Method for prolonging service life of quantum dot LED

A quantum dot light-emitting and diode technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as hindering the commercial application of QD-LED, limiting the life of QD-LED devices, and unable to effectively suppress fluorescent flickering. The ability to resist photobleaching, suppress fluorescence scintillation, and improve lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

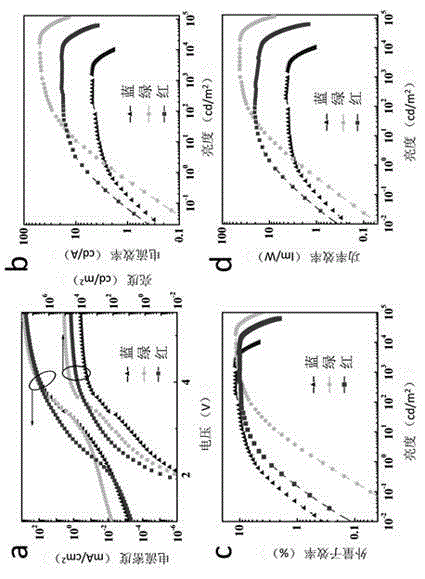

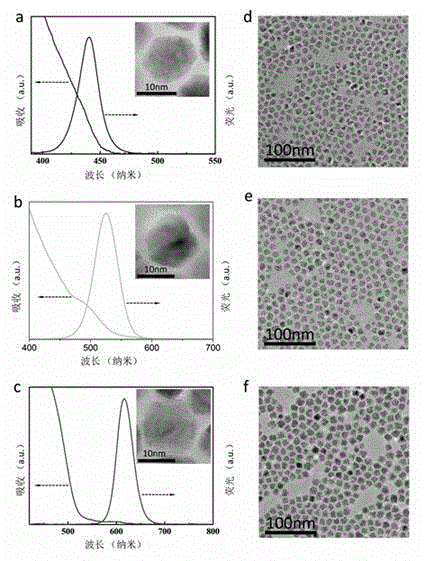

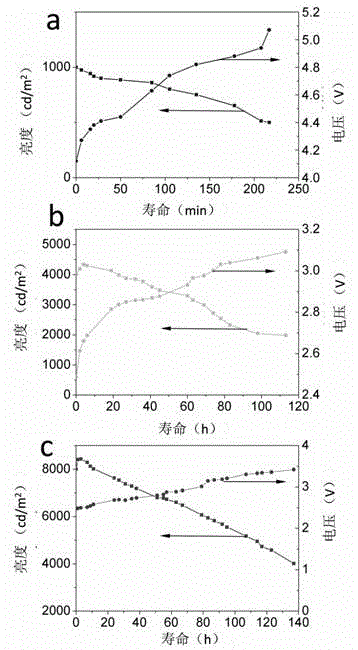

Embodiment 1

[0020] A method for improving the lifespan of a quantum dot light-emitting diode, the quantum dot used as a light-emitting layer has a shell-to-core volume ratio of 62:1. The specific preparation method is as follows:

[0021] Use the ITO glass of the cleaned pattern painting with an ultraviolet-ozone treatment machine (UV / O 3 ) for 15 minutes, and then a 30 nm PEDOT:PSS film was spin-coated on an ITO glass substrate at a speed of 5500 rpm as a hole injection layer by the method of spin coating. The ITO glass substrate with spin-coated PEDOT:PSS film was dried in air at 150°C for 15 min, and then transferred to a glove box to spin-coat a 40 nm TFB chlorobenzene solution with a mass concentration of 1.5 wt% as a hole transport layer. , and dried in a glove box at 110°C for 30min. Continue to spin-coat blue "giant shell" quantum dots ZnCdSe / ZnS with a concentration of 18mg / mL (thickness about 37nm) as the light-emitting layer, and then prepare a zinc oxide (ZnO) electron trans...

Embodiment 2

[0025] A method for improving the lifespan of a quantum dot light-emitting diode, the quantum dot used as a light-emitting layer has a shell-to-core volume ratio of 64:1. The specific preparation method is as follows:

[0026] Use the ITO glass of the cleaned pattern painting with an ultraviolet-ozone treatment machine (UV / O 3) for 15 minutes, and then a 30 nm PEDOT:PSS film was spin-coated on an ITO glass substrate at a speed of 5500 rpm as a hole injection layer by the method of spin coating. The ITO glass substrate with spin-coated PEDOT:PSS film was dried in air at 150°C for 15 min, and then transferred to a glove box to spin-coat a 40 nm TFB chlorobenzene solution with a mass concentration of 1.5 wt% as a hole transport layer. , and dried in a glove box at 110°C for 30min. Continue to spin-coat green "giant-shell" quantum dots ZnCdSe / ZnSe / ZnS (thickness about 37nm) with a concentration of 18mg / mL as the light-emitting layer, and then prepare a zinc oxide (ZnO) electron ...

Embodiment 3

[0030] A method for improving the lifespan of a quantum dot light-emitting diode, the quantum dot used as a light-emitting layer has a shell-to-core volume ratio of 72:1. The specific preparation method is as follows:

[0031] Use the ITO glass of the cleaned pattern painting with an ultraviolet-ozone treatment machine (UV / O 3 ) for 15 minutes, and then a 30 nm PEDOT:PSS film was spin-coated on an ITO glass substrate at a speed of 5500 rpm as a hole injection layer by the method of spin coating. The ITO glass substrate with spin-coated PEDOT:PSS film was dried in air at 150°C for 15 min, and then transferred to a glove box to spin-coat a 40 nm TFB chlorobenzene solution with a mass concentration of 1.5 wt% as a hole transport layer. , and dried in a glove box at 110°C for 30min. Continue to spin-coat red "giant-shell" quantum dots CdSe / ZnCdS / ZnS (thickness about 37nm) with a concentration of 15mg / mL as the light-emitting layer, and then prepare a zinc oxide (ZnO) electron tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com