Preparation process of superconductive Josephson junction covered by edge of in-situ three-layer film

A technology of edge coverage and preparation process, applied in the field of semiconductor, can solve the problems of increasing process steps, unstable oxide layer, unfavorable integration scale of patterns, etc., and achieves the effect of high quality and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

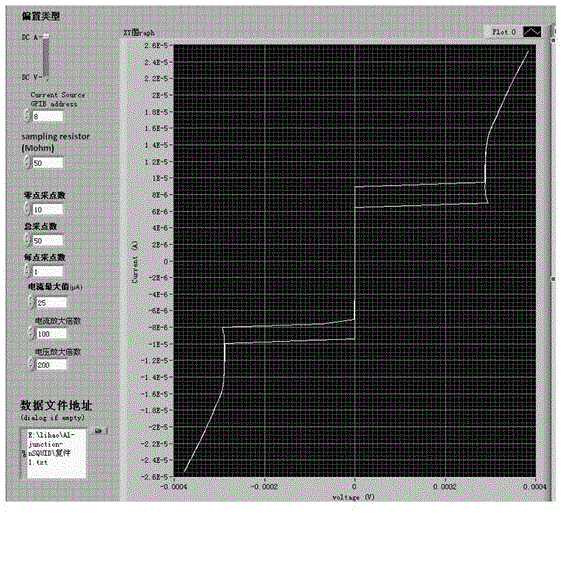

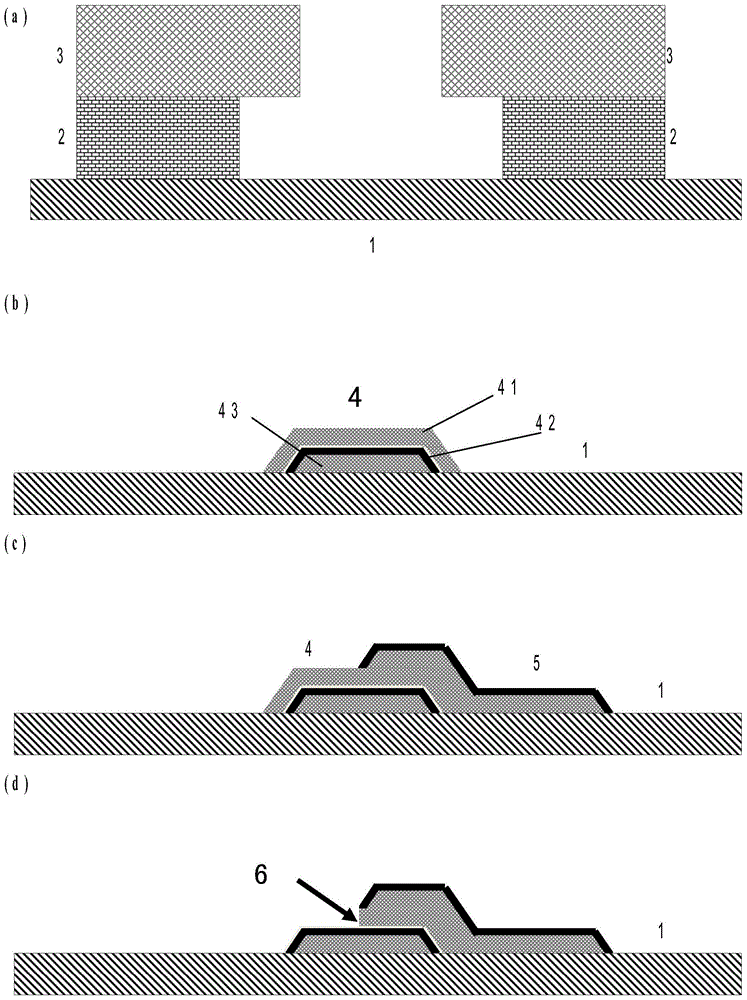

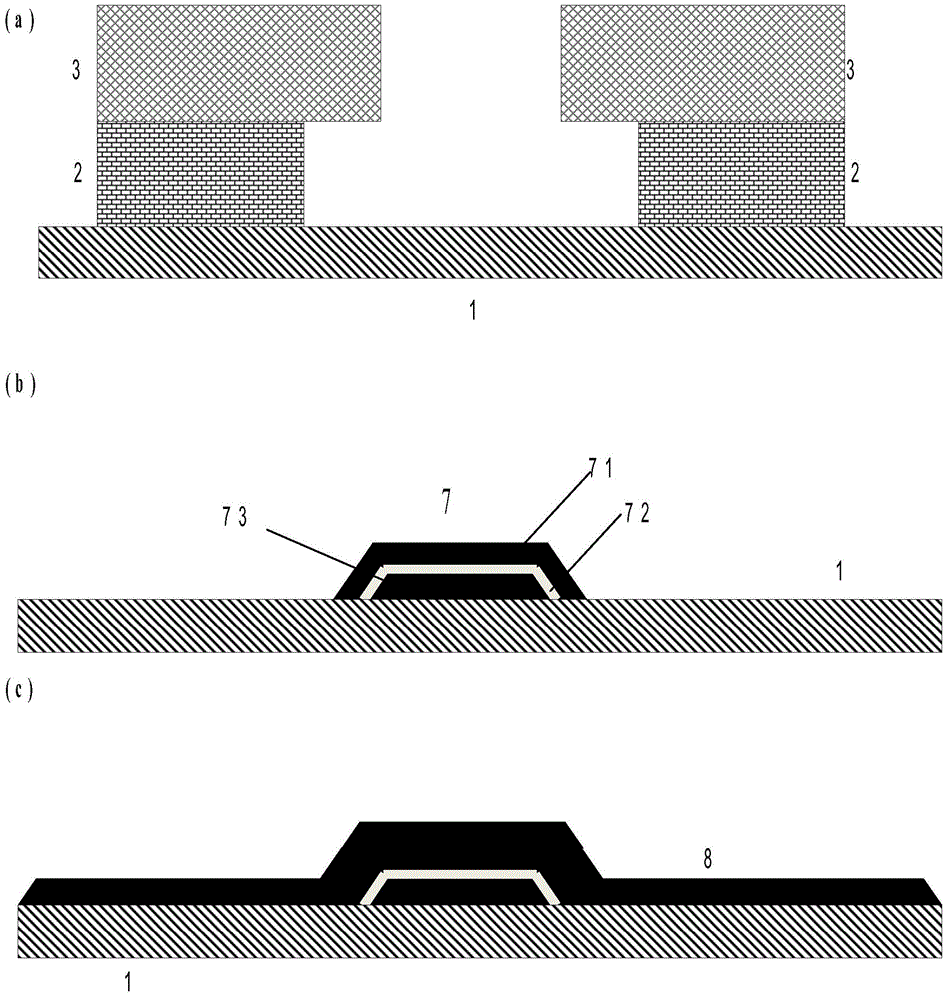

[0030] The invention describes a process for preparing a Josephson junction based on a microelectronic planar process, and its basic process flow consists of three parts: in-situ growth of three layers of film, growth of a lead layer, photolithography and etching to define a junction region. It differs in specific steps and details for Nb Josephson junction and Al Josephson junction. Their preparation procedures are as follows figure 1 and figure 2 shown.

[0031] Nb Josephson junction preparation process:

[0032] (1) Carry out double-layer glue photolithography on sapphire or the silicon chip substrate 1 that surface is thermally oxidized, be respectively upper layer photoresist 3 and lower layer photoresist 2, form good undercut, as figure 1 (a) shown. The process conditions of different photolithography process lines are different. A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com