold and hot water flow pipes; a double injection molding step; and an assembly step.

[0112] Prepare metallic and non-metallic fittings in the fitting preparation step.

[0113] Metal fittings include: eccentric sleeve 110 , discharge pipe 120 , water outlet 122 , opening and closing handle 130 .

[0114] The non-metal fitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com